A New Refrigerant Playbook: The States Leading the Charge in Refrigerant Aligned Compliance

In an era where refrigerants have become the silent culprits of climate disruption, five states—California, Washington, Colorado, New Jersey, and New York—are reshaping the HVAC/R landscape.

The process of changing refrigerants from liquid to gas during boiling or evaporation, and vice versa during condensation, plays a crucial role in HVAC systems.

Each state has moved decisively to establish its own refrigerant management strategy, targeting the potent greenhouse gases hiding in plain sight within our cooling systems.

These strategies are underpinned by significant financial needs and finance strategies required for achieving climate goals, particularly in the Global South. But beyond the bans and thresholds lies a deeper story of climate ambition, regulatory maturity, and operational transformation.

The substantial financial resources required for refrigerant compliance highlight the need for significant private investment to contribute to this funding.

Table of Contents

ToggleThe Importance of Refrigerant Compliance

Refrigerant compliance is a cornerstone of effective HVAC system management, especially when climate commitments are at the forefront of corporate and governmental agendas.

Financial institutions and other stakeholders are increasingly scrutinizing businesses’ environmental impact, making it imperative for HVAC system owners and operators to align their refrigerant management practices with regulatory requirements and industry best practices.

Understanding the major components of the refrigeration cycle—such as the compressor, condenser, expansion device, and evaporator—is fundamental to achieving compliance and creating clarity in operational processes.

Knowledge of the risks associated with refrigerant leaks, improper handling, and disposal is equally crucial, as these can have significant environmental and health consequences.

From a risk management and governance perspective, non-compliance with refrigerant regulations can result in significant fines, reputational damage, and financial losses, as well as government involvement in your operations for many years.

Despite the numerous training programs available, many HVAC technicians are not adequately prepared for technological advancements and regulatory changes. Who can blame them for having many questions?

Simply understanding the requirements for one state can be challenging, and they don’t get paid to be compliance experts.

📌 Refrigerant compliance is a cornerstone of effective HVAC system management

Especially when climate commitments are at the forefront of corporate and governmental agendas.

The burden is on HVAC system owners and operators to create a robust compliance framework that includes developing policies and procedures, enforcement mechanisms, and team engagement.

Refrigerant Selection and Handling

Choose refrigerants that meet regulatory standards and handle them according to industry best practices to minimize environmental impact.

Leak Detection and Repair

Implement robust leak detection and repair protocols to reduce refrigerant emissions and prevent environmental damage.

Proper Disposal

Dispose of refrigerants in an environmentally responsible manner, adhering to all regulatory requirements.

Training and Education

Invest in training programs for HVAC technicians and other stakeholders to ensure they are knowledgeable about refrigerant compliance and best practices.

Record-Keeping and Reporting

Maintain detailed records of refrigerant usage, leaks, and repairs, and ensure timely reporting to regulatory authorities.

By focusing on these areas, HVAC system owners and operators can mitigate environmental risks, reduce operational costs, and build trust with clients, investors, and other stakeholders.

This proactive approach to refrigerant compliance not only supports long-term business success but also reinforces a commitment to sustainability and responsible business practices.

In conclusion, refrigerant compliance is a critical aspect of HVAC system management that demands a thorough understanding of the refrigeration cycle, adherence to regulