Reducing the risk of Legionella contamination in your refrigeration systems

Learn how to minimize Legionella contamination in building air conditioning and refrigeration systems that rely on water towers and water-based cooling.

Table of Contents

ToggleWhat is Legionella?

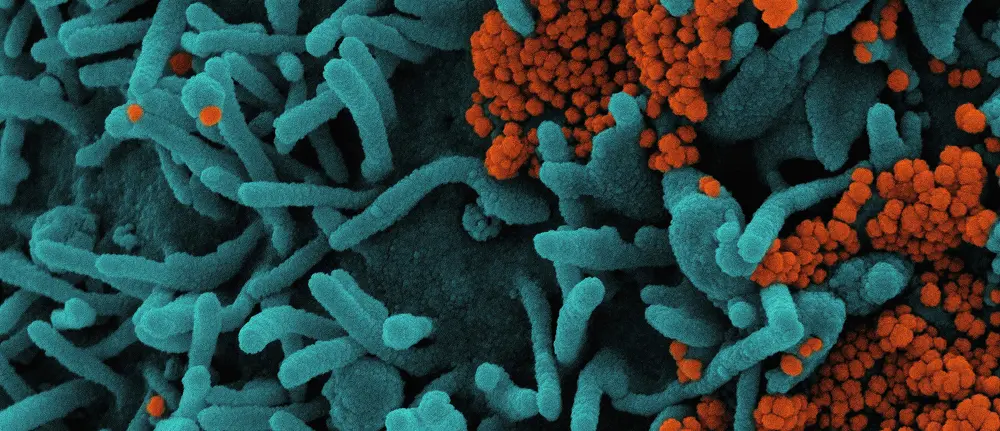

Legionella is a type of bacteria that poses a significant risk in building water systems, particularly those associated with air conditioning and refrigeration systems.

This microorganism is most notorious for causing Legionnaires’ disease, a severe and sometimes fatal form of pneumonia.

Legionella thrives in environments where water is present, particularly in cooling towers, evaporative condensers, and complex plumbing systems.

The building water system is a critical focal point for managing Legionella risk, as its design, maintenance, and operation directly impact the potential for bacterial growth and transmission.

These systems can inadvertently create ideal conditions for Legionella growth—namely, warm water temperatures and stagnant water. When water is allowed to sit without proper circulation or treatment, the risk of bacterial proliferation increases dramatically.

Understanding how Legionella exploits these vulnerabilities is the first step in preventing outbreaks and safeguarding both building occupants and the broader public from the risks associated with Legionnaires’ disease.

Effective control and prevention strategies, including water management programs and regular system maintenance, are crucial for reducing the risk of Legionella proliferation.

📌 Addressing Legionella in building water systems is a crucial aspect of disease control and public health protection.

The Pathogen and the Outbreak

Legionella bacteria are naturally present in freshwater sources, but they become a public health concern when they enter man-made water systems. In facilities with cooling towers, evaporative condensers, and other water-based HVAC components, Legionella can multiply rapidly under the right conditions.

The primary route of transmission is through inhalation of tiny water droplets (known as aerosols) that are contaminated with the bacteria.

These droplets can be generated by cooling towers and other water systems that generate aerosols, making them a key focus for disease prevention. Inhalation of these aerosols can cause Legionnaires’ disease.

Legionella exposure primarily occurs through inhalation of aerosolized water droplets from sources such as showers and cooling towers.

The American Industrial Hygiene Association strongly recommends that building owners and facility managers implement regular testing and maintenance protocols for all water systems to ensure optimal performance and safety.

By ensuring that cooling towers and evaporative condensers are correctly maintained and routinely monitored, the risk of Legionella growth and subsequent outbreaks can be significantly reduced.

Contracting Legionella disease is a serious risk when contaminated water systems are not adequately managed.

Preventing the accumulation of biofilm, controlling water temperature, and promptly addressing any signs of contaminated water are all essential steps in maintaining the safety and compliance of these systems.

Understanding Legionella Contamination

Legionella contamination is a complex issue that can affect a wide range of water systems, including cooling towers, evaporative condensers, building plumbing networks, and potable water systems.

The risk of contamination is exceptionally high in systems where water stagnates, temperatures remain within the optimal range for bacterial growth, or maintenance is inconsistent.

Factors such as the presence of biofilm, dead legs (sections of piping where water does not circulate), and inadequate water flow can all support Legionella growth and make control efforts more challenging. Certain conditions, such as water stagnation and improper temperature control, can facilitate the growth of Legionella.

To effectively control Legionella, it is crucial to implement comprehensive water management programs that address these risk factors.

Such programs should include regular monitoring for Legionella contamination, routine cleaning and disinfection, and strategies to maintain consistent water flow throughout the system, as well as specific measures to prevent Legionella growth.

By proactively managing these elements, facility managers can significantly reduce the likelihood of Legionella outbreaks and ensure that their cooling towers, evaporative condensers, potable water, and plumbing systems are properly maintained, safe, and compliant.

🦠 The bacterium thrives between 77°F and 113°F (25°C–45°C), embedding itself in biofilms and multiplying inside free-living protozoa, which protect it from disinfection. Once aerosolized through mist, drift, or spray, inhalation can cause Legionnaires’ disease, a severe and potentially fatal form of pneumonia.

The incubation period ranges from 2 to 10 days. Early symptoms often resemble seasonal flu: fever, chills, cough, muscle aches, and shortness of breath.

Without timely antibiotic therapy, the infection can progress to respiratory failure, septic shock, and multi-organ dysfunction, with mortality rates ranging from 5–30% depending on patient health and outbreak response speed.

