How To Asset Tag Your Store in 3 Hours Instead of 3 Days?

When we started this journey nearly 20 months ago, we had two guiding principles:

- Tagging any store needed to cost less than $500, including labor, materials, and software.

- Technology needed to reduce keystrokes, and anyone could use it out of the box.

The process to start asset tagging had to be simple and accessible so that even non-specialists could begin tagging assets immediately.

Two store clerks just became our most recent Tag Wizards:

- Zero HVAC experience.

- 50+ assets tagged in 3 hours.

The asset tagging process was designed to be simple and systematic, enabling quick and accurate tagging for anyone, regardless of technical background.

Total Cost: under $300

Including labor, asset tags (physical labels designed for durability and easy identification), the Tag Wizard software, and lunch. These asset tags play a crucial role in tracking assets and supporting compliance requirements.

Let me tell you how they did it.

Despite extensive warnings over the past years, many commercial operators and HVAC contractors remain unprepared for the January 1, 2026, deadline when the EPA will prohibit the manufacture and import of HVAC & Refrigeration systems using certain high-GWP refrigerants.

The pressing question for commercial HVAC stakeholders isn’t just if you think you’re ready for the new HVAC R regulations that go into effect in 3 weeks, but whether you can demonstrate full compliance with these new EPA regulations.

Your current HVAC system, current HVAC systems, and current system will be directly impacted by the new rules, making it essential to evaluate whether you need a new system or new HVAC system to meet compliance requirements.

Installing an efficient system or energy-efficient system is crucial to meet the new standards; upgrading now can help ensure compliance and stay ahead of upcoming changes in the industry.

📌 Now is the time to start preparing for the new regulations.

Table of Contents

ToggleWhy Tagging Assets Matters Right Now?

The EPA’s January 1, 2026, deadline for HVAC and refrigeration asset tagging is weeks away. Traditional approaches take days per location with expensive specialists at $100/hour. You’re looking at months to get your portfolio compliant.

| Subsector (RACHP) | GWP / Use Restriction Date | Trigger for Label on Systems | What Must Be on the System Label at/after That Date | Extra Info Required for This Subsector | QR Code OK? |

|---|---|---|---|---|---|

| Industrial Process Refrigeration – Chillers | Jan 1, 2026: new IPR chillers must meet ≤700 GWP limits for exiting fluid ≥ –30°C. (Environmental Protection Agency) | Field-assembled chillers: at the time of first charge with the HFC/HFC blend (for new builds or conversions done after this date). (Environmental Protection Agency) | • Name/designation of HFC or blend (e.g., R-454B, R-1234yf, etc.) • Year of first charge. (Environmental Protection Agency) | Must also show the designed existing fluid temperature range on the label. (Environmental Protection Agency) | Yes. QR can replace a printed label if it carries all the required information and has adjacent text explaining the QR. (Environmental Protection Agency) |

| Industrial Process Refrigeration – systems without chillers | Jan 1, 2026: new IPR systems must meet 150/300 GWP caps depending on charge and whether it’s cascade/high-temp side. (Environmental Protection Agency) | Field-assembled systems: label at first charge after this date. (Environmental Protection Agency) | • HFC/HFC blend used • Year of first charge. (Environmental Protection Agency) | Must also include: • Charge size (exact or as “< / ≥ 200 lb”) • Designed refrigerant temperature range entering evaporator. (Environmental Protection Agency) | Yes, same QR conditions as above. |

| Cold Storage Warehouses | Jan 1, 2026: new cold storage systems/products must meet 150/300 GWP caps by charge size and cascade configuration. (Environmental Protection Agency) | Field-assembled systems: Label at first charge with compliant refrigerant. (Environmental Protection Agency) | • HFC/HFC blend • Year of first charge. (Environmental Protection Agency) | Must also include charge size (exact value or as it relates to the 200 lb threshold). (Environmental Protection Agency) | Yes, QR allowed if it fully replaces the physical label’s content + has visible explanatory text. |

| Retail Food – Remote Condensing Units | Jan 1, 2026: new remote condensing unit systems must meet 150/300 GWP caps by charge size and cascade configuration. (Federal Register) | Field-assembled systems: label at first charge (new systems or conversions after this date). (Environmental Protection Agency) | • HFC/HFC blend • Year of first charge. (Environmental Protection Agency) | Must also include charge size (exact or “< / ≥ 200 lb”). (Environmental Protection Agency) | Yes, QR can serve as the required label if it meets the formatting rules. |

| Self-Contained Automatic Commercial Ice Machines | Jan 1, 2026: small/mid-size self-contained machines must use ≤150 GWP refrigerant. (Environmental Protection Agency) | Products: Label is required on units manufactured/imported on or after this date. (Not a field-assembled system, but Tag Wizard can still scan/store it.) (Environmental Protection Agency) | • HFC/HFC blend • Year of manufacture. (Environmental Protection Agency) | Must also list: • Harvest rate (exact or as it relates to threshold) • Whether it is batch or continuous operation. (Environmental Protection Agency) | Yes, QR is acceptable in place of a full printed label under the same conditions. (Environmental Protection Agency) |

But here’s the reality: we weren’t starting from zero. We were starting in slightly negative territory.

Most facilities already had some regulations in place and incomplete records to show for it.

Refrigerated Transportation, including refrigerated trucks, buses, trains, and anything that’s portable with AC or Refrigeration and has a weight of 15 or more LBS, is supposed to be tagged/labelled.

Identifying all relevant asset types (such as chillers, remote condensing units, cold storage systems, and portable refrigeration) is critical to ensure that every valuable asset is included in the compliance process and not overlooked.

Manual spreadsheet tracking methods have proven to be time-consuming and prone to errors, making them unsuitable for meeting tight compliance deadlines.

In a very recent experience, one that motivated us to build Tag Wizard, a company I was very close to spent millions of dollars tagging assets over an 18 month period, and only found out at the very end that the details they were missing rendered the entire process useless, and they had to start over.

We knew asset tagging needed to evolve and evolve quickly, because accurate tracking is essential for regulatory compliance and operational efficiency.

Asset tagging matters for more than just compliance.

It streamlines operations and reduces risk. Every single project I worked on for decades had the wrong data, old out of date equipment specs from some archive that, in some cases, had sent me to far away places to do work on systems that were not even close to the spec, either too much refrigerant or not enough, but rarely as the quote suggested.

Creating an Asset Inventory

Asset inventory forms the foundation. You should be able to walk your facility with purpose and with the stroke of a phone camera, verify or document every physical asset: HVAC units, refrigeration systems, portable monitors, specialty tools. Network routers and kitchen equipment matter too. Nothing valuable should go unrecorded.

Capture what counts: asset type, location, serial number, maintenance history. Capturing complete asset details, including descriptions and owner data, is essential for effective asset management. Enter everything into one centralized database. This becomes your single source of truth. The upfront effort streamlines tagging and enables precise tracking.

Generate tailored tags for each asset. Use durable asset tags that can withstand harsh environments and ensure long-term identification. Affix them with confidence. Quick identification follows naturally. Reliable tracking spans the entire lifecycle. Your comprehensive inventory delivers efficient management and seamless compliance.

The foundation is set. Now it works for you. If a tag is gone or missing, find it in the system and retag it. Want to use expensive tags – great, cheap ones, that’s fine too, because our asset tagging app can read them all.

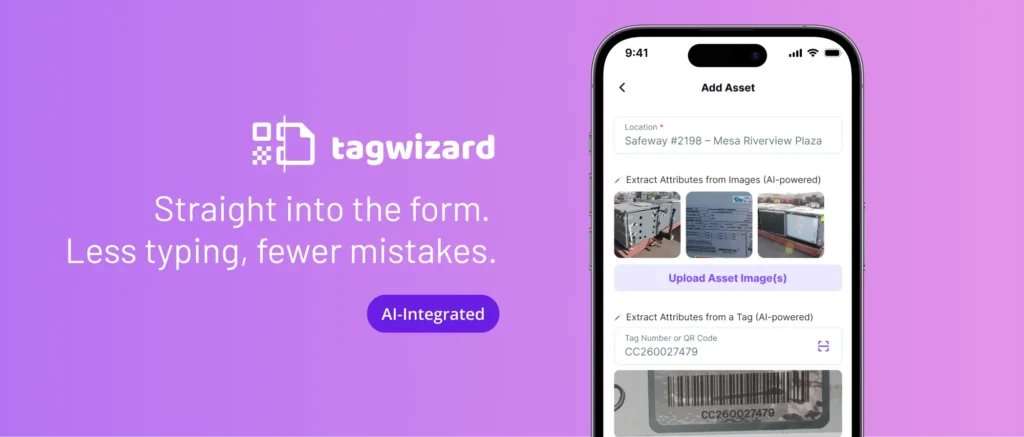

Point, Speak, Done: Three Technologies That Turn Anyone into a Tag Wizard

The Challenge

Traditional asset tagging demands HVAC specialists who know how to read nameplates, understand equipment types, and document everything correctly.

At $100/hour, sending specialists to every location makes full compliance impossible before the deadline.

What Changed

We eliminated the expertise barrier with three breakthrough technologies that make accurate data collection fast and effortless:

#1 Voice-to-Text That Actually Works

Keep your hands free to open doors and apply tags while you dictate location details, equipment condition, and maintenance notes. No typing on a phone screen in a mechanical room wearing gloves.

Real example: “Second walk-in cooler, back left corner, compressor making unusual noise.” The app writes it all down perfectly while you keep working. Accurate asset data without the keystrokes.

#2 OCR Nameplate Reading—Like X-Ray Vision for Equipment Data

Point your phone at any equipment nameplate, even worn or dirty ones. Our asset tagging app automatically extracts serial numbers, model numbers, manufacturers, capacity ratings, and refrigerant types. No squinting. No manual data entry. No mistakes.

What took 5 minutes of careful typing now takes 5 seconds.

And it’s accurate because the OCR reads directly from the manufacturer’s nameplate, no human transcription errors.

Coming soon

Automatic data fill-in that adds missing data from your Serial and model numbers. Technologies like RFID readers will further automate asset identification and data collection.

#3 Photo-Guided Capture + Smart Questions for Complete Documentation

The app shows you exactly what to photograph and automatically associates images with the correct asset. But here’s what makes it powerful: structured taxonomy and responsive questions tailored to each asset type.

Pick “Walk-in Cooler” and Tag Wizard asks the questions that matter for walk-ins. Switch to “Rooftop HVAC Unit”—different questions, exactly what EPA compliance requires. No guessing. No scrolling through 50 irrelevant fields.

Complete visual documentation for compliance audits without post-processing

For site surveys

This combination cuts documentation time from 15 minutes to under 90 seconds per asset. Show the full picture by translating pictures into asset details, which Tag Wizard uses for filling in the blanks and speeding your data capture process.

Complete visual documentation for EPA compliance audits without post-processing.

Best Practices for Asset Tagging

| Concept | Reasoning | Impact |

|---|---|---|

| Pick Tags That Can Take a Beating | Real equipment doesn’t live in a PowerPoint. It lives in: – Walk-in freezers at -10°F – Mechanical rooms at 120°F – UV light that kills most labels by year three – Rooftops, loading docks, and back alleys You need tags matched to those conditions, not just whatever was cheapest in the catalog. | Strong adhesive and the right material mean tags don’t peel, fade, or disappear just when you need them. You can build the tag to fit your budget and your goals: use metal plates where possible and when they fit the budget, and durable labels everywhere else. Tag Wizard is tag agnostic, so you can scan and track RFID, NFC, barcodes, and printed labels as often as you want. The cost doesn’t change with format; just pick the tag that meets your environmental needs, and know the data will stay usable. |

| Tag Everything. No, REALLY Everything. | We don’t punish you for being organized. Our asset tagging app is $100/location with: – Unlimited assets – Unlimited users. So stop rationing labels. If it has a serial number, a plug, or a maintenance cost, it gets a tag: – The $50 display stand: tag it. – The $10,000 compressor: definitely tag it. – Ice machines, prep tables, hand sinks, exhaust fans, back-room fridges: tag them all. When everything is tagged and documented, your asset list matches reality. | Tagging everything removes blind spots. You stop losing track of “cheap” equipment that quietly eats labor and downtime, and you stop being surprised by big-ticket failures. Unlimited assets/users means you can standardize behavior instead of managing around licensing limits. Over time, this builds a complete asset registry that supports better budgeting, fewer surprises, and cleaner maintenance planning. |

