Leak Detection: An HVAC/R Workforce Enablement Solution

For more than three decades, the HVAC/R industry has operated with roughly 350,000 – 425,000 active Air conditioning and refrigeration technicians nationwide, about the same number we had thirty years ago.

In that same time, the installed base of equipment has exploded, growing from about 45 million systems to more than 200 million across supermarkets, data centers, commercial facilities, and a wide variety of buildings.

That imbalance defines today’s challenge.

The industry faces significant challenges, including technician shortages, regulatory compliance, and the need for accurate leak detection.

Building foundational skills through workforce development programs and training is essential to address these challenges and ensure technicians are equipped with the necessary communication, technical, and soft skills. We’ve scaled the technology, but not the people to sustain it.

We’ll help you get up and running, integrate the detector into your workflow, and monitor the data for you.

Even as new technicians enter the trade, retirements nearly offset every gain, leaving an industry that’s running faster just to stay even.

This massive growth, combined with stringent EPA 608 compliance requirements and the need for precise refrigerant handling, has turned every leak into a regulatory and financial liability.

Every unnecessary trip isn’t just a cost; it’s an exposure: wasted labor, potential non-compliance, and preventable emissions.

The first step in effective leak detection is recognizing early signs of a problem and beginning the troubleshooting process promptly.

These inefficiencies also negatively impact energy efficiency, increasing both operational costs and environmental impact.

Advanced leak detection solutions help reduce downtime by enabling faster, more accurate repairs, which is critical for maintaining continuous operations.

Avoiding unnecessary expenses and maximizing savings through effective leak detection helps save money for building owners and operators.

Truck rolls are up, downtime is up, and so is fatigue.

Leak detection sits at the center of this crisis. It’s the most time-intensive, regulated, and environmentally critical part of the technician’s job — and the most logical place to create leverage.

Detecting leaks in refrigerants is especially important to minimize environmental harm and meet regulatory requirements.

To meet demand and compliance obligations without burning out the workforce, we need to amplify technician capacity, not multiply truck rolls.

Table of Contents

ToggleUnderstanding Refrigerant Leaks

Refrigerant leaks determine system performance. They define efficiency, safety, and equipment life.

Effective detection isn’t just a technical necessity: it’s protection against failure, rising costs, and environmental damage.

Today’s HVAC professionals need speed and precision. Performance and compliance depend on it.

Leaks emerge from improper installation, installation errors, missed maintenance, and natural wear. Small leaks create outsized problems. Systems work harder.

Energy consumption climbs. Efficiency drops. The result: higher bills, frequent breakdowns, and safety risks for occupants.

Detection requires skill and precision tools. HVAC technicians use proven methods: soapy water, gas sounds, leak detectors, electronic detectors, and infrared sensors.

Advanced systems provide real-time data and instant alerts. Technicians monitor pressure changes as key indicators of leaks or system issues.

Sensitive electronic detectors offer high reliability in detecting refrigerant leaks. Technicians act quickly. Downtime disappears. Minor issues stay minor.

Not every method delivers equally. False alarms persist. Unnecessary calls waste time and resources. Industry leaders choose reliable, accurate solutions.

They minimize noise. They maximize insight.

Regular maintenance, proper evacuation, and nitrogen pressure testing prevent leaks.

Refrigerant emissions accelerate climate change.

Quick detection and repair matter. HVAC professionals protect the environment. They maintain compliance. Regulations tighten. Performance standards rise.

Understanding leaks (detecting them, preventing them) drives efficient, safe, sustainable operation.

Reliable technology works. Best practices deliver. Regular maintenance protects. Technicians identify and repair before problems escalate. Operating costs drop. Equipment lasts longer. Environmental impact shrinks.

This is performance and responsibility, refined.

→ Discover our HVAC/R Knowledge Hub

AKO × Carbon Connector: Closing the Capability Gap

That’s where AKO and Carbon Connector come in.

Our partnership is built around one idea: leak detection should be a workforce enablement solution, not a technology sale.

We focus on building foundational knowledge and practical skills for technicians, helping them develop the expertise needed for success in leak detection and compliance.

Our model also aims to enhance the effectiveness of leak detection and workforce enablement by leveraging advanced support and technology.

It’s a simple formula: start with great tech, layer in back-end analytics, evaluation, and support, and add a serious commitment to solving problems.