In contrast, cold water is less conducive to Legionella growth and is considered safer for uses such as handwashing and dishwashing, helping to minimize exposure and prevent Legionnaires’ disease.

The July 2025 Harlem outbreak is the latest in a troubling pattern. NYC Health Department confirmed multiple cases linked to contaminated cooling towers in Upper Manhattan, echoing the 2015 South Bronx outbreak that sickened more than 120 people and killed 12.

In 2015, then-Mayor Bill de Blasio described the outbreak as “a wake-up call” and signed the city’s first comprehensive cooling tower law.

The New York Times reported that in the days following, “city agencies… scrambled to locate, inspect and disinfect thousands of towers, pushing crews to their physical limits.”

As Facilities Dive noted in covering the Harlem event, “facility managers are once again on the frontlines — responsible for both immediate remediation and long-term prevention in a city with the most aggressive cooling tower regulations in the nation.”

Outbreak History: 2015–2025 in Perspective

Globally, between 2015 and 2025, major outbreaks have occurred in Melbourne, Sydney, Quebec City, Toronto, and Dubai, with dozens of fatalities.

The NIH review you provided estimates that 10–15% of reported outbreaks worldwide are linked to cooling tower systems, and most were preventable with proper maintenance.

Air conditioning engineers play a critical role in implementing and overseeing these maintenance protocols to reduce the risk of Legionella contamination.

How Refrigerant Leaks Can Elevate Legionella Risk

It’s well established that water temperature and stagnation are critical factors in the growth of Legionella. Refrigerant leaks — particularly in systems using water-cooled chillers or evaporative condensers — can directly influence both. For water-cooled chillers, it is important to sample and monitor cooled water just before it enters the cooling tower to accurately assess bacterial levels and optimize chemical dosing for water treatment:

Reduced cooling efficiency

A leaking system has to work harder, sometimes failing to maintain setpoint temperatures in condenser water loops. This can keep water within the “Legionella growth zone” for more extended periods.

Extended stagnation

Strained systems may cycle less efficiently, leading to uneven water movement and dead zones where biofilms thrive.

Deferred maintenance

When operators are preoccupied with leak troubleshooting or unplanned repairs, water treatment checks may slip, giving Legionella a foothold.

Deferred maintenance can also lead to increased microbial growth within filters and other system components, thereby further elevating the risk of Legionella contamination.

This is why early leak detection, such as AKO’s high-sensitivity refrigerant monitors, is not only an energy and compliance measure but also an indirect public health safeguard.

By keeping systems in peak thermodynamic performance, operators help deny Legionella the conditions it needs to multiply.

→ Read About Refrigerant Leak Detection as a Service

NYC’s Regulatory Framework: The Toughest in the Country

Following the 2015 South Bronx outbreak, New York City passed Local Law 77 and established Chapter 8 of Title 24 of the Rules of the City of New York, requiring:

- Cooling tower registration with the NYC Department of Buildings.

- Quarterly inspections and maintenance logs.

- Disinfection and cleaning at least twice a year, or immediately after shutdowns/outbreaks.

- Water quality monitoring for Legionella and other bacteria, with lab reports kept for a minimum of three years.

- Immediate reporting of test results exceeding 1,000 CFU/mL, followed by disinfection within 24 hours.

A risk assessment is typically conducted to identify hazards, which then informs the development of maintenance schedules and testing intervals.

The city also mandates chemical treatment (biocides) and physical cleaning to disrupt biofilms — the stronghold from which Legionella can repeatedly seed the water system.

✔ Protect your facilities and the environment from refrigerant leaks.

Public Health vs. Climate Change: The Duality of Performance-Based Laws

Air-conditioning systems that keep New York—and every other city—livable during heat waves are governed by a web of federal, state, and local rules. Yet even the most rigid statutes are ultimately performance-based: what matters is how the system behaves in the field.

That’s why you need performance planning, instrumentation, and software to manage them. Proper maintenance of the air handling system is also crucial, as it helps prevent the spread of Legionella bacteria by addressing potential contamination sources and ensuring routine inspections.

In New York City, Local Law 77 and Local Law 97 are two sides of the same regulatory coin—both demand measurable outcomes but tackle different risks with different levers.

LL77 targets a public-health hazard (Legionella) through registration, routine sampling, swift disinfection, and documentation.

LL97 targets climate risk through emissions limits, reporting, and penalties. Together, they require an operations program that can prove results, not just check boxes.

Local Law 77: The Rigid Performance of Public Health

Enacted in 2015, Local Law 77 is a direct response to the immediate and severe public health threat of Legionnaires’ disease. Its primary goal is the performance metric of zero preventable outbreaks.

To achieve this, the law is intentionally rigid and prescriptive, leaving no room for a flexible approach to maintenance.

The law mandates a series of non-negotiable actions for owners of cooling towers, evaporative condensers, and fluid coolers:

Mandatory Inspections and Testing

All towers must be inspected and tested for Legionella every 90 days while in use.

Strict Remediation

Specific actions and reporting timelines are triggered by microbial levels, with immediate disinfection required for levels over 1,000 CFU/mL.

Written Plan

A detailed maintenance program and plan (MPP) must be developed under ASHRAE Standard 188.

This rigidity is necessary because a single point of failure (a missed inspection, a delayed disinfection) can have fatal consequences in a dense urban environment. The law prioritizes a fail-safe process to guarantee a life-or-death performance outcome.