| 3. Audit Routinely—Turn It into a Hunt, Not a Hassle | “Asset audit” doesn’t have to mean clipboards and groans. Use quick inventory walks to: – Confirm assets are where they’re supposed to be. – Catch untagged or “mystery” equipment, – Keep your asset registry from going stale Make it a game: run a monthly Tag Hunt or “Easter Egg Audit.” New assets get added all the time, so gamify the process. Give a prize to the person who finds the most untagged or mis-tagged assets. | Ditching the clipboard shows your team that asset tracking is a priority, and your tools now match that priority. Location tracking for portable equipment (fans, slicers, small coolers) reduces loss and wandering assets. Mystery equipment always comes with a cost, so building a culture of “if you see it, tag it” keeps the surprises down. Asset registries go stale fast, so Tag Wizard adds little cues (like where the tag is placed) so teams can find and verify tags quickly during audits. By keeping audits visible and even a bit fun, you’re more likely to capture all assets and keep data current. |

| 4. Update in Real Time | Assets move, get serviced, and get replaced constantly. If updates live on sticky notes or in someone’s memory, your system is already out of date. With our asset tagging app, techs can: – Use voice input to add notes while standing at the unit – Use OCR and photos to capture model and serial numbers – Update location, condition, and maintenance status in seconds – Learn more about the future of owning & operating refrigeration equipment, EPA compliance, and sustainability. | Real-time updates turn Tag Wizard into a live source of truth instead of a yearly report. Everyone (maintenance, finance, operations, compliance) works from the same current information, so fewer mistakes, fewer duplicate visits, and fewer “Wait, which unit did we fix?” conversations. Fixing data when you notice a change is the easiest way to build long-term trust in your asset records. |

| 5. Standardize Across All Locations | You don’t want 10 different ways to describe the same cooler. Set one simple asset taxonomy or standard for all locations: – Same fields (location, category, manufacturer, model, serial, condition, etc.) – Same rules for what gets tagged – Same process for how to update and audit – Document it once, then train everyone to follow the same playbook. | Standardization turns a pile of local spreadsheets into a portfolio-wide asset registry you can actually use. New hires learn the system in minutes, not days. Staff can move between locations without relearning the rules. Corporate audits, insurance questions, and compliance checks become “run a report,” not “start from scratch.” Tag Wizard becomes the common language for assets across the organization. |

| 6. Invite Your Vendors to the Party | Your service partners are part of your asset story; don’t keep them in the dark. Invite key HVAC, refrigeration, and kitchen equipment vendors into Tag Wizard so they can: – See the same asset list you see – Attach service notes, photos, and recommendations directly to each tagged asset – Flag units that are inefficient, failing, or near end-of-life. Now everyone is looking at the same equipment record, not guessing from emails and old work orders. | Pulling vendors into our asset tagging app turns every service visit into a data-building opportunity. You get richer histories, better repair/replace choices, and fewer “which unit are we talking about?” phone calls. Over time, this reduces repeat truck rolls, improves capital planning, and makes your vendor relationships feel like a joint operations team instead of a ticket queue. |

| 7. Share the Results (Scoreboards Make People Care) | People work harder for things they can see. Use Tag Wizard data as a scoreboard: – Share “% of assets tagged” by location – Highlight sites with zero untagged equipment – Publish lists of “Top Found Assets” from Tag Hunts Send simple dashboards or exports to: – Store and facility managers, to drive local accountability – Maintenance leaders – to prioritize inspections and repairs – Finance and compliance – to connect assets to budget, risk, and regulatory readiness | Assets move, get serviced, and get replaced constantly. If updates live on sticky notes or in someone’s memory, your system is already out of date. With Tag Wizard, techs can: – Use voice input to add notes while standing at the unit – Use OCR and photos to capture model and serial numbers – Update location, condition, and maintenance status in seconds Learn more about the future of owning & operating refrigeration equipment, EPA compliance, and sustainability. |

The Tag Wizard Challenge: Under $300, Under 3 Hours, Beyond Scope

Two store clerks (zero HVAC experience) became Tag Wizards in under 3 hours. They didn’t know what a TXV was.

They couldn’t identify a compressor nameplate before we started. Along the way, we also discussed the importance of understanding HFCs in fire suppression and their environmental impact.

Voice, OCR, and photo guidance made them experts instantly.