How the Model Works

Detection With Context

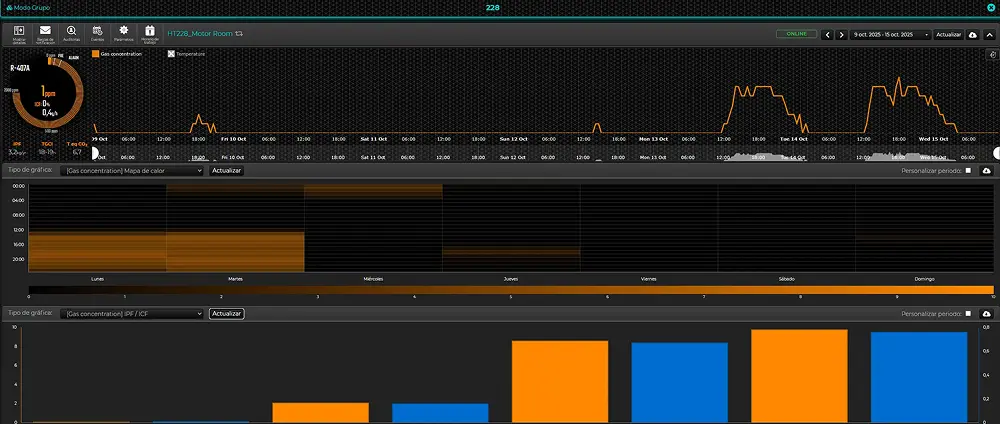

AKO’s precision leak detection technology identifies anomalies before they escalate.

Carbon Connector works with AKO engineers and analytics experts (in real time) interprets the data, producing a Leak Profile that clarifies what’s happening, where to look, and whether it truly requires a site visit. (AKO has a patent for this.)

This process is supported by integrated software that delivers real-time analytics and actionable insights.

Support, Not Automation

We don’t replace technicians: we enable them. Our team provides live guidance and context so that when a truck rolls, it rolls with purpose.

Each call becomes smarter, shorter, and fully documented for regulatory confidence.

Precision Deployment

Every unnecessary trip burns fuel, time, and morale.

As a tech myself, I cannot tell you how many meals, recitals, sports events, and social gatherings I have missed because of an emergency call. So this is personal.

By validating each signal, we convert three exploratory visits into one verified repair, a direct productivity gain, and a compliance safeguard.

Together, these elements form a comprehensive workforce enablement solution.

We’ll help you get up and running, integrate the detector into your workflow, and monitor the data for you.