Local Law 97: The Flexible Performance of Climate Change

In contrast, Local Law 97 is a flexible, performance-based law designed to achieve a long-term goal: reduced carbon emissions from large buildings. The law sets progressively stricter carbon caps over time, but it does not dictate how building owners must meet them.

The law focuses on the outcome (reduced carbon emissions) rather than the specific method, allowing building owners to choose from various strategies, such as:

- Upgrading to more efficient HVAC systems.

- Purchasing renewable energy credits to offset emissions.

- Investing in on-site solar or other distributed energy resources.

This flexible approach encourages innovation and allows building owners to choose the most cost-effective path to compliance. Failure to meet the emissions cap, however, results in significant penalties.

In essence, while both laws are performance-driven, the difference in their rigidity reflects the severity and urgency of the risks they address.

LL77 requires absolute compliance with a proven process to prevent immediate harm, while LL97 permits a flexible approach to achieve a long-term environmental goal.

Lessons from the Field: What Works and What Doesn’t

According to a 2017 NIH/PMC case study on NYC’s 2015 South Bronx Legionnaires’ outbreak (J Public Health Management & Practice), the maintenance takeaways are very explicit.

Here’s a thorough distillation of what the paper says you should be doing, with short quotes from the article.

Analyzing system data and maintenance history can help determine the optimal cleaning frequency, ensuring that cleaning intervals are sufficient to prevent the buildup of solids and bacterial growth.

It is also important to protect and maintain the cooling tower basin, as shielding the basin from sunlight and deterioration helps prevent conditions that support the growth of Legionella.

What the NIH case study recommends for maintenance (thoroughly)

Put a written, ASHRAE-188–aligned maintenance plan in place

The paper describes NYC’s post-outbreak requirement that owners “develop a maintenance plan for cooling towers that is in accordance with ASHRAE Standard 188” (the national Legionellosis risk-management benchmark).

Why this matters

ASHRAE 188 forces you to survey your systems, define control limits for temperature/biocide, specify monitoring, corrective actions, and verification—so maintenance isn’t ad hoc.

These plans should meet or exceed the minimum risk management requirements established by industry standards to ensure comprehensive control of Legionella.

Register, certify, and maintain traceability.

After 2015, “Local Law 77 sets stipulations for cooling tower registration and certification and imposes maintenance, inspection, and Legionella testing requirements” citywide.

Why this matters

A registry and annual certification create accountability and an auditable record of maintenance and testing.

Inspect and test on a fixed cadence—don’t let intervals slip

NYC’s rule (as summarized in the paper): cooling towers must be “tested for Legionella every 90 days when the cooling tower is in use and within 15 days prior to the initial use during any year.”

Why this matters

90-day Legionella cultures + pre-season testing catch problems early; skipping or stretching intervals is a common pathway to outbreaks.

Follow explicit routine maintenance tasks and threshold-based remediation

The Rules “specify explicit maintenance activities that must be performed routinely and the remediation steps to be taken if routine Legionella testing… reveal certain thresholds.”

Why this matters

Your plan must clearly outline what to do when results exceed action levels (clean, disinfect, re-test, and verify return to control).

Use acceptable laboratory methods and keep records

The rules “establish acceptable methods for laboratory testing of environmental samples, as well as cleaning and disinfection of cooling towers.”

Why this matters

Consistent, validated methods reduce false reassurance (e.g., PCR positives require culture confirmation during investigations); documentation protects occupants and operators.

Disinfect swiftly when risk indicators are present—don’t wait for a crisis

During the 2015 response, the Health Commissioner “ordered all cooling towers… that had not been disinfected within the past 30 days to be evaluated… and undergo disinfection within the next 2 weeks.”

Why this matters

This codifies a bias for action, evaluation, and disinfecting promptly when systems are overdue or results are trending in the wrong direction.

Expect enforcement (and design your program so you never need it)

The rules include “an enforcement mechanism in the form of fines” for failing to register, to submit annual certification, or for failing unannounced inspections.

Why this matters

Maintenance isn’t optional; your plan must be practical enough to execute on a weekly, monthly, quarterly, and annual basis.

Build data systems and team capabilities around environmental sampling

The paper stresses that ecological data management and trained personnel were early bottlenecks; DOHMH implemented train-the-trainer field sampling and new workflows to manage environmental results at speed.

Why this matters

Maintenance includes people and data. Train techs to sample correctly; organize data so positive trends trigger immediate, documented corrective actions.

Make the registry useful for risk-based maintenance improvements.

The authors note that analyzing the registry will help identify tower characteristics linked to higher risk so officials can “suggest modifications to… maintenance plans to prevent disease more effectively.”

Why this matters

Treat your history (and the city’s) as a feedback loop—use trends to upgrade maintenance frequency, chemistry, or hardware (e.g., drift eliminators).

What this means operationally (Actionable Checklist)

✔ Write & own an ASHRAE-188 maintenance plan

(surveys, control limits, monitoring map, corrective actions, verification).

✔ Register & certify towers

Keep 3+ years of logs ready for unannounced inspections.

✔ Test for Legionella every 90 days

During use and at least 15 days prior to the pre-season (≤15 days before startup). Schedule dates now.

✔ Trigger remediation on thresholds

Clean, disinfect, retest. Exactly as the rule defines, don’t “watch and wait.”

✔ Use approved lab methods

Confirm critical findings with culture when appropriate.

✔ Bias for disinfection

When maintenance is overdue, the outbreak playbook explicitly ordered evaluation + disinfection when towers lacked recent treatment.

✔ Train field teams

In safe sampling, chain of custody, and data workflows, make environmental data easy to act on within hours, not days.

✔ Detect refrigerant leaks and keep your system efficient.

The Path Forward: When System Pressure Steals Attention From Water Treatment

Here’s the pattern we need to own: when plant conditions are under stress (heat waves, refrigerant leaks, fouled condensers, component failures), ops teams understandably scramble to keep cooling online.

But those same conditions push basin temperatures into Legionella’s comfort zone, alter flow, and dilute disinfectant residuals—precisely when treatment gets deprioritized.

That’s how a mechanical problem can become a public health crisis. (CDC: operate below the 77–113°F growth band where possible; automate disinfectant addition and monitor pH/residuals.

Frequent monitoring of water quality parameters is crucial for detecting issues early and ensuring system safety, particularly during periods of operational stress.

Maintaining safe drinking water quality is equally important, as contamination risks and infrastructure challenges can impact public health)

Source: CDC.

Refrigerant Leaks and the Chain of Risk

Refrigerant leaks are more than just a compliance issue or an energy drain; they are a hidden cofactor in Legionella outbreaks. The problem begins with reduced thermal performance.

A leaking system must work harder and may fail to maintain setpoint temperatures in condenser water loops. This can push water temperatures into the

“Legionella growth zone” of 77–113°F (25–45°C), creating ideal conditions for bacterial proliferation.

Furthermore, system stress caused by a leak can lead to extended stagnation. Strained systems may cycle less efficiently, resulting in reduced water turnover and the formation of dead zones where biofilms thrive.

These biofilms are particularly dangerous because they shield Legionella from disinfectants, making control efforts more challenging.

In essence, a refrigerant leak transforms a mechanical problem into a public health risk by undermining the very pillars of Legionella prevention: proper temperature control, consistent water circulation, and effective disinfection.

A leaking refrigerant circuit weakens heat rejection, raising condenser/tower water temperatures, and creating stagnation pockets—classic Legionella accelerators, as per CDC temperature guidance.

Even if you can’t “prove” the leak caused the bacteria, the temperature math and hydraulics are not your friends. (Operational inference, backed by CDC growth/temperature ranges.) Source: CDC

Outbreaks don’t wait while you fix the machine – In July–August 2025, New York City found Legionella pneumophila in 11 operable cooling towers across Central Harlem, with ~80 cases and 3 deaths; officials ordered immediate remediation.

Facilities teams were thrust “on the front lines,” because improperly cleaned HVAC/water systems can spread infectious aerosols via towers. Sources: Facilities Dive, ABC7 New York & New York Post

This is not new.

After the 2015 South Bronx crisis—138 cases, 16 deaths—NYC enacted Local Law 77, forcing registration, written maintenance programs, routine testing, and explicit remediation rules.

The NIH case study outlines the core requirements: register, inspect, and test at least every 90 days in use, have an ASHRAE-188 plan, and act on thresholds. Source PMC

“Local Law 77 sets stipulations for cooling tower registration and certification and imposes maintenance, inspection, and Legionella testing requirements.” Source PMC

Insight: Pressure diverts attention, and that’s when Legionella wins

When a chiller is leaking refrigerant, a condenser is fouled, or heat load spikes, teams focus (rationally) on “keeping the building up.”

But those same conditions raise water temperatures, reduce circulation, and degrade biocide efficacy—all pro-Legionella factors.

CDC’s 2025 guidance is blunt: keep tower water below the Legionella-favorable 77–113°F (25–45°C), automate dosing, and avoid stagnation. Source CDC

The NIH case study shows what happens when we don’t move fast: rules work only if acted upon—testing alone won’t save you. In 2015, NYC, the commissioner ordered overdue towers evaluated and disinfected within two weeks, then the Council locked in 90-day testing and ASHRAE-188 plans.

The message: maintenance needs decisive action during stress, not after. Source PMC

🤔 Have questions or concerns about Detecting Refrigerant Leaks?

Connect with us and explore how we can help you detect them efficiently.

Evidence: Under pressure, crews get stretched—and early signals get missed

2015 South Bronx

DOHMH had to train and deploy extra sampling teams on the fly and stand up new data workflows; speed and manpower were limiting factors. Source PMC

Harlem 2025

Officials linked clusters to towers, ordered cleanings, and raised penalties; reporting emphasizes FMs are the chokepoint where preventive steps either happen—or don’t. Source Facilities Dive & New York Post

Bottom Line

When the plant is screaming, water treatment gets crowded out unless it’s pre-scheduled, pre-resourced, and automated.

Actions: A playbook for leak management without sacrificing Legionella control

No-Pause Water Treatment” doctrine (operating rule #1) – When alarms fire or load spikes, you do not pause dosing, flushing, or monitoring.

You parallel them with a mechanical response. Build this into SOPs, PMs, and vendor contracts.

Five non-negotiables (the “Rule of 5” under stress):

- Documentation in real time

If it isn’t logged, it didn’t happen—especially during a crisis (audits and epidemiology rely on this). Update your Water Management Program (WMP) with any new controls or setpoints learned from the incident to ensure compliance with CDC, ASHRAE, and EPA guidelines. - Temperature guardrails

Alert at 77°F (25°C) tower basin average; escalate at 86°F (30°C). (Localize thresholds to your chemistry and tower OEM; CDC says stay below the 77–113°F zone.)

Source: CDC - Flow assurance

Prevent stagnation—balance cells, open bypasses, flush dead legs weekly, and rotate idle cells on timers.

Source: CDC - Residuals on rails

Automate biocide/oxidant feed; sample and log weekly bacteriologicals; do not defer because a chiller is down.

Source: CDC - Threshold actions

If routine Legionella tests hit action levels, clean, disinfect, re-test exactly per your plan—no “wait and see.” (This is what Local Law 77 and the NYC rules require.)

Source: PMC

Leak management that protects people, not just energy

Why leaks matter to pathogens?

Efficiency loss → warmer water

Leak-stressed chillers miss setpoints and lengthen tower run times; water lingers in the Legionella comfort range.

Source: CDC

Hydraulics drift

You see partial-load cells, throttled valves, or changed differentials; that’s stagnation risk.

Attention diversion

Techs chase the leak; the tower program slips a week—that’s enough time for biofilm to harden.

What to deploy?

Data fusion

Trend refrigerant alarms beside basin temperatures, delta-T, pump status, and chemical feed; one pane of glass, one timeline.

Continuous leak detection (AKO)

High-sensitivity fixed sensors and LDaaS alert you before thermal drift becomes a water-side problem; tie alarms to work orders and water checks.

Source: AKO & Carbon Connector

Event-linked water tasks

Any leak alarm should auto-schedule: immediate basin temp check, residual verification, and, if needed, a shock/clean cycle in parallel with mechanical repairs.

These actions should be part of a comprehensive water treatment program that includes chemical biocides, corrosion control, and monitoring protocols to ensure system safety and regulatory compliance.

A 72-hour runbook for “system under pressure”

Hour 0–4 (Alarm to Stabilization)

- Confirm alarm (LDaaS/BMS), isolate the likely circuit; open work order.

- Trigger linked water SOP: verify basin temp, confirm feed equipment running, pull dip slides or ATP (if in your validation plan).

- If the basin temperature is nearing your guardrail or the residual is out of spec, initiate corrective dosing immediately to control Legionella growth during system stress.

Hour 4–24 (Repair + Hold the line)

- Leak found? Start repair; don’t pause the water tower program.

- Balance cells/flows to avoid dead zones; verify drift eliminators and blowdown functioning.

- If you’ve crossed microbial or temperature action levels, clean and disinfect now; schedule post-treatment sampling per plan.

Hour 24–72 (Verification + Prevention)

- Root-cause the leak (vibration, seals, rubs, corrosion); plan a permanent fix and QA.

- Resample according to the plan (culture or rapid screening, as specified).

Documentation that stands up to regulators and epidemiologists (Trakref)

When Harlem-style scrutiny hits, your defense is time-stamped, complete records, mechanical and water-side.

Local Law 77 requires registration, written plans, 90-day Legionella testing in use, routine maintenance, threshold-based remediation, and enforcement via inspections/fines. Your system should make compliance easy to prove.

Legionella program documentation should include:

- Documentation of Legionella control measures implemented, such as system design, maintenance, and disinfection practices

- Registration and written water management plans

- Records of 90-day Legionella testing and results

- Routine maintenance logs

- Documentation of threshold-based remediation actions

- Evidence of enforcement activities (inspections/fines)

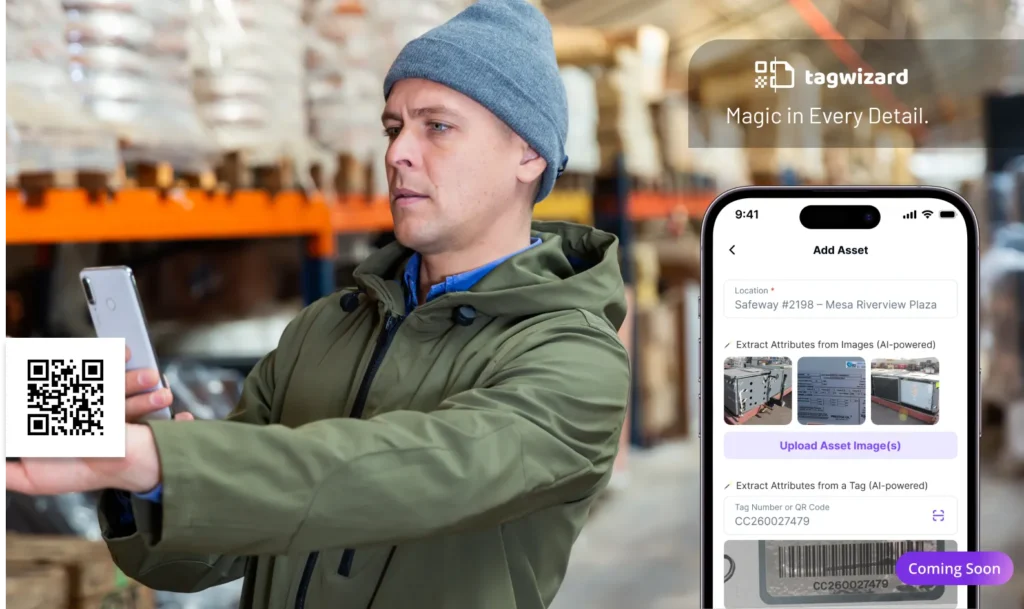

Tag it, Track it, Prove it: Turning Asset Labels into Health Guardrails.

When systems are under pressure, attention gets pulled to “keep the plant up”, and water treatment is the first thing to slip.

Tags, labels, and a rules-engine workflow are how you prevent that. When a technician scans a tag, it can also display reminders for required personal protective equipment (PPE) during maintenance or disinfection tasks.

They don’t just satisfy environmental compliance—they create operational guardrails that protect public health during heat waves, leak events, and outage triage.

✔ Spot HVAC leaks early to cut costs and energy waste.

Tag every asset, so maintenance, water treatment, and compliance can “snap” to the right unit

Why tagging isn’t optional in practice:

EPA Section 608 requires owners/operators of appliances with a refrigerant capacity of 50 pounds or more to maintain appliance-specific records, including service dates, quantities added, leak inspections, repair verification tests, and more.

This is further expanded to include systems 15 LBS and larger.

You cannot meet those obligations reliably without unique identification for each appliance; tagging (barcode/QR/RFID) is the practical way to ensure every entry ties to the right machine—every time. Source: US EPA

AIM Act labeling intersects here, too:

The EPA’s HFC program introduces labeling and record-keeping requirements for refrigerant containers (e.g., the implementation of reclaimed HFC labeling rules by 2026).

While this applies to cylinders, it encourages organizations to adopt traceable, labeled equipment and inventory throughout their operations, including systems with capacities as low as 15 LBS.

Source: ICC & US EPA

How to do it cleanly: Tag Wizard

Use Tag Wizard to digitize and standardize your tagging workflow.

You generate durable barcode/QR labels, enforce consistent naming/IDs, and tie each label to the asset’s digital record—compressors, condensers, cooling-tower cells, chemical feed systems, meters, even dead-leg valves. That makes field scanning fast and eliminates “mystery units.”

→ Read More About Tag Wizard, our asset tagging app

📌 Pro tip: Tag the tower cells and the feed equipment (pumps, controllers) separately. Most outbreaks are “local” failures (a warm cell, a stuck valve, a silent feeder) that don’t show up if you tag only the whole tower.

Minimum fields on the label & record (what the tech sees when they scan):

- Asset ID (human-readable + barcode/QR), location/roof zone, OEM, capacity

- Refrigerant type/charge (appliance), or cell ID (tower)

- Control limits (basin temp guardrails, disinfectant residual, pH)

- Service intervals (90-day Legionella test window; weekly bacteriologicals)

- Action links: “Leak alarm SOP” and “Legionella action SOP” (one tap)

Make the label a health guardrail, not just an environmental one

When a tech scans a tag, they should see both sets of guardrails instantly:

Environmental / EPA 608

Leak thresholds, repair deadlines, verification test due dates, and service log (date/type/qty added).

Source: US EPA

Public health / Legionella

CDC growth band reminder (77–113 °F / 25–45 °C), residual targets, sampling cadence, and immediate disinfection triggers if action levels are hit, aligned to ASHRAE 188/NYC rules, with references to guidance from the relevant public health authority.

Sources: Federal Register

That way, a refrigerant alarm can’t happen in a vacuum: the same scan exposes the water-side obligations that prevent outbreaks.

Structure responses with a rules engine (Trakref): one alarm → many required actions

You founded Trakref as a rules engine for refrigeration compliance.

Use it (or an equivalent CMMS) so any tagged alarm automatically creates linked tasks and deadlines, for both mechanical and water treatment:

Example: “Leak detected on CH-2 (tag scanned)” → auto-create:

Mechanical

Isolate circuit, repair plan by X hours, EPA leak-rate calc, verification test by Y days, reporting (if chronic). Source: US EPA

Water-side (paired)

Basin temperature checks at 0/2/8/24 h; confirm residual & pH; rotate cells/flush dead legs; clean/disinfect if guardrails breached; schedule re-sampling per plan (90-day program still holds). The rules engine can tailor required actions to the needs of the particular system involved.

Source: Federal Register

Documentation

Single, time-stamped timeline—alarm → repair → water checks → lab results → return-to-service package (downloadable for DOH/EPA).

The beauty of a rules engine is that no one has to remember; tags + rules generate the right playbook in seconds.

Data-first leak management (AKO) to keep towers out of the danger band

AKO Leak Detection (fixed NDIR transmitters + comms) gives continuous, high-sensitivity monitoring for HFCs/CO₂, feeding your rules engine and BMS.

You’re not waiting for performance to sag; you’re acting on earlier signals that correlate to heat-rejection stress. Tie AKO alarms to the asset’s tag and auto-launch the water-side SOP (above).

Source: AKO

Outcome: Fewer hours in the 77–113 °F basin zone, fewer stagnation pockets, fewer “missed” chemical feeds, and fewer chances for Legionella to get ahead.

These monitoring and control strategies are grounded in principles of environmental science to ensure effective Legionella prevention. (CDC: automate disinfectant addition and monitor residual/pH continuously where possible.)

Source: Federal Register

What your auditor (or epidemiologist) expects to see, because the tags made it possible

From a single tagged asset record, you should be able to export:

EPA 608 trail

Service dates/types, refrigerant added, leak-rate calcs, repair timelines, verification test results.

Source: US EPA

AIM/HFC links

Cylinder labels/receipts (reclaimed content labeling as applicable).

Source: ICC

Legionella program

Last four 90-day cultures while in use; pre-season test ≤15 days before startup; shock/clean logs; post-disinfection sampling; drift eliminator checks; documentation of measures taken to control waterborne pathogens in the system. (Mapped to site plan per ASHRAE 188/NYC program expectations.)

Source: Federal Register

If a Harlem-style cluster hits your ZIP code, the combined mechanical + water export closes exposure windows and proves control—fast.

Implementation Checklist

✔ Deploy the Tag Wizard

Assign unique IDs and scannable labels to every air conditioning and refrigeration component, as well as tower components (including cells and feed gear), and to drinking fountains and other water fixtures, ensuring they are included in the monitoring program.

Source: Carbon Connector

✔ Map guardrails

to each tag (EPA leak rules + CDC/ASHRAE water limits) so the health and environmental obligations appear together.

Sources: US EPA & Federal Register

✔ Wire AKO leak detection and apply LDAAS to your rules engine, such as Trakref, so that a leak alarm automatically triggers the paired water-treatment SOP.

Source: AKO

✔ Run Trakref (rules engine)

So tasks, deadlines, and documentation spawn from the tag—no memory, no guesswork; just execution.

Source: Fexa Trakref

✔ Audit Monthly

Pull a one-click export from tagged assets (EPA 608 logs, HFC labels, and Legionella sampling/remediation) into a single PDF you’d be proud to hand DOH.

That’s how labels become lifelines: not just barcodes for inventory, but automated triggers that keep maintenance, compliance, and public health locked together when your system is under the most pressure.

Regulatory objects

Local Law 77 annual certification, 90-day Legionella test records, pre-season startup tests (≤15 days prior), DOHMH communications, any Notices of Violation, CAPA items and due dates.

Dashboards & Audit Exports

- Leak rate vs. basin temperature trend; time-to-action KPI (alarm→water check, alarm→repair); 90-day test compliance; remediation cycle times; open CAPA aging.

- One-click export for inspectors: asset list, WMP excerpt, last 12 months’ tests, all leak-linked water actions.

📌 It’s a powerful statement that HVAC is a matter of life and death, and it’s the truth that guides the most vigilant among us. We can’t simply track activity because we’re told to. The true path to safety lies in empowering our frontline teams, giving them the knowledge and tools they need to be the first and last line of defense.

This isn’t a story about compliance; it’s a call to elevate the work of our maintenance professionals and support their vigilance.

A New Standard of Vigilance: Beyond the Checklist

The fight against Legionella is a continuous, year-round effort that demands a new standard of vigilance. Regulations, while essential, are just the framework; the true defense lies in empowering our frontline teams to protect human life.

This mission is urgent. The official number of Legionnaires’ disease cases is likely just a fraction of the total, with many infections going undiagnosed and unreported.

For every tragic outbreak, there are countless hidden system failures. It is a reality that an elderly person’s life can be “brought to a stop” by pneumonia caused by maintenance neglect and high temperatures in a cooling system.

This is why a proactive approach is not merely a best practice; it is a moral and legal obligation.

The Overlooked Link: From Mechanical Failure to Public Health Risk Management

Rarely is HVAC considered a matter of life and death, but with Legionella, this is precisely the case. A seemingly isolated refrigerant leak is a hidden cofactor in an outbreak.

A leak can reduce thermal performance, pushing water temperatures into the “Legionella growth zone” of 77–113°F, thereby undermining temperature control.

This system stress also leads to reduced water turnover and biofilm formation, which shields the bacteria from disinfectants.

Empowering the Front Line: A Proactive Playbook

To counter this risk, we must empower our frontline teams by providing them with the necessary tools and knowledge to remain vigilant. This starts with tagging critical assets and integrating their data into an intelligent workflow.

1. Tag Every Asset

The first step is to turn our physical assets into intelligent, traceable data points. We can do this by assigning each critical component a unique digital identity. This isn’t just about barcodes; it’s about connecting every piece of equipment to a wealth of knowledge and a clear set of instructions.

Cooling Tower Cell #4 (CT-4)

Tagged with its location, a digital copy of its ASHRAE 188-compliant maintenance plan, and its unique registration number. This single tag is a link to all the rules that govern this asset.

Chiller Circuit A (CH-A)

Tagged with its refrigerant type and charge, EPA 608 leak thresholds, and the due dates for its next verification test. It is also linked to its partner asset, Cooling Tower Cell #4.

AKO Leak Detector

Positioned near the chiller, this detector is a sentinel. It’s tagged to alert us to any refrigerant loss, providing the earliest possible warning of a potential mechanical problem.

2. Proactive Workflow: A Story of Integrated Safety

Let’s track some activity. Imagine a scenario where a technician receives an alert from the AKO leak detector. The alarm indicates a minor refrigerant loss from Chiller Circuit A.

Instead of a frantic search for paperwork, the technician scans the tag on the chiller.

The system instantly presents the EPA 608 repair protocols, but more importantly, it simultaneously flags the interconnected public health risks associated with these protocols.

The tag reminds the technician that this leak could lead to a loss of thermal performance, pushing the cooling tower water temperature into the dangerous Legionella growth zone of 77–113°F (25–45°C).

The system then guides a series of immediate, linked actions:

Mechanical Response

The technician follows the EPA-mandated repair plan and schedules a verification test.

Public Health Response

The system automatically generates a new task to check the basin temperature in Cooling Tower Cell #4 and verify the disinfectant residual and pH levels.

This ensures that the water-side risks are addressed in parallel with the mechanical repair, not after.

3. Elevating Knowledge, Elevating Safety

This process is about more than just checking boxes. It’s about elevating the knowledge of our frontline team so they can protect us all.

When the technician scans the tag, they don’t just get a task list; they get a holistic view of the system’s health. They view the real-time data from the leak detector alongside the temperature readings from the cooling tower, providing a deeper understanding of the cause-and-effect relationship between their work and public health.

This type of integrated knowledge is a powerful tool that transforms a routine maintenance task into a moment of true vigilance.

We can talk about regulations and fines, but the most compelling reason for this work is the knowledge that every action taken, every leak detected, and every temperature check performed is a step toward preventing a preventable illness.

This approach, which supports our frontline teams with the knowledge and tools they need to be vigilant, is the single most reliable way to keep our communities safe.

The key to this proactive approach is AKO Leak Detection, a continuous monitoring system that identifies refrigerant leaks with high sensitivity. An AKO alarm isn’t just a mechanical alert; it’s a warning that the system is under stress, creating the very “hot spots” where Legionella thrives.

This integrated approach transforms maintenance from a reactive checklist into a proactive, purpose-driven playbook.

It empowers our teams to act, not just because they have to, but because they understand that their vigilance is the first and most critical safeguard of human life.

Risk Factors for Legionella Contamination

System Design and Age: How legacy infrastructure and complex piping create hidden harbors

The design and age of your building’s water systems play a critical role in the risk of Legionella contamination. Older infrastructure, especially in facilities with legacy cooling towers and complex piping networks, often harbors hidden pockets where water can stagnate and biofilms can form.

These concealed areas—such as unused branches, oversized pipes, or intricate loops—provide ideal conditions for Legionella bacteria to thrive, especially when regular risk management and maintenance are lacking.

Industrial processes that rely on multiple cooling towers or extensive water distribution systems are particularly vulnerable. Over time, corrosion, scale buildup, and changes in system configuration can further complicate water flow, making it even easier for Legionella growth to go undetected.

Without a proactive risk management approach, these hidden harbors can become persistent sources of Legionella contamination, increasing the likelihood of Legionnaires’ disease outbreaks.

To mitigate these risks, facility managers should prioritize regular inspections, system mapping, and targeted maintenance of older water systems.

Upgrading outdated components, removing unnecessary pipework, and implementing a robust water management program are essential steps in controlling Legionella and protecting public health.

Stagnant Water and Low Flow: The silent invitation for bacterial growth

Stagnant water and low flow conditions are among the most significant contributors to Legionella growth in water systems. When water sits idle in cooling tower systems—especially in dead legs or infrequently used sections of piping—it creates a perfect environment for Legionella bacteria to multiply.

These stagnant zones not only support Legionella growth but also make it difficult for disinfectants to reach and eliminate microbial threats.

Dead legs, or sections of pipe where water does not circulate, are notorious for supporting Legionella growth. Inadequate water flow can also result from improperly balanced systems, closed valves, or underutilized cooling tower cells.

To counteract these risks, it is essential to implement control measures such as routine flushing of dead legs, maintaining consistent water flow throughout the system, and adhering to a comprehensive water treatment program.

Regular monitoring and proactive maintenance are key to preventing stagnant water from becoming a silent invitation for bacterial growth.

📌 By ensuring that all parts of the water system remain active and well-treated, facility managers can significantly reduce the risk of Legionella contamination.

Temperature Control Failures: When cooling towers drift into the danger zone

Maintaining precise temperature control in cooling towers is vital for preventing Legionella growth. The bacteria flourish in water temperatures between 77°F and 113°F (25°C–45°C), making any lapse in temperature regulation a serious risk factor for Legionella contamination. When cooling tower systems experience temperature control failures—whether due to equipment malfunction, poor system design, or inadequate monitoring—water can easily drift into this danger zone.

Even brief periods of elevated water temperature can allow Legionella to multiply rapidly, especially if other risk factors like biofilm or stagnant water are present. To prevent this, cooling tower systems must be designed with reliable temperature controls and equipped with sensors that provide real-time monitoring. Regular maintenance and prompt response to any deviations in water temperature are essential to keep the system operating safely.

📌 By prioritizing temperature control and ensuring that water remains outside the Legionella growth range, facility managers can effectively reduce the risk of Legionella contamination and protect building occupants from developing Legionnaires’ disease.

Inadequate Water Treatment: Gaps in chemical dosing, monitoring, and maintenance

Effective water treatment is the cornerstone of Legionella control in building water systems. When there are gaps in chemical dosing, inconsistent monitoring, or lapses in routine maintenance, the risk of Legionella growth increases dramatically. Inadequate water treatment allows biofilms and other microbial communities to establish themselves, creating a protective environment for Legionella bacteria.

To maintain high water quality and prevent Legionella contamination, it is essential to implement a rigorous water treatment program.

This includes regular testing for Legionella and other waterborne pathogens, precise chemical dosing to maintain disinfectant residuals, and ongoing monitoring of key water quality parameters.

Maintenance teams should also ensure that all water treatment equipment is functioning correctly and that any issues are addressed promptly.

📌 By closing the gaps in water treatment and maintaining a consistent, proactive approach, facility managers can safeguard their water systems against Legionella growth and ensure compliance with public health regulations.

External Contaminants: Construction, dust, and organic debris as risk multipliers

External contaminants such as construction dust, organic debris, and airborne particulates can significantly increase the risk of Legionella contamination in water systems.

During construction or renovation activities, dust and debris can be drawn into air conditioning units and cooling towers through building air intakes, introducing additional nutrients and microorganisms that support Legionella bacteria.

Cooling tower basins are particularly vulnerable to the accumulation of organic material, which can fuel bacterial growth if not regularly cleaned.

To mitigate these risks, it is essential to implement control measures such as frequent cleaning of cooling tower basins and air intakes, as well as the installation of high-efficiency drift eliminators to reduce the spread of contaminated water droplets.

The use of ultraviolet light as a supplemental disinfection method can also help control microbial growth and reduce the risk of Legionella contamination.

📌 By maintaining strict housekeeping practices and employing advanced control measures, facility managers can minimize the impact of external contaminants and strengthen their overall Legionella control strategy.