📌 Asset tagging matters for more than just compliance.

It streamlines operations and reduces risk.

How We Got Here: A Mid-Course Pivot That Made Tag Wizard Better

Original intent

Build an easy-to-use HVAC and refrigeration tagging app for EPA compliance, minimum refrigerant tracking.

Summer 2025

Someone we really respected had a project and was willing to trial the app, but they were responsible for tagging and identifying assets throughout the store, and they wanted Tag Wizard to do more. Point-of-sale systems. Computer networks. Vertical lift equipment. Delis, cars, trucks, compactors—all of it.

We had to double down. I’m proud (and excited) to say our team delivered in 3 months.

We expanded to 31 asset categories by staying focused on our core commitments and using techniques that have worked for us: building a solid asset taxonomy, conducting user interviews, and, most importantly, forcing our own team to use the app. I personally did dozens of store and location audits to make sure we were on the right track.

The pattern we discovered

High-value equipment and low-value equipment both benefit from the same streamlined tagging approach. Tags are placed on each asset, then scanned and tracked in real-time, streamlining compliance and inventory management across all equipment types.

To ensure comprehensive asset management, it’s important to tag both fixed assets, like HVAC units or refrigeration systems, and movable assets, such as portable monitors or carts, since each requires different tracking and maintenance strategies.

People were actually auditing us as we tagged a store, then we realized, if it’s easy to capture high-value assets, like HVAC/R and Point of Sale Systems, then why not simpler things like Displays or loading docks – they don’t all need to be tagged, maybe just identified.

Our asset tagging app works great for that, too.

As we went through our pilot phase, managers would come through and use the app to verify our data, and it was perfect for that was an eye opener because it showed us a new use case, where tagging assets if it were easy would be routine and common if it were easy to do it and affordable.

📌 “This is more than just a one-time thing; the pilot beta test tag wizards were using it to verify store details when doing a store walk-through.”

What Our Tag Wizards Actually Delivered

Original Scope

HVAC and refrigeration only (EPA compliance minimum)

Actual Deliverables

Walk-in coolers, reach-in cases, rooftop HVAC units, compressors, PLUS ice machines, food prep equipment, meat slicers, kitchen appliances, network routers, elevators, point-of-sale systems—essentially everything was taggable.

Why did they keep going?

Because becoming a Tag Wizard is addictive. Once they mastered refrigeration assets (the EPA requirement), they wanted to tag everything else. The $100/location software covers unlimited assets and unlimited people—so why not keep going?

That’s what we call our users

“Taggers” when they’re learning the basics. “Tag Wizards” when they’ve mastered it. These two became Tag Wizards in the first hour.

On time. Under budget. Beyond scope. We set out to prove tagging could cost under $500. We did it for under $300. That’s project delivery excellence.

What Does an Asset Tagging System Actually Cost?

Most enterprise asset management platforms charge per-user with complex pricing tiers. If you have 50 stores, that can easily hit $50,000 just for software.

📌 An asset management system is essential for organizations looking to manage assets efficiently and cost-effectively, but high software costs can be a barrier.

Tag Wizard is different, by design.

We built this based on 32 years of hands-on facilities and property management experience.

We don’t have 10 people doing all the work, and we won’t any time soon, because we’re not a software company trying to understand your world; we’ve lived it.

We know what it’s like tagging equipment in a -10°F walk-in freezer or documenting HVAC systems in a mechanical room with no cell signal.

Dirty hands, fat fingers, and screens with 20 cracks, that’s where we live, that’s been our life for longer than I can remember.

Our pricing reflects our principles:

- Cost: $100 per location (but even this is limited)

- No per-user fees: Tag unlimited assets with unlimited staff

- No hidden charges: What you see is what you pay

- Current offer: The App is free right now. First 1,000 locations get two years at $100/location

The math

50-store grocery chain = $5,000 for software (not $50,000). The rest of your budget goes toward actually getting compliant.

Your goal

Get assets tagged before the EPA deadline.

Our goal

Make software the smallest part of that expense, about 20% of your total cost. Labor is the other 80%, which is why we built tools that let anyone become a Tagger. This way, you can manage assets effectively without excessive asset management system costs.

On Time, Under Budget, Beyond Scope

We set a project goal: complete a grocery store asset tagging project for under $500 total cost, meeting EPA compliance requirements using store staff. We delivered ahead of schedule.

