How to Calculate your Refrigerant Leak Rates like a Pro

Are you wondering how to properly calculate your refrigerant leak rate in accordance with EPA 608?

Accurately determining your refrigerant leak rate is essential for compliance, operational efficiency, and avoiding unnecessary costs.

Knowing how much your HVAC/R equipment, such as an air conditioning system or refrigeration equipment, is leaking is crucial to comply with these regulatory requirements and operate within budget.

Accurate calculations when determining leak rates help ensure you meet environmental standards and maintain system performance.

Proper installation quality can significantly influence refrigerant leak rates and long-term system reliability.

Do you want to calculate your Refrigerant Leak Rates like a Pro?

Table of Contents

ToggleAre You Unsure of Your Refrigerant Leak Rate Calculations?

Indeed, any uncertainty in estimating your refrigerant leak rate calculations increases your risk and leaves gaps in your maintenance process.

With changes to the EPA 608 leak repair requirements taking effect very soon, you just can’t afford to be unsure…

This post is going to help you understand how to properly estimate and calculate your refrigerant leak rates, so you can get consistent outcomes across your building portfolio.

Keep in mind that leak rates and their associated costs can vary depending on the location of each facility, making it important to assess each site individually.

In fact, by the end, you will be able to test your knowledge of refrigerant leak rate calculations with our refrigerant leak rate calculator form and guide.

Let’s get started.

U.S. EPA Recognizes Two Methods for Calculating Refrigerant Leak Rate

First things first, the U.S. EPA, in its National Refrigerant Management Program, otherwise known as Section 608, calls out two methods for calculating your refrigerant leak rate: the (1) Annualizing Method and the (2) Rolling Average Method.

Both methods use specific formulas prescribed by the EPA to calculate refrigerant leak rates:

→ Discover our HVAC/R Knowledge Hub

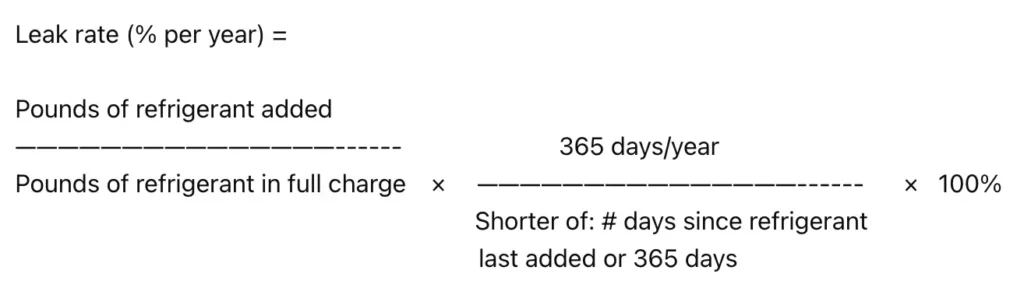

Annualizing Method

First things first, the U.S. EPA in its National Refrigerant Management Program, otherwise known as Section 608, calls out two methods for calculating your refrigerant leak rate: the (1) Annualizing Method and the (2) Rolling Average Method. Both methods use specific formulas prescribed by the EPA to calculate refrigerant leak rates:

This method is “future-oriented” and “considers the amount of time since the last refrigerant addition and then scales that up to provide a leak rate that projects the amount lost over a whole year if not fixed” (81 FR 82272).

The leak rate is calculated using a formula that incorporates the amount of refrigerant added and the total refrigerant charge of the system.

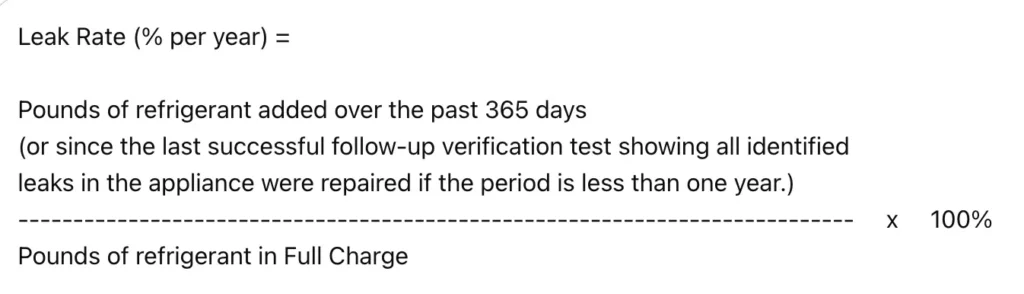

Rolling Average Method

This is a retrospective approach to refrigerant leak rates and “accounts for all refrigerant additions over the past 365 days or since the last successful follow-up verification test showing that all identified leaks were successfully repaired (if less than 365 days)” (81 FR 82272).

This method is leak-rate-based and requires accurate record keeping of refrigerant added over time.

The formulas used for calculating leak rates may vary depending on equipment type and the specific components of the system, such as compressors, condensers, evaporators, coils, valves, seals (including rubber seals), and piping.

Unit conversions may be necessary to ensure accurate calculations, especially when dealing with different measurement systems.

After repairs, testing, and verification are important steps to ensure the calculated leak rate is accurate and that all leaks have been properly addressed. Leak testing, including pressure testing, is essential to identify and repair leaks in HVAC equipment such as compressors, coils, and evaporators.

For example, using the Annualizing Method, if 10 pounds of refrigerant were added to a system with a total refrigerant charge of 100 pounds over a 90-day period, the leak rate would be calculated as:

Leak Rate (%) = (10 lbs / 100 lbs) × (365 / 90) × 100 = 40.6%.