Proof in Action: From Signal to Solution

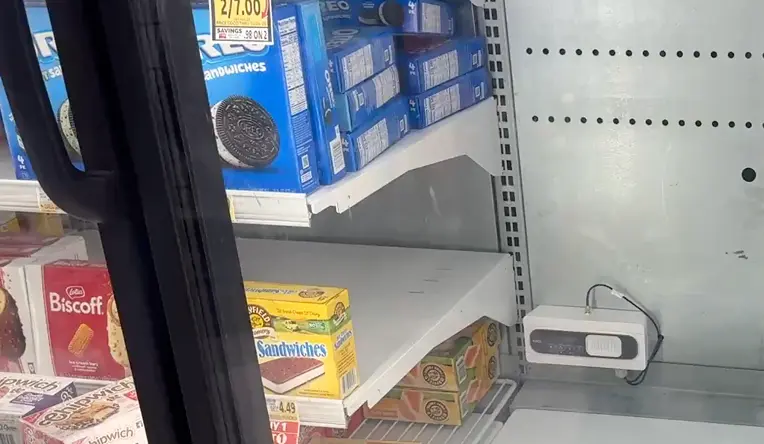

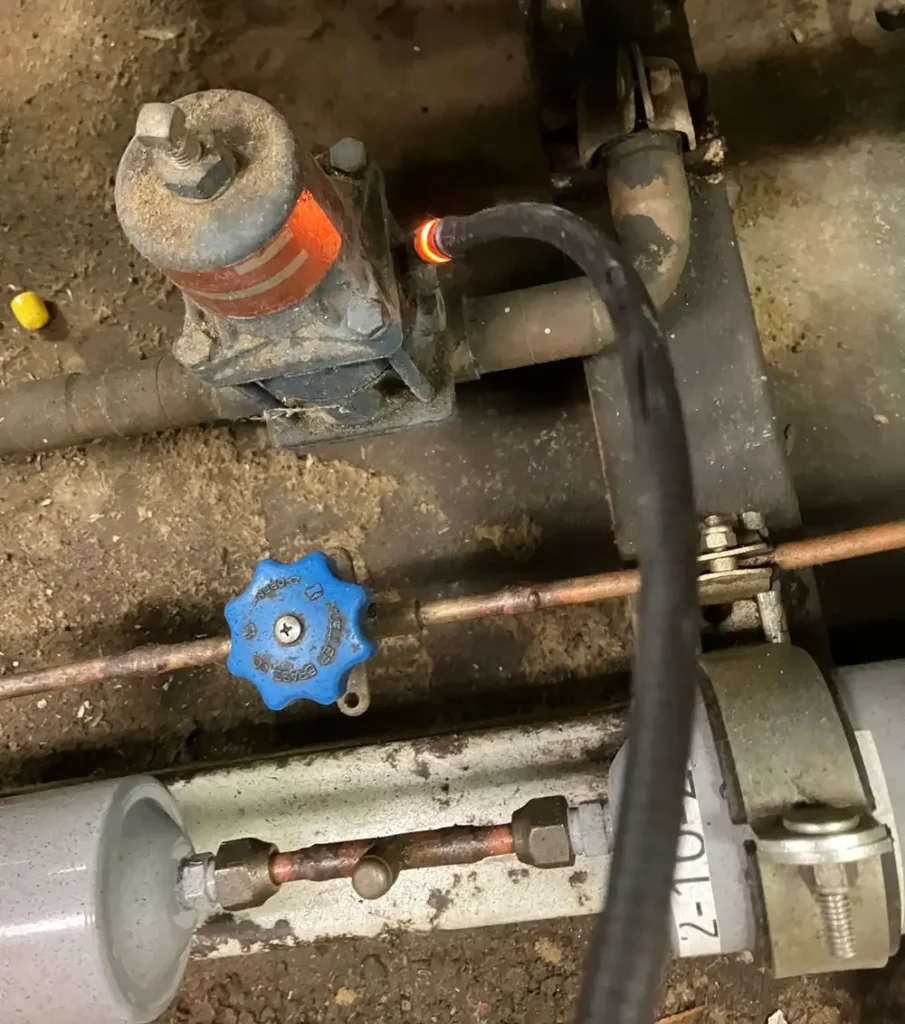

Recently, one store’s case circuit exhibited a subtle anomaly.

AKO’s sensors captured the deviation, detecting a leak as small as 0.1 oz/h, an impressively tiny leak rate that highlights the system’s exceptional sensitivity and early detection capability.

This detail is visible in the image but deserves special emphasis. Detecting such a small leak means that over two days (24 hours of total leakage), the system only lost about 2.4 oz before the repair was made.

This early detection prevented the need to recharge a bottle and avoided a potentially larger refrigerant loss.

The leak was located in a motor room, a high-risk area where leaks can escalate quickly and cause significant breakouts.

By catching it early, this repair likely saved hundreds of pounds of refrigerant from escaping. The leak pattern was beginning to escalate, so timely intervention was critical.

Thanks to our patented technology, this KPI goes beyond simple parts-per-million (ppm) detection, providing precise leak rate measurements that empower proactive maintenance.

Moreover, the system’s detailed information on when, how much, and where the leak occurs has been shown to reduce leak location and repair time by up to 80%, according to feedback from several installers who have used our solution.

This reduction in diagnostic and repair time not only saves money but also minimizes downtime and environmental impact.

⚠️ One signal. One roll. One fix.

That’s what workforce enablement looks like in practice.

- The leak was profiled, the time, the pattern, and the profile were all communicated to the tech, who was scheduled to do the work:

2. The tech had a scheduled visit:

3. The area of the leak was evaluated

4. The Leaks were spotted and confirmed

The Hidden Complexity: Why Leak Detection Matters in 10,000 Feet of Pipe

A typical 50,000-square-foot (approximately 5,000 m²) grocery store presents a complex challenge when it comes to locating refrigerant leaks.

With an extensive network of refrigeration systems, including numerous evaporators, condensers, and refrigerated cases spread throughout the facility, pinpointing the exact source of a leak can be daunting.

The complexity arises not just from the sheer size but from the many potential failure points hidden within mechanical connections, valves, and piping that weave through ceilings, walls, and refrigerated units.

This complexity underscores the critical value of advanced leak detection solutions that provide detailed information on when a leak occurs, how much refrigerant is escaping, and precisely where the leak is located.

A key breakthrough in our approach, protected by a patented technology, integrates spatial data (such as the exact location of each detector and the measured space it covers) into a hierarchical evaluation process.

This method allows the system to analyze the type, proximity, and volume of the leak with remarkable accuracy, enabling technicians to focus their efforts efficiently, reducing time spent searching and ensuring faster, more precise repairs.

📌 Effectively managing leaks in such a large and intricate environment is essential

to maintaining system performance, energy efficiency, and compliance, while minimizing downtime and environmental impact.

The Challenge of Finding a Leak You Can’t See

Leaks don’t behave like light switches: they’re slow, evolving, and often hidden within insulation, walls, or ceilings.

In a supermarket, a pinhole leak can release gas gradually for weeks before it’s detectable by sight or pressure drop, leading to significant refrigerant loss, energy inefficiency, and temperature instability long before alarms sound.

Technicians are already stretched thin, and when you combine:

- 10,000+ feet of copper lines,

- hundreds of fittings and joints, and

- dozens of evaporators, condensers, and cases, overhead piping, elbows that go on for days, and tunnels, traps, and walls that obscure access; this becomes an egg hunt of misery.

Or as the rest of the world would call it: a complex ecosystem where finding a single leak can take hours, days, or multiple visits.

No one wants to pay for multiple visits; it can cost easily $4000 to find a hard-to-identify leak if not properly profiled

Even with standard tools like handheld sensors or soap-bubble tests, technicians can only inspect a small portion of that piping per visit, leaving 90% of the system effectively unmonitored between service calls.

Rethinking Success: Measuring by Truck Rolls, Not Devices

For years, success was measured by device count — how many sensors or dashboards were deployed.

That approach created alarm fatigue, ineffective spending, and broken trust.

Technicians drowned in alerts, managers tuned them out, and the industry lost faith in the promise of automation.

Or as the rest of the world would call it: a complex ecosystem where finding a single leak can take hours, days, or multiple visits.

AKO & Carbon Connector are rewriting that script.

We judge ourselves not by hardware volume but by truck rolls avoided, leaks verified, and time-to-repair reduced.

📌 Effectiveness, not inventory, is our currency.

How We Judge Ourselves

At AKO and Carbon Connector, we hold ourselves to a standard that goes beyond dashboards and device counts. We judge success by what we help the workforce see, solve, and prevent.

Our version of scale is reducing leak rates, helping reduce the number of emergency calls, or enhancing food safety.

Every verified leak is a win for the technician who found it, the company that avoided loss, and the environment that avoided unnecessary emissions.

Effective leak detection directly benefits the performance and longevity of the air conditioning system, ensuring it operates efficiently and reliably.

Proper ventilation is also essential, as it maintains system efficiency and supports healthy indoor air quality.

Accurate leak detection helps prevent exposure to toxic substances, making safety a top priority for our clients. Every leak identified through our process represents time saved, compliance secured, and trust restored.

That’s why our model measures both prevention and precision, the discipline to stop wasted effort, and the insight to pinpoint real problems before they spiral into costly failures.

The Metrics That Matter

| Metric | Definition | Why It Matters |

|---|---|---|

| Leaks Identified | Verified leak events located and resolved through AKO + Carbon Connector workflows. | The ultimate validation of data integrity, teamwork, and field precision. |

| Truck Rolls Avoided | The duration a leak remains active before detection and repair. | Reduces cost, fuel, emissions, and fatigue, the cornerstone of workforce enablement. |

| Time-to-Resolve | Time from first signal to confirmed repair. | Measures agility and communication between data, facilities, and technicians. |

| First-Time Fix Rate | Percentage of visits that result in immediate, verified resolution. | Reflects signal quality, preparation, and confidence in diagnosis. |

| False Alarm Ratio | Proportion of alerts with no actionable outcome. | Lower ratios mean higher trust and fewer wasted hours. |

| Leak Dwell Time | Duration a leak remains active before detection and repair. | Tracks tangible progress toward sustainability and operational excellence. |

Why These Metrics Matter More Than Ever

These aren’t just performance indicators: they’re proof points for alignment across teams.

When the data team validates a leak and the field confirms it, everyone wins: the technician gains time, the manager gains trust, and the organization gains compliance confidence.

This feedback loop ensures that:

- Every verified leak is documented, shared, and celebrated.

- Every success story strengthens the bond between the people interpreting the data and those repairing the systems.

- Every follow-up is another step toward a workforce that acts faster, smarter, and with greater confidence.

More meals at home, kids’ games attended, and a better work-life balance.

By measuring not only technical outcomes but also the coordination that made them possible, AKO and Carbon Connector have turned performance into participation, and participation into proof of progress.

Finding More, Fixing Smarter

Our performance doesn’t stop at fewer truck rolls: it extends to better truck rolls.

We measure not just how often we can keep trucks parked, but how often we help them arrive at the right place, at the right time, with the right plan.

That means:

- More confirmed leaks were found early.

- Fewer catastrophic losses.

- Faster verification for compliance and cost control.

Every identified leak carries its own ripple effect: energy saved, emissions avoided, product preserved, and technician time redirected toward prevention instead of crisis.

The difference is not incremental; it’s cultural.

Instead of chasing uncertainty, technicians are now acting with confidence, backed by clarity and data that stand up to audit, regulation, and internal performance review.

Why Leaks Identified Is Our North Star

Leak identification is more than a number: it’s a statement of purpose.

It’s the measure that proves the system works, not because it runs quietly, but because it delivers verifiable results.

- It validates the accuracy of AKO’s detection and Carbon Connector’s profiling process.

- It demonstrates tangible ROI: every leak found is a dollar saved and a pound of refrigerant kept out of the atmosphere.

- It redefines accountability, replacing assumptions with evidence and effort with outcomes.

In a world where most solutions compete for attention, we compete for verification.

If we can’t prove a leak was found and fixed, we don’t count it.

The Complete Measure of Effectiveness

Effectiveness = Leaks Identified + Leaks Prevented + Truck Rolls Avoided.

That’s our equation, and it tells the whole story.

It captures the essence of what workforce enablement really means:

- Empowering people with data they can trust.

- Preventing waste before it becomes loss.

- And ensuring that every technician in a shrinking workforce has a clearer, smarter path to success.

This isn’t just performance reporting; it’s a redefinition of operational value.

For years, the industry has equated innovation with devices sold.

We’ve moved on.

Innovation now means fewer wasted steps, faster discoveries, cleaner documentation, and stronger compliance across every site and system.

The Trust Dividend

When the workforce trusts the signal, action follows.

When management trusts the data, investment returns.

When regulators trust the documentation, compliance risk falls.

That is the trust dividend of leak detection done right.

And it’s why we judge ourselves not by noise, but by outcomes:

how many leaks we help identify, how many truck rolls we save, and how many hours we give back to the people who keep cold chains alive.

The measure of success isn’t how loud the alarm sounds; it’s how many problems get solved because of it.

That’s the future we’re building: fewer false starts, more verified wins, and a workforce that finally gets credit for every ounce of refrigerant saved.

Restoring Trust Through Effectiveness

False alarms broke trust.

Fatigue broke morale.

We rebuild both through precision, collaboration, and measurable accountability.

Our rules are simple:

- No alarms without analysis.

- No data without dialogue.

- No truck rolls without reason.

That’s how we measure ourselves, and how we rebuild faith in leak detection as a discipline that protects both compliance and people.

A New Standard for the Industry

Leak detection is no longer a checkbox under EPA 608: it’s the frontline of workforce efficiency and environmental performance.

By focusing on effectiveness (leaks found, leaks prevented, and truck rolls avoided), AKO and Carbon Connector are setting a new standard.

Effectiveness = Leaks Found + Leaks Prevented + Truck Rolls Avoided.

That’s our formula.

That’s our proof.

And that’s how we’re going to help 425,000 technicians do the work of twice that number: not by adding complexity, but by delivering clarity and confidence where it’s needed most.

The future of leak detection isn’t about more devices, it’s about more effective people.

AKO and Carbon Connector are making that future real, one verified signal and one fewer truck roll at a time.