But here’s the project delivery excellence part: we didn’t just meet the minimum scope—we exceeded it dramatically. This commitment to going beyond expectations extends to our approach to compliance, where using innovative solutions like Tag Wizard ensures our clients are always ahead in regulatory readiness.

Original Scope

HVAC and refrigeration equipment only (the EPA compliance minimum for refrigerant tracking).

Actual Deliverables

They went far beyond scope, documenting walk-in coolers, reach-in cases, rooftop HVAC units, compressors, plus ice machines, food prep equipment, commercial meat slicers, kitchen appliances, network routers, and elevators—everything that needed asset tracking.

The new process allowed the organization to tag and track assets efficiently, ensuring nothing was missed.

They kept tagging because Tag Wizard made the process simple.

The $100/location software cost covered unlimited asset tagging, making the expanded inventory practically free.

Modern tracking systems, such as RFID and barcode solutions, are key to maintaining accurate asset records and compliance.

Why Can’t My CMMS Track Equipment I Haven’t Tagged?

If your HVAC and refrigeration assets aren’t documented by January 1, 2026, your CMMS becomes useless for compliance planning.

The problem

Your CMMS and compliance software can only track assets it knows about. Missing equipment means:

- Can’t accurately track refrigerant

- Can’t schedule required maintenance

- Can’t plan for future capital investments

- Can’t demonstrate EPA compliance

- Prevents effective maintenance management and disrupts maintenance schedules

Reality check

Across 600+ commercial sites we’ve worked with, fewer than 5% were adequately prepared for EPA refrigerant tracking requirements. Most had missing serial numbers, incomplete records, or equipment that existed physically but not in their systems.

Complete asset tagging ensures maintenance records are accurate and up to date, supporting reliable maintenance management and compliance.

The solution

Tag Wizard makes it possible to achieve full EPA compliance across your entire portfolio in weeks, not months.

What Makes Tag Wizard Different from Other Tagging & Software?

We built this based on 32 years of hands-on facilities experience—not as a software company trying to understand facilities management. We know what it’s like tagging equipment in a walk-in freezer at -10°F or documenting HVAC systems in a mechanical room with no cell signal. An effective asset tagging system is crucial for accurate reporting and compliance.

Tag-Agnostic

Use QR codes, NFC tags, barcodes, or just photos. Your existing tags work with our platform. We don’t lock you into proprietary hardware.

Asset Data, Not Big Data

We’re not selling analytics dashboards or “strategic planning modules.” Just accurate asset records for CMMS integration, refrigerant tracking, and maintenance scheduling.

Built for Field Conditions

Voice input works when you’re wearing gloves. OCR reads worn nameplates. The app functions offline when the cell signal drops.

With reliable asset data, you can make data-driven decisions for maintenance and investment.

More Cool Features That Make You a Tag Wizard

Real-Time Duplicate Detection

Tag a compressor serial number that the app already knows? Instant alert. No duplicate records pollute your CMMS. Your database stays clean from day one.

31 Asset Categories

Beyond EPA requirements (HVAC, refrigeration), tag everything: kitchen equipment, meat slicers, cash registers, fire extinguishers, routers, elevators. Complete facility inventory at the same $100/location cost. It’s important to select appropriate asset labels for each asset type, considering conditions and security needs, to ensure reliable tracking and compliance.

Unit Flexibility

Your German contractor uses centimeters. Your US team uses inches. Tag Wizard adapts. Everyone works in their preferred units.

Auto-Generated Reports

For site surveys, Tag Wizard cuts documentation time from 15 minutes to 90 seconds. Visual reports that customers actually understand.

Soon…

🔜 Offline Mode

No cell signal in the mechanical room? Keep tagging.

Everything syncs automatically when you’re back online.

Tracking assets and collecting usage data enables you to optimize maintenance and compliance software, improve resource allocation, and make informed decisions about your assets.

Supporting Your Workflows (The Stuff That Actually Matters Daily)

Unit Preferences: Stop the Confusion

Your German contractor measures in centimeters. Your US team uses inches. Your Canadian partner wants feet. Instead of everyone doing mental math and making mistakes, Tag Wizard lets each person work in their preferred units. Problem solved.