📌 Refrigerant leakage rate is typically measured as a percentage of the total refrigerant charge, and accurate refrigerant levels must be determined for precise calculations. This example demonstrates how the formula is applied in practice for compliance and maintenance purposes.

Monitoring refrigerant levels and performing regular leak testing on all major HVAC equipment components, including compressors and valves, is essential for compliance and optimal system performance.

This is the foundation of EPA 608’s leak repair requirements… If you’re not careful and you get your refrigerant leak rate calculation wrong, everything else from there will go downhill…

So, it’s important that you get down the basics and the interworkings of these two methods.

Do you want to calculate your Refrigerant Leak Rates like a Pro?

5 Things to Keep in Mind About the EPA’s Refrigerant Leak Rate Calculations

Now that we’ve shown you the two methods you need to properly calculate your refrigerant leak rates, here are a few things you need to keep in mind about these refrigerant leak rate calculations (that most people forget):

- They are NOT per-occurrence leak rates.

- They look at a period of 365 days.

- They are not just based on weight.

- You need to pick a method and stick with it.

In fact, it states, “the same method must be used for all appliances subject to the leak repair requirements located at an operating facility” (40 CFR Part 82 Subpart F).

- If you exceed the maximum allowable refrigerant leak rate for your appliance, you are out of compliance.

Additionally, there are some things to keep in mind:

- You must repair the leak within 30 days. Timely repairs and documentation of test results are required to demonstrate compliance.

- Maintaining accurate repair records and proper record-keeping is essential for compliance with EPA regulations. This includes documenting repairs, test results, and leak rates.

- Starting on Jan. 1, 2019:

- Per the EPA 608 Update, if you surpass the maximum allowable refrigerant leak rate, you are also subject to mandatory leak inspection requirements. More on that here.

- There is a new reporting requirement for chronically leaking appliances, which gives you all the more reason to ensure your refrigerant leak rates are within compliance.

- Failing to comply with leak rate requirements can result in significant cost implications, including fines, repair expenses, and potential inventory losses.

Environmental Impact of Refrigerant Leaks

Refrigerant leaks damage more than profits. They damage the planet. Refrigerant leaks harm the environment by affecting air quality and contributing to ozone depletion.

CFCs and HFCs escape into our atmosphere, depleting ozone and accelerating climate change.

The ozone layer shields Earth from harmful radiation. Its erosion creates health risks and environmental consequences. Many refrigerants carry high global warming potential. Small leaks trap significant heat, intensifying global warming.

The Montreal Protocol, an international treaty, was established to address these issues by phasing out ozone-depleting substances and reducing HFC emissions.

Calculating refrigerant leaks transcends regulatory compliance. It reflects planetary responsibility. Accurate tracking and management prevent ozone depletion and reduce greenhouse gas release.

Maintaining proper refrigerant charge is essential for effective cooling and air conditioning system performance, and air-related issues such as leaks or water intrusions can further exacerbate environmental harm.

📌 Every leak you identify, calculate, and repair in HVAC systems creates real environmental protection.

The impact matters. Future generations depend on it.

The True Cost of Refrigerant Leaks

The prevailing industry narrative surrounding refrigerant leaks systematically obscures a fundamental economic reality.

When leaks persist undetected, they constitute nothing less than a systemic assault on operational efficiency: a truth the HVAC establishment finds profoundly uncomfortable.

The data reveals an inescapable conclusion: even marginal refrigerant loss precipitates a cascade of inefficiencies that exponentially compound operational expenditure.

Your equipment labors under this burden, driving energy consumption to precarious levels while accelerating component degradation.

📌 The inevitable consequence?

Utility costs spiral upward, service interventions multiply, and equipment replacement cycles contract dramatically.

Yet the industry’s fixation on immediate financial metrics represents a fundamentally flawed assessment of refrigerant leak consequences.

The uncomfortable truth demands acknowledgment: every leak constitutes an environmental transgression of significant magnitude. These chemical releases directly accelerate atmospheric degradation through ozone depletion and climate acceleration.

The global warming potential of these refrigerants renders even seemingly insignificant leaks environmentally catastrophic, trapping atmospheric heat for years.

This environmental culpability transforms accurate refrigerant leak rate calculation from mere regulatory compliance into an unavoidable moral and technical imperative.

The forensic evidence demands a definitive conclusion: calculating refrigerant leak rates represents not an operational suggestion, but a systemic mandate for responsible equipment management.

This analytical rigor provides the intelligence necessary to identify problematic installations, prioritize interventions, and maintain optimal refrigerant charges.

The path forward requires unwavering commitment to this proactive methodology—anything less constitutes professional negligence.

Organizations that embrace this analytical discipline simultaneously protect their operational integrity, equipment longevity, and environmental accountability.

📌 The choice remains stark

Implement rigorous leak rate management, or accept the inevitable consequences of systemic failure.

Your Refrigerant Leak Rate Calculation Form and Guide

We’ve walked you through EPA’s two refrigerant leak calculations, and we’ve also told you 8 things to keep in mind about them.

Now, you probably want to check and see if you’re doing it right. Right? Well, you’re in luck because we’ve created a free refrigerant leak rate calculation form and guide.

(No more guessing: Learn how to easily calculate your refrigerant leaks using the Annualizing or Rolling Average Method!)

Grab the download now, and check your refrigerant leak rate calculations at your own convenience.

We’ve made it that simple for you.