Track your Equipment

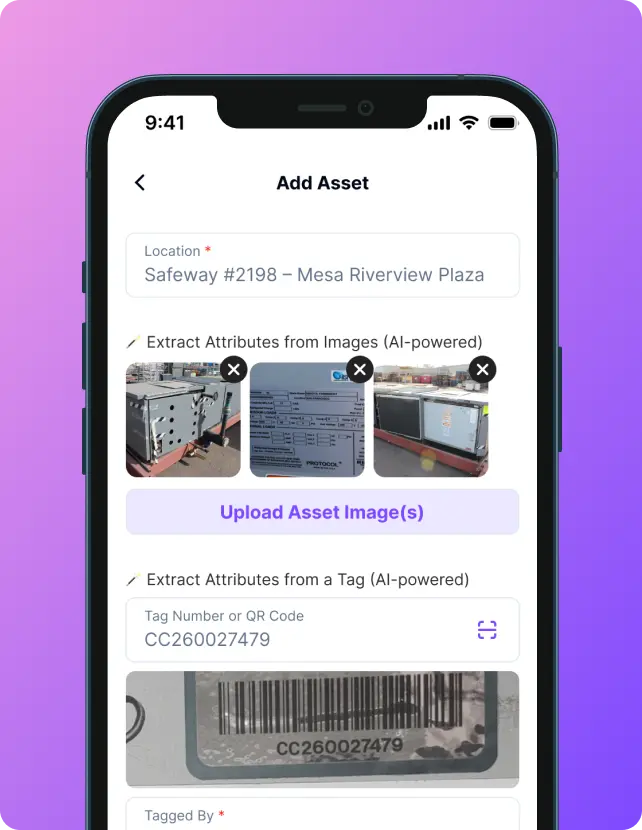

Empower Your Team with Tag Wizard, an intuitive app That Works Anywhere

Stop wasting time and money on lost equipment with the smart asset tracking solution that works anywhere

The Tag Wizard Difference is that we have worked closely with numerous professionals in the field to train our models, delivering Intuitive Workflows

Driven by Smart Scanning Technology with the ability to adapt to various field scenarios or user requirements.

Stop Losing Time and Money

With Outdated Asset Tracking Methods

Is your business hemorrhaging money through misplaced equipment, inefficient spreadsheet tracking, and endless searches for missing assets?

→ Studies show companies lose up to 30% of their valuable assets annually due to poor tracking systems.

Whether you’re managing IT equipment or even software across multiple locations, tracking tools on job sites, or keeping tabs on inventory in warehouses, manual asset management is costing you thousands in replacement costs, wasted productivity, and compliance headaches.

Our mobile asset tracking app transforms this chaos into organized, real-time visibility that saves time and helps you cut costs from day one.

With our solution, you can easily track assets, ensuring quick localization and efficient management.

Forget manual entry. Embrace AI.

asset tagging app

that brings true ✨ AI automation ✨ to the field.Smart Nameplate Scanning (Unique to Tag Wizard)

Just take a picture of equipment nameplates or asset tags, and Tag Wizard's unique AI automatically reads and extracts all the details, filling in your forms instantly and ensuring information is perfectly aligned.

Hands-Free Voice Entry

We know your hands are busy. With talk-to-text functionality, simply tell the app what you're looking at, and it will fill in the asset data while you multitask, phone in one hand, wrench in the other.

Driven by intuitive workflows and field adaptability.

Guided Task and Inspection Lists (Soon!)

Empower your technicians with a structured, step-by-step asset task list linked to specific equipment types. Ensure every inspection, maintenance log, and compliance check is completed accurately and documented perfectly, every time. Easily record and access detailed asset history to improve accountability and support compliance requirements.