The AKO Partnership: Free Is Good

Buy an AKO leak detector, certified to meet UL 60335-2-40 safety requirements, and get six months of Tag Wizard FREE.

More importantly, all your device registration and calibration data lives in one place.

When your leak detector needs recalibration or you need proof of purchase for warranty claims, it’s already documented. No hunting for paperwork.

Common Challenges (And How to Actually Handle Them)

What if We Don’t Have a Budget for Expensive Tags?

Good news: you don’t need expensive tags. Adhesive labels work fine for most indoor equipment. Metal plates for harsh environments, if you need them. Tag Wizard works with whatever you can afford—even just photos of nameplates with no physical tags at all.

What if we are worried our Team Won’t keep the Database Updated?

This is why we built voice input and OCR. Updates happen while you’re standing in front of the equipment—no going back to a desk, no data entry later. Make it a 5-second habit instead of a 15-minute task, and people actually do it.

Also: try the audit game. Free Starbucks or a slice of Pizza for whoever finds equipment that’s not in the system yet. Suddenly, your team is actively looking instead of avoiding updates.

What if we Need This Data in Our Other Systems

Tag Wizard isn’t trying to replace your CMMS or service management software. It feeds them accurate data so they can actually work. Get your assets documented first, then integrate with whatever systems you already use.

Making It Last (Not Just Getting Started)

We don’t have a budget. Can we phase it in?

Don’t try to tag every location in one weekend. Start with high-value equipment and EPA-required assets. Build momentum. Let your Tag Wizards get confident before scaling up.

Who should I add to my Tag Wizard subscription?

Short answer – everyone or anyone you think can help, you add and remove people as you need to, but one thing we do suggest: Someone needs to own this. Maybe it’s the facilities manager. Maybe it’s a service coordinator. Doesn’t matter who, but someone needs to be the person who checks that new equipment gets tagged, and old equipment gets retired from the system.

Train people once properly instead of poorly three times.

Audits Don’t Have to Suck

Schedule routine checks—monthly or quarterly, depending on how fast things change. Make it quick: verify 20 assets, spot-check a few locations, look for anything obviously wrong.

Real-time tracking means issues surface quickly instead of hiding until the annual nightmare audit. Fix problems when they’re small.

What’s Under the Hood?

We standardized date formats to YYYY/MM/DD, optimized the database so large datasets load faster, and improved API response times.

The app feels snappier, especially when you’re working through a long list of assets. Continuous updates to tagging systems ensure they remain effective and user-friendly.

As we consider how technology improvements can align with greater environmental responsibility, it’s worth understanding the importance of Earth Day for a sustainable future.

Coming Next

Automatic data enrichment. Tag Wizard will automatically add missing details, link to equipment manuals, and provide reliable equipment records without manual lookup, to help you ensure readiness for GHG emissions reporting and compliance.

In conclusion, asset tagging systems are essential for maintaining reliable records and supporting ongoing improvements in asset management.

So if you’re wondering: how do you asset tag your store in 3 hours instead of 3 days?

Then start here, email me, , and share your details, email, name, and size of the organization, because we are already 72% of the way to the 1000 locations.

There are no strings attached; I don’t need a PO or a long-term commitment, just your interest works. We won’t even start charging for the app until the end of Q1 2026.

You can document your entire portfolio before the January deadline without breaking the bank.

Tagging high-value equipment is essential to prevent loss, ensure compliance, and maintain operational efficiency. Using technologies like passive RFID tags and active RFID tags can further enhance asset tracking capabilities, especially for large or complex operations.

📌 We are actively working with grocery chains, restaurant groups, Data Centers, and cold storage operators, and understand the January 1 deadline pressure.

The App is Free Right Now.

Your Offer

The first 1,000 locations get two years of discounted pricing at $100 per location. No user fees. No per-seat charges. For industry insights and updates, check out our HVAC/R Blog – Carbon Connector.

The Math

If you run a 50-store grocery chain, that’s $5,000 for software, not $50,000. The rest goes toward getting your portfolio compliant.

The Result

Complete, accurate asset inventories in time to meet EPA requirements and maximize the value of your existing CMMS and compliance tools.

Ready to become a Tag Wizard?

Download Tag Wizard on the App Store and Google Play or reach out directly: