The Cold War Is Over In Refrigerant Leak Detection

Table of Contents

ToggleWhy We Must Move Beyond the Old Battles

Machine Learning, Refrigerant Leaks, and the Next Frontier of Trust in HVAC/R

For decades, the HVAC/R industry has fought its own kind of Cold War, a war not of nations, but of noise. Leak detection has long been an uneasy battlefield, divided between outdated sensors that triggered nuisance alarms and reactive repair strategies that drained both budgets and trust.

In this long struggle, the frontlines were grocery aisles, server rooms, plant floors, and commercial refrigeration environments (spaces where technicians, armed with soap bubbles, handheld sniffers, and binders of paperwork, were sent to hunt for invisible enemies.

Too often, they came back empty-handed or late, the damage already done, the refrigerant already gone, and the trust already broken.

This stalemate shaped an entire industrial culture. Leaks were accepted as inevitable. Compliance became a game of penalties and paperwork.

The workforce bore the burden of late-night truck rolls, burnout, and rising costs. Every leak wasn’t just a technical failure; it was a systemic one, a breakdown of communication between machines, people, and regulators.

Issues like refrigerant leaks and trust gaps don’t just impact individual components; they infect the entire ecosystem of HVAC/R reliability, causing inefficiencies that cascade through operations.

These inefficiencies ultimately affect customers, leading to discomfort, higher costs, and reduced confidence in system performance.

Reliable leak detection is essential not only for operational efficiency but also for ensuring customer satisfaction and trust. For managers and regulators, leak detection became a reactive

burden instead of a proactive science. And for decades, one question echoed across the industry: why can’t we find leaks before they find us?

Too Long Didn’t Read

- NDIR hardware

Patented infrared sensing that identifies refrigerants by their unique “fingerprint,” not just by concentration. - LDaaS layer

Cloud analytics stitches in service records, charge sizes, and store context — so a sensor event becomes a prioritized work order. - Outcome

Near-zero false positives, faster leak confirmation, less wasted gas, and fewer unnecessary truck rolls. - Relatable frame

Think of it like debugging messy code: the patent ensures the sensor can tell signal from noise, and the service layer translates that into fixes you can actually act on.

Refrigerant leak detection is a critical aspect of maintaining HVAC and refrigeration systems, from residential air conditioners to complex commercial refrigeration units.

Monitoring for symptoms such as reduced cooling efficiency, unexplained increases in energy bills, or visible signs of moisture or oily residues can help identify leaks early.

Regular maintenance routines (like inspecting connections, checking for moisture accumulation, performing deep vacuum tests, and conducting a leak test or pressure test) are vital for catching leaks before they impact system performance or cause costly repairs.

🚨 Explore how smart leak detection keeps cooling efficient and sustainable

Introduction to Refrigerant Leak Detection

Refrigerant leak detection defines system excellence. Performance, safety, and efficiency all depend on this foundational process.

Small leaks quietly erode cooling power. Large ones devastate energy budgets and threaten environmental safety.

Detection isn’t just technical maintenance. It’s the cornerstone of every cooling system’s health, from residential units to complex commercial installations.

Leaks emerge where systems are most vulnerable. Evaporator coils. Refrigerant lines. Valves. Poor installation creates weak points. Environmental stress amplifies them.

Physical damage exposes them. Even minor leaks compound into major failures. Warm air replaces cool comfort. Energy bills climb without warning.

Cooling performance degrades steadily. Early detection prevents this cascade. Smart repair preserves peak efficiency.

Modern detection methods work with quite precision. Visual inspections catch obvious signs. Pressure testing reveals hidden weaknesses. Advanced systems deploy sensors and machine learning to monitor continuously for refrigerant loss.

🚨 Refrigerant leak detection is the backbone of system health.

Catch issues early to protect performance, safety, and energy costs.

Regular maintenance routines inspect connections, check moisture accumulation, and perform deep vacuum tests.

These methods catch problems before they impact performance. Before they demand costly repairs. In commercial refrigeration, where perishable goods depend on consistent temperatures, accurate detection becomes critical.

Proactive detection extends equipment life. Reduces energy consumption. Eliminates unexpected downtime. Building owners and facility managers gain control through vigilant monitoring. Reduced cooling efficiency signals trouble.

Unexplained energy increases demand for investigation. Visible moisture or oily residue reveals leak locations. Early identification protects the investment. Preventative measures support sustainability by minimizing refrigerant emissions and energy waste.

Effective leak detection transcends problem-solving. It ensures long-term performance, safety, and efficiency across every cooling unit. Regular inspections work alongside advanced detection technologies.

Quick responses to trouble signs safeguard investments and control energy costs. The result: systems that perform as designed, efficiency that endures, and a sustainable future built on precise, proactive care.

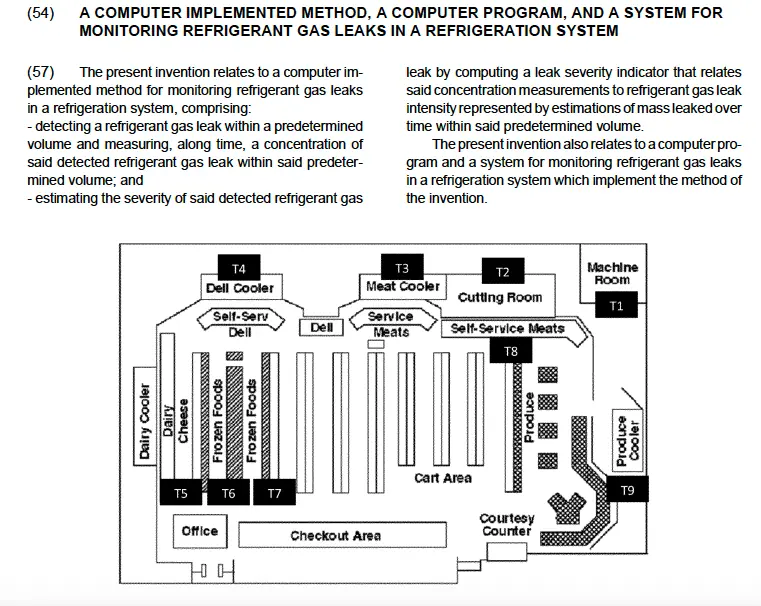

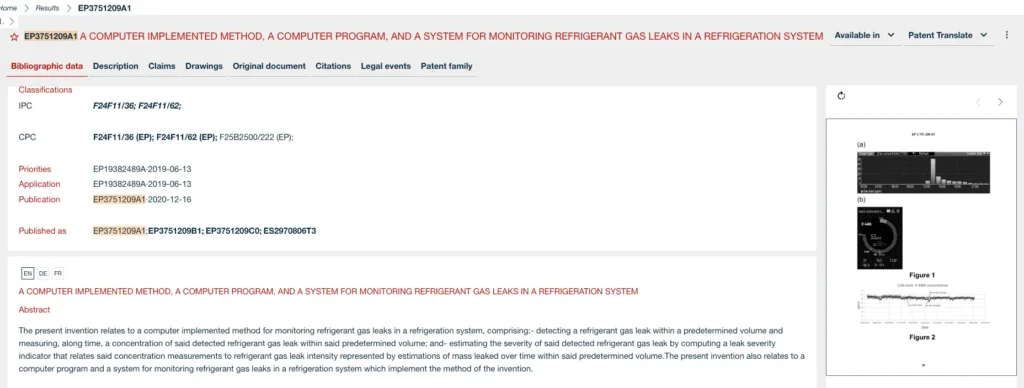

A Turning Point: The AKO Patent

On August 13, 2024, the European Patent Office formally granted AKO Electromecánica, S.A.L. a landmark patent (EP 3 751 209 B1 / WO 2019/197607) that changes the very terms of this long technological war.

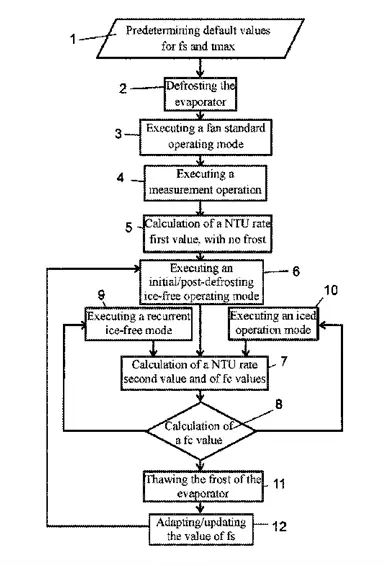

The patent is deceptively simple in title: a method for detecting refrigerant leaks by comparing expected versus actual receiver liquid levels through machine learning. But beneath that straightforward description lies a profound shift in how refrigeration systems are understood, monitored, and trusted.

At its heart, the patent captures a breakthrough in applied intelligence: using Extremely Randomized Trees (ExtraTrees) (a type of ensemble machine learning model )to build a predictive baseline for how a refrigeration system should behave.

The method trains on historical data (liquid levels, temperatures, compressor cycles, suction and discharge pressures) until the algorithm learns what “normal” looks like for each system.

When real-time data begins to deviate from that learned baseline, even subtly, the model identifies the anomaly. The result is precision leak profiling: identifying small leaks before they evolve into catastrophic ones, long before manual inspection or conventional threshold-based alarms would trigger.

The AKO solution is an automated system that leverages machine learning to enhance leak detection accuracy and reliability throughout the manufacturing process.

This is not just a technical evolution. It is a trust revolution. Where legacy detectors produced endless false positives (screaming wolf at every fluctuation), AKO’s patented approach filters out the noise, recognizes true deviations, and quantifies their severity. It replaces suspicion with confidence.

That distinction is why the patent matters. It isn’t about detecting leaks; it’s about restoring faith in detection itself. By merging field-hardened sensing hardware with intelligent analytics, AKO’s approach redefines reliability; not just as performance, but as credibility.

The Human Story Behind the Patent

The breakthrough described in EP 3 751 209 A1 didn’t emerge from a sterile research lab or a sudden stroke of genius. It was born from persistence, frustration, and deep field experience, the kind only gained by engineers who live inside the problem they’re trying to solve.

It was the work of two Spanish engineers (Xavier Albets Chico and Miguel Ángel González Sánchez) who spent over a decade inside AKO’s tight-knit culture, confronting the same challenges technicians and contractors face daily.

In the early 2010s, the refrigeration industry was stuck in a pattern of frustration. Leak detectors existed everywhere, but trust in them had eroded. They generated false alarms that triggered costly, unnecessary service calls. Technicians worked overtime chasing ghosts, while real leaks slipped past unnoticed until they caused system failures, product losses, and regulatory violations.

The very tools meant to prevent chaos had become part of it.

Albets Chico and González Sánchez saw this firsthand, standing shoulder-to-shoulder with technicians in cold rooms, listening to their complaints, watching their skepticism grow.

They understood this wasn’t just a sensor problem; it was a human one.

If detectors couldn’t separate signal from noise, people would stop believing them. And when trust in detection fails, compliance fails, and systems fail.

The two engineers decided to reframe the problem entirely. Instead of chasing “perfect hardware,” they studied how signals behaved in the messy reality of field conditions — fluctuating temperatures, changing airflow, background gases like CO₂ from forklifts and cleaning products.

The question they asked changed everything:

“What if the answer isn’t a smarter sensor, but a smarter interpreter?”

That philosophical shift became the heart of their patent. It meant accepting that the physical world would always be noisy, but our interpretation of it didn’t have to be.

After countless iterations, prototypes, and late-night field tests, the AKO team produced a model that didn’t just measure, it understood. It validated, filtered, and contextualized each reading, ensuring that only meaningful alarms reached human operators.

When EP 3 751 209 A1 was finally filed in 2020, it wasn’t just a legal milestone. It was a testament to engineering persistence.

AKO hadn’t invented a gadget; they had rebuilt the bridge between technology and trust.

“We didn’t file this patent to protect an idea”

“We filed it to protect integrity to show that our engineers had solved a problem the whole industry was tired of pretending didn’t exist.”

This, then, was not a claim of ownership. It was a declaration of credibility.

Beyond Compliance: A New Paradigm of Proactive Detection

The timing could not be more relevant. By 2025, the regulatory landscape around refrigerants will have tightened dramatically.

The EPA’s AIM Act now enforces stricter thresholds on HFC use.

CARB in California, NYSDEC in New York, and Washington Ecology have all layered additional reporting and ALDS (Automatic Leak Detection System) mandates.

Leak detection is no longer just an efficiency measure; it’s a climate liability. Every unaddressed leak translates directly into Scope 1 emissions, measurable, reportable, and increasingly penalized under frameworks like SB 253 and the CSRD.

In this world, reactive detection (the “Cold War” status quo) cannot survive. The AKO patent represents the pivot point: the move from chasing leaks to predicting them, from regulatory burden to operational foresight.

With AKO’s method, compliance transforms from a chore into a strategic asset. Machine learning enables real-time profiling, triage, and verification, empowering field teams to act before systems degrade.

It’s not just better engineering; it’s future-proof regulation made practical.

🚨 Beyond compliance

Turn leak detection into operational foresight with AKO’s ML-powered method, built for today’s stricter AIM/CARB-era rules.

Understanding the Hidden Enemy: Signs of Refrigerant Leaks

Refrigerant leaks are silent saboteurs. They quietly undermine cooling performance, inflate energy costs, and degrade equipment life long before a system fails.

Warm air from vents, rising utility bills, or uneven cooling aren’t just maintenance issues, they’re early warnings. Likewise, oily residues around evaporator coils or moist patches along refrigerant lines signal compromised integrity.

Each small leak is a compounding problem: efficiency loss, environmental harm, and operational stress. Early, intelligent detection transforms these weak signals into opportunities for intervention.

Unmasking the Source: Causes of Refrigerant Leaks

Leaks don’t emerge from nowhere. They are the cumulative result of corrosion, vibration, installation flaws, and mechanical fatigue.

Moisture and airborne chemicals eat away at coils and lines; compressors vibrate fittings loose; rushed installation leaves microfractures that worsen over time.

By analyzing the data patterns across thousands of connected systems, AKO’s models now recognize these precursors.

It’s not just about finding leaks; it’s about understanding why they happen and predicting where the next one will occur.

One of the most common culprits is corrosion.

Over time, exposure to moisture, humidity, and airborne contaminants can eat away at metal components, especially in evaporator coils and refrigerant lines. This gradual deterioration creates tiny holes or cracks, allowing refrigerant to escape and reducing the system’s ability to deliver cool air efficiently.

Vibration and mechanical stress are also significant contributors.

As HVAC/R systems operate, compressors and other moving parts can cause refrigerant lines to vibrate or rub against other components. This constant movement can weaken joints, fittings, and connections, eventually leading to leaks that compromise both cooling and energy efficiency.

Poor installation practices, such as improper brazing, loose fittings, or inadequate sealing, can introduce vulnerabilities from day one.

Even a small oversight during installation can create a weak point where refrigerant can slowly leak out, driving up energy consumption and reducing overall system efficiency.

Physical damage from external sources, like accidental impacts during maintenance or construction, can puncture or deform refrigerant lines.

Environmental factors, such as extreme temperature swings or chemical exposure, can further accelerate wear and tear, making leaks more likely over time.

By unmasking these underlying issues, facility managers and technicians can take targeted action to prevent refrigerant leaks before they start.

Proactive measures (like regular inspections, proper installation, and addressing sources of corrosion or vibration) help maintain optimal cooling performance, lower energy costs, and extend the life of an AC or Refrigeration systems.

Ultimately, understanding and addressing the root causes of refrigerant leaks is key to achieving long-term efficiency, reliability, and environmental responsibility in any cooling or refrigeration environment.

Anatomy of a System: Cooling Components at Risk

Every air conditioning system is a network of interconnected components, each playing a vital role in delivering cool air and maintaining peak efficiency. At the heart of this system are the evaporator coil, compressor, and refrigerant lines; components that are especially vulnerable to refrigerant leaks.

Refrigerant acts as the ‘fuel’ for the air conditioning system, powering the thermal transfer cycle and enabling efficient cooling.

The evaporator coil, responsible for absorbing heat from indoor air, is particularly at risk due to corrosion or the effects of formic acid, which can eat away at the metal over time.

Such damage not only leads to leaks but also reduces the coil’s ability to transfer heat, undermining overall cooling efficiency and increasing energy consumption.

Refrigerant lines, which transport refrigerant between the indoor and outdoor units, often consist of copper tubing that can develop leaks from poor installation, vibration, or physical damage caused by environmental factors.

Tubing is particularly susceptible to corrosion and physical damage, which can lead to leaks and substantial refrigerant loss, ultimately affecting system performance and increasing energy costs.

The compressor, tasked with circulating refrigerant throughout the system, is also at risk if leaks go undetected, as it may be forced to operate under strain, leading to premature failure.

Understanding the anatomy of the air conditioning system (and the vulnerabilities of each component)empowers operators to identify potential risks before they escalate.

Regular maintenance, such as cleaning the evaporator coil and inspecting refrigerant lines and tubing for signs of corrosion or damage, is essential for preventing leaks and ensuring the system continues to deliver reliable, efficient cooling.

The Role of HVAC Systems in Energy Efficiency

HVAC systems are the backbone of building comfort and operational efficiency, but their impact on energy consumption is profound.

A well-maintained air conditioning system doesn’t just keep occupants comfortable; it plays a pivotal role in controlling energy costs and supporting sustainability goals.

However, even minor refrigerant leaks can quietly erode this efficiency, forcing the system to work harder to deliver the same level of cooling. This increased workload translates directly into higher energy bills and unnecessary energy consumption, undermining both financial and environmental objectives.

Regular leak detection and preventative maintenance are essential strategies for preserving the energy efficiency of any air conditioning system.

By identifying and repairing refrigerant leaks early, building owners can prevent the gradual decline in system performance that leads to wasted energy and rising costs.

Proactive maintenance ensures that the HVAC system operates at peak efficiency, minimizing energy waste and reducing the building’s carbon footprint.

In today’s regulatory and economic climate, maintaining optimal HVAC performance isn’t just about comfort; it’s a critical component of responsible building management and long-term cost control.

Technical Details: From Raw Signals to Strategic Precision

Leak detection has long been framed as binary: leaking or not. The AKO patent dismantles that false simplicity.

The patented method introduces a multi-layered architecture that detects, quantifies, and contextualizes leaks in a single continuous process. It even integrates vacuum verification and pressure testing protocols to ensure data integrity before system commissioning.

🚨 From raw signals to strategic precision

AKO’s patented, multi-layer method detects, quantifies, and contextualizes leaks, with built-in vacuum and pressure verification before commissioning.

Detection & Measurement: The Eyes and Ears

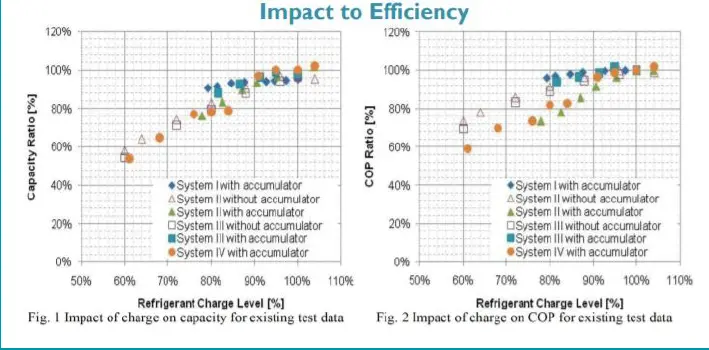

AKO’s NDIR sensors outperform traditional MOS sensors, achieving <5 ppm sensitivity versus ~50 ppm with fewer false alarms.

Each sensor streams concentration data continuously, turning time-stamped ppm readings into meaningful patterns.

Estimation of Severity: From ppm to kg/year

AKO’s proprietary indices (Leak Potential Index (LPI) and Leak Charge Index (LCI)) transform ppm readings into quantified, annualized refrigerant loss projections.

Example: a 53 ppm reading in a Madrid cold room equates to ~49.3 kg/year, or 35% of system charge; reframing an invisible threat into financial and environmental metrics.

Localization: Precision in Space and Time

Using stabilization times across multiple sensors, AKO triangulates leak positions in 3D and even identifies recurring events (via the Time–Gas Concentration Index, TGCI) such as leaks triggered during defrost cycles.

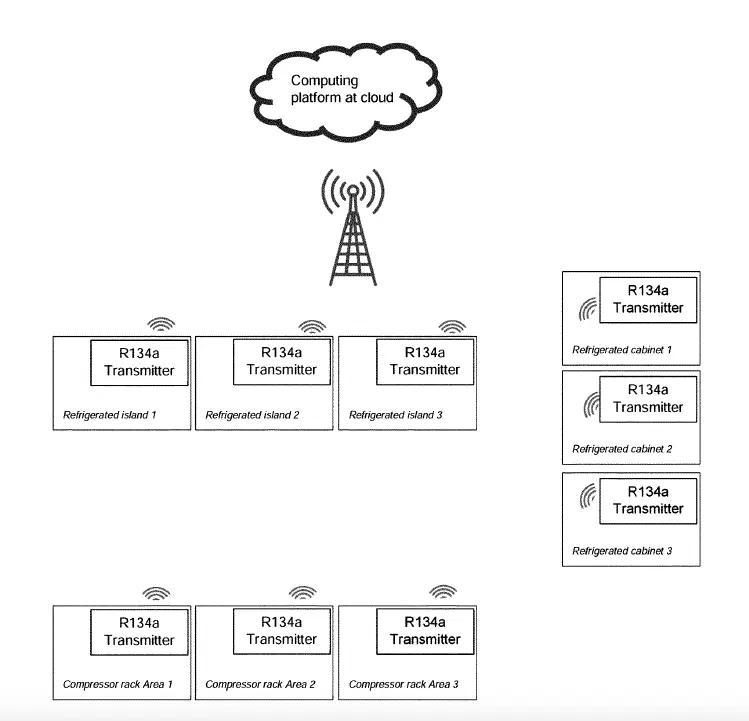

Connectivity: Dual Communication Paths

- RS-485 MODBUS for wired reliability.

- NB-IoT wireless for deep penetration, low-power longevity, and cost-efficient scalability: ideal for cold rooms, basements, and remote racks.

The result

>90% accuracy, >60% reduction in false alarms, and detection latency measured in hours or days instead of weeks.

The inventors also foresaw the deployment challenge: leaks occur in environments as varied as open supermarkets and deep freezer basements.

The system therefore supports:

- Wired RS-485 MODBUS for robust, always-on facilities.

- Wireless NB-IoT modules, chosen for three strategic advantages:

- Deep penetration through concrete and metal, reaching sensors in hard-to-access cold rooms.

- Low power consumption, enabling years-long battery life.

- Cost efficiency, with lower device and data costs, makes large-scale rollouts feasible.

This combination of hardware, computation, and communication makes the system adaptable across both legacy and new-build facilities.

Benchmark Performance

In validation studies:

- Leak detection accuracy exceeded 90% when compared against traditional ppm-only alarms.

- False alarms dropped by over 60%, restoring technician trust.

- Detection latency was reduced from weeks (typical with manual inspections) to hours or days, depending on leak severity.

These numbers are not incremental improvements, they represent a structural redefinition of what “early detection” means in HVAC/R.

Cooling System Efficiency: The Ripple Effect of Early Leak Detection

The efficiency of a cooling system hinges on its ability to maintain the right refrigerant charge and operate without interruption.

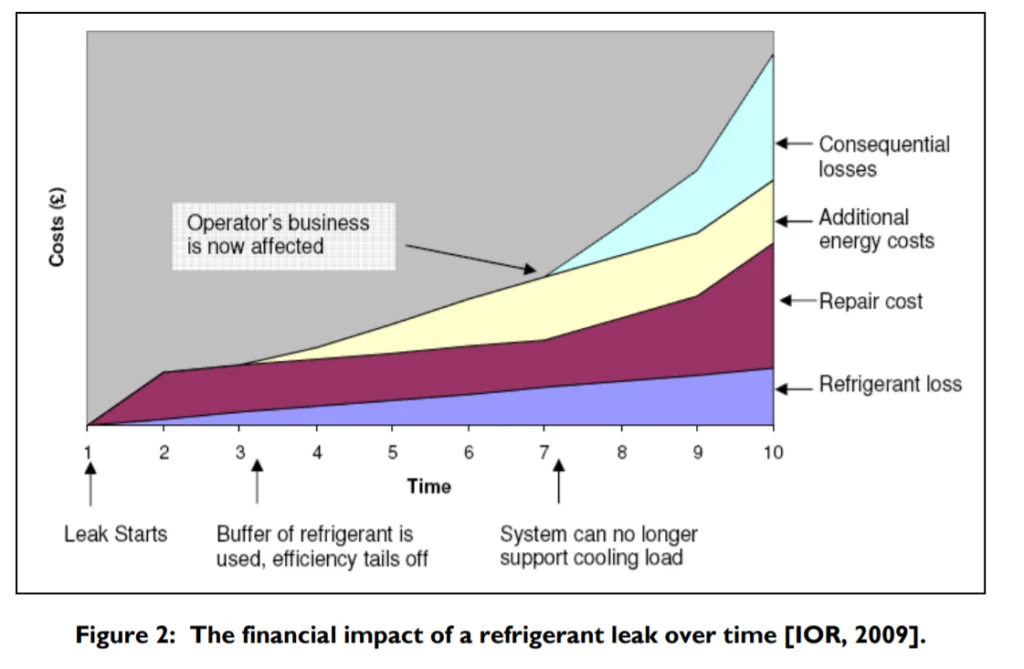

When refrigerant leaks go undetected, the consequences ripple through the entire system: cooling efficiency drops, energy consumption rises, and energy bills climb.

What starts as a small leak can quickly escalate, causing the cooling unit to run longer and harder, straining components and increasing the risk of breakdowns.

Early leak detection is the key to breaking this cycle. By catching refrigerant leaks before they become major problems, facility managers can protect the performance of their cooling systems, avoid costly repairs, and keep energy costs in check.

Routine maintenance and advanced leak detection technologies help identify issues at their source, allowing for timely intervention that preserves both equipment and efficiency.

In addition to financial savings, early detection supports environmental responsibility by reducing refrigerant emissions and minimizing the system’s impact on climate change.

Ultimately, a proactive approach to leak detection ensures that cooling systems deliver reliable, efficient performance in the long run.

The Next Frontier: Trust as Infrastructure

But this story is not just about algorithms. It is about trust: trust between machines and operators, between compliance officers and regulators, between managers and the workforce.

The AKO patent is a technical step, but its real value lies in re-establishing this trust.

Leaks are not just refrigerant losses; they are trust leaks.

Every time a detector cries wolf, trust erodes. Every time a technician spends hours on a wild goose chase, faith in the system diminishes. Every time an asset fails outside of hours, it is not just a compliance clock that resets, but the fragile bond between workers, managers, and technology.

By embedding predictive intelligence into the everyday fabric of refrigeration, AKO proposes something larger: that leak detection can transition from being an annoyance to being an ally.

With earlier intervention and reduced wear from undetected leaks, predictive intelligence directly supports equipment longevity, helping to protect the lifespan of essential HVAC and refrigeration components.

It can be the extra set of eyes and ears that the industry sorely needs in an era of technician shortages and escalating climate accountability.

The Patent as Proof, Not Protection

AKO’s patent was never about fencing off innovation. It was about proving integrity.

By choosing Europe (not as a limitation, but as a proving ground), AKO documented a breakthrough for all to see.

“We didn’t patent to block others”

“We patented to raise the standard. To show that machine learning belongs in the real world, not just in research papers.”

While others, like Axiom Cloud, are now filing U.S. patents around AI-based detection, AKO’s European patent stands as the foundation, the first, field-proven blueprint. It defines what “AI leak detection” means in practice.

In that sense, AKO isn’t fighting a patent war; it’s closing the Cold War.

How AKO NDIR Powers ALDS Compliance

Core Principle: NDIR Sensing

- AKO’s detectors use nondispersive infrared (NDIR) sensors, tuned to the specific absorption bands of refrigerant molecules (C–F bonds).

- Unlike generic gas sensors, these units are highly selective and maintain stability over years, meaning fewer recalibrations and fewer false alarms.

Automatic Leak Detection (ALDS) Compliance

- EPA AIM Act Subpart F and California CARB require ALDS for systems over specific charge thresholds.

- AKO’s NDIR detectors meet these requirements by:

- Constant monitoring (24/7, no inspection gaps) of all critical leak points, including valves, connections, and fittings, which are common sources of refrigerant leaks and essential for compliance.

- < 10 ppm detection sensitivity (well below regulatory thresholds).

- Self-diagnostics to ensure uptime, calibration integrity, and recordkeeping for auditors.

- The detectors provide real-time digital signals to the AKOnet Cloud platform, creating a continuous audit trail.

Networked Intelligence

- Individual detectors are not islands. They link to a control panel, then into AKOnet Cloud, where they’re assigned to specific assets.

- This creates a direct bridge between hardware compliance (the sensor meeting ppm rules) and regulatory reporting (the site meeting ALDS obligations).

🚨 Meet ALDS requirements with always-on NDIR monitoring

<10 ppm sensitivity, and a cloud audit trail built for auditors.

LDaaS: The Services Layer on Top

Signal → Service Transformation

- Raw ppm signals don’t solve the workforce problem.

- LDaaS (Leak Detection as a Service) interprets these alarms by:

- Filtering out noise (door openings, CO₂ cross-sensitivity, transient drift).

- Contextualizing alarms with charge size, asset history, service records, and operating state.

- Prioritizing dispatch so that technicians roll only when the leak is confirmed.

Compliance Clock Integration

- Each event is automatically logged, tied to the EPA repair clock or state-level requirements (e.g., CARB’s 14-day rule).

- LDaaS ensures that the repair timeline is initiated, tracked, and closed without the need for paperwork chasing.

Operational Benefits

Reduced truck rolls

Only confirmed leaks create work orders, helping keep the system running efficiently and minimizing unnecessary visits to each unit within the AC system.

Lower overtime costs

Early detection catches leaks before system stress triggers weekend failures.

Verified repair

Techs scan tags post-repair, with before/after readings uploaded to the cloud, ensuring every unit in the AC system is properly monitored and maintained.

Scope 1 Alignment

Every refrigerant event is converted to CO₂e emissions and updated against corporate climate targets (SB 253/SEC/CSRD).

Staying Ahead: Preventive Maintenance in the Age of Smart Detection

In today’s HVAC landscape, preventative maintenance is no longer just a best practice; it’s a strategic necessity for preventing refrigerant leaks and safeguarding the efficiency of air conditioning systems.

The rise of smart detection technologies has transformed how maintenance is performed, enabling technicians to spot potential issues before they become major problems.

Routine tasks like leak detection, coil cleaning, and system testing are now enhanced by automated systems and advanced sensors that continuously monitor system performance, flagging anomalies that could indicate a developing leak.

By leveraging these technologies, facility managers can take prompt action to address leaks, reducing energy costs and avoiding the operational disruptions that come with unexpected equipment failures.

Preventative maintenance not only extends the life of critical components like the evaporator coil and refrigerant lines but also helps ensure compliance with increasingly stringent environmental regulations.

It is also essential to regularly inspect and maintain the cooling unit to prevent issues such as mold growth inside the ductwork or freezing caused by low refrigerant levels, which can impact indoor air quality and system reliability.

Early detection and repair of refrigerant leaks minimizes refrigerant loss, protecting both the bottom line and the environment by reducing greenhouse gas emissions.

Ultimately, staying ahead with preventative maintenance means embracing a proactive approach; one that combines regular hands-on care with the intelligence of automated monitoring.

This synergy delivers optimal system performance, lower utility bills, and peace of mind, ensuring that air conditioning systems remain reliable, efficient, and environmentally responsible in the long run.

🚨 Stay ahead with smart preventive maintenance

Automated leak detection + routine care for lower costs, higher uptime, and cleaner operations.

Equipment Longevity and Energy Efficiency: The Long Game

Maximizing the lifespan of HVAC equipment is about more than just avoiding breakdowns; it’s about sustaining energy efficiency and minimizing costs over the long run.

Air conditioning systems that receive regular maintenance, including thorough leak detection and timely repairs, are far more likely to operate at peak efficiency year after year.

This not only reduces energy consumption and keeps energy bills manageable, but also delays the need for costly equipment replacements.

Preventative measures such as pulling a deep vacuum during installation or repair, ensuring proper refrigerant recharge, and routinely inspecting for leaks all contribute to equipment longevity.

By addressing refrigerant leaks promptly, building owners can prevent the kind of wear and tear that leads to premature failure, protecting both their investment and the environment.

Energy-efficient equipment doesn’t just save money—it also supports better indoor air quality and a more sustainable future.

In the long game of building management, prioritizing equipment longevity and energy efficiency through regular maintenance is a win-win for performance, cost savings, and environmental stewardship.

How It All Comes Together: AKO NDIR + LDaaS

The Hardware Edge

At the heart of AKO’s system is its NDIR sensor array.

Think of it like a lock-in amplifier for refrigerant molecules: instead of waiting for concentration spikes, it fires infrared light at precise wavelengths where refrigerants “vibrate.”

Each gas leaves a spectral fingerprint, like a barcode.

AKO’s detector is tuned to read those barcodes, and with signal processing that scrubs noise, it distinguishes a genuine leak from background chatter (humidity, dust, cleaning chemicals, CO₂ from forklifts).

From Sensor to Service

On its own, a sensor is just a number machine. The real power comes when those data streams are folded into Leak Detection as a Service (LDaaS). Every signal goes to the cloud, where it’s normalized against:

- The system’s refrigerant charge size.

- The recent service history (e.g., has refrigerant been added?).

- Store conditions (temperature swings, door openings, after-hours behavior).

That context is what makes it actionable.

Instead of just “there’s gas in the air,” the system says: “This alarm is real, here’s the asset ID, and it’s the kind of leak that worsens after closing time.”

The Relatable Geek Twist

If you’ve ever debugged code, you know the hardest part isn’t finding the bug—it’s filtering out the false positives.

That’s exactly the leap AKO made: turning a noisy analog signal into a clean digital decision. LDaaS is like having a senior engineer sitting on your shoulder, whispering: “Ignore that glitch, this is the real problem.”

So when you scale it, you’re not just dropping black boxes on a ceiling, you’re building an always-on, always-learning leak hunter that feeds technicians the right information at the right moment.

Closing the Cold War

The Cold War of leak detection (the decades of noise, false alarms, and reactive firefighting) is over.

The AKO patent marks a new chapter: one where machine learning listens beneath the noise, where compliance aligns with operational excellence, and where trust becomes the most valuable output of all.

As one technician put it after testing the system: “For the first time, the alarm told me something I didn’t know, and it was right.”

That is the signal. That is the story. And that is why this patent matters.

🚨 Close the Cold War of leak detection

AKO’s patented ML turns noise into trusted, actionable signals.