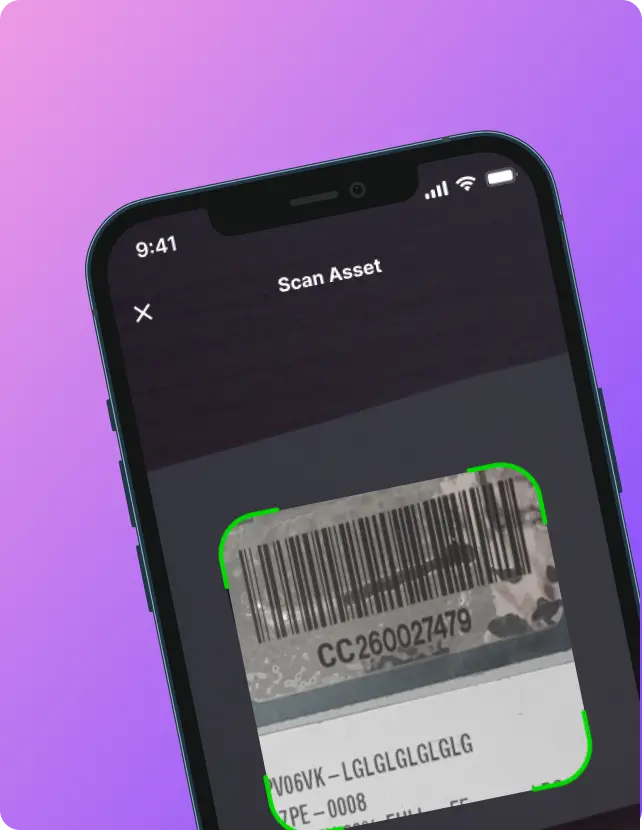

Future-Proof Tagging

Supports instant Barcode and QR code scanning, and is ready for NFC (Near Field Communication) and the latest Bluetooth (BLE) beacons for maximum flexibility and rapid tap-to-read functionality. Tie the Beacon to the asset and close the loop on the types of devices in your workplace or across your entire asset empire

The Tag Wizard Difference: Magic in Every Detail

Our asset management software stands out from traditional asset tracking solutions:

Advanced AI Technology

Our scanning engine reads damaged, dirty, or partially obscured barcodes that other asset tracking apps struggle with

Smart Auto-Sync

Automatically synchronizes asset data across all devices and integrates with a cloud platform for real-time data sharing and scalability, ensuring data integrity across your entire team

Industry-Specific Templates

Pre-configured setups for construction companies, datacenters, groceries and healthcare facilities, and manufacturing businesses to start tracking immediately, supporting company-wide asset management across multiple locations or departments

Pricing & Plans

1 Month FREE TRIAL

- Add as many users as your organization needs.

- Unlimited Locations

- Unlimited Assets

Monthly Plan

- Add as many users as your organization needs.

- Unlimited Locations

- Unlimited Assets

Annual Plan

- Add as many users as your organization needs.

- Unlimited Locations

- Unlimited Assets

What our clients are saying

⭐ ⭐ ⭐ ⭐ ⭐ “We reduced asset loss by 85% and cut inventory audit time from 3 days to 3 hours. The mobile app works perfectly on our construction job sites, even without cell service.”

⭐ ⭐ ⭐ ⭐ ⭐ “We sped up the tagging process. It's a cool novelty to let the app do the typing for us. Also, it knew which data I had to collect, so all I had to do was point and click.”

⭐ ⭐ ⭐ ⭐ ⭐ “Finally, an asset tracking solution that our entire team actually uses. The barcode scanning is incredibly fast, and the real-time visibility has transformed how we manage our IT devices.”

Frequently Asked Questions

Asset tagging is the process of assigning a unique identifier to each refrigerant asset, enabling it to be tracked and managed throughout its lifecycle.

This identifier can be a physical tag, such as a barcode or RFID tag, or a digital tag, like a software asset tag.

Refrigerant asset tagging is a cornerstone of effective asset management, allowing organizations to keep track of their assets, reduce losses, and streamline maintenance and repair activities.

By implementing a robust refrigerant asset tagging system, you can ensure that every piece of equipment is accounted for, maintained properly, and utilized efficiently.

Absolutely! Our app works with any barcode or QR code format, so you can keep your current asset tags and start tracking immediately.

Bank-level encryption protects your asset information with secure cloud storage, automatic backups, and role-based access controls to protect your intellectual property and business assets.

Our mobile app works on iOS 12+ and Android 8+ smartphones and tablets. Access your asset data from any web browser on desktop computers, too.

Tag Wizard is optimized for critical operational assets that require maintenance tracking and regulatory compliance. This includes HVAC and refrigeration systems (chillers, AHUs, walk-in coolers), commercial kitchen equipment (ovens, fryers, prep tables), data center infrastructure (CRAC units, PDUs, server racks), and material handling equipment (forklifts, conveyors, dock equipment).

The system also supports IT assets, vehicle fleets, and other fixed assets using the same unified structure. If your asset has a nameplate, barcode, or can be photographed, Tag Wizard can track it.

No. Tag Wizard works with the mobile devices your team already carries. Any modern smartphone with a camera can capture asset data using our OCR technology, scan QR codes, and read barcodes. This eliminates the cost and complexity of deploying dedicated scanning hardware.

For facilities that want to use RFID tags for high-volume inventory tracking, Tag Wizard supports RFID integration—but it’s optional, not required.

Most organizations are up and running within days, not months. The process is straightforward: import your existing asset list (or build it as you go), apply QR code labels to your critical assets, train your team on the mobile app (typically 15-30 minutes), and start capturing data.

There’s no complex integration required. Tag Wizard is a web-based system that works immediately. You can start with a pilot group and expand site-by-site, or deploy across your entire operation at once.

Tag Wizard can import your existing asset records from spreadsheets, legacy systems, or other databases. We support common formats like CSV and Excel. Once imported, your historical data becomes part of the central repository, accessible alongside new records captured by your team.

You don’t lose anything—you just gain structure, accessibility, and the ability to keep that data current through workforce-powered updates.

Tag Wizard is designed to scale from small operations to large multi-site enterprises. Our pricing model adapts to your size and needs. Whether you’re managing three locations or three hundred, one technician or a hundred, the system provides the same high-integrity data and ease of use.

We offer a free plan option for small operations to get started, with transparent pricing that scales as your asset management needs grow.

Tag Wizard is purpose-built for refrigerant tracking and EPA compliance. The system automatically captures refrigerant type, charge amounts, dates, and technician information required for EPA reporting and AIM Act compliance.

Custom fields let you capture facility-specific regulatory requirements. When it’s time for an audit or compliance report, you can generate complete documentation instantly. The unified taxonomy ensures your data structure meets regulatory standards consistently across all locations.

Yes. Tag Wizard is a web-based system with role-based access control. Technicians can update service records from the field using mobile devices. Managers can view dashboards and generate reports from the office. Corporate teams can access multi-site data for compliance and strategic planning.

Everyone sees the same single source of truth, updated in real time. You control who has permission to view, edit, or delete records based on their role.

Multi-site tracking is a core strength of Tag Wizard. The system is specifically designed for organizations operating across multiple facilities, whether regional, national, or global.

You get unified visibility across all locations while maintaining site-specific details. Track asset movement between sites, compare performance across regions, and generate location-specific or fleet-wide reports as needed. Every asset has a location history showing where it’s been and where it is now.

Tag Wizard is an asset data collection and inventory management system, not a CMMS (Computerized Maintenance Management System) or service management platform.

What Tag Wizard does:

Captures and structures asset data using mobile devices (OCR, QR codes, barcodes)

Maintains an accurate, up-to-date inventory of all your physical assets across multiple sites

Enables workforce-powered assessments of asset condition through simple structured evaluations

Creates a central repository linking assets to manuals, parts lists, and training materials

Provides one portal where assessment data and inventory updates can be shared across your organization

Exports structured data to your existing systems (CMMS, digital twin platforms, service providers)

What Tag Wizard doesn’t do:

We don’t manage work orders, service tickets, or dispatch technicians

We don’t track parts inventory for maintenance or handle procurement

We don’t schedule preventive maintenance or generate maintenance plans

We don’t invoice for service or manage contractor relationships

Think of it this way: Tag Wizard ensures you know exactly what assets you have, where they are, what condition they’re in, and can share that truth with whatever systems you use to actually maintain them. We’re the data layer that feeds your CMMS, not a replacement for it.

Implementation includes initial training for your team, typically delivered via video sessions or on-site if needed. The system is intuitive enough that most users are productive within 15-30 minutes.

Ongoing support includes documentation, video tutorials, and direct access to our support team. Because Tag Wizard is designed for simplicity, most users rarely need support after the initial setup—the system just works.

Stop losing valuable assets.

Boost productivity with an asset tracking solution that actually works.

Join thousands of companies that’ve transformed their asset management with our mobile-first platform. Download our free app and start tracking in minutes. No credit card required for Starter Plan. 30-day money-back guarantee on paid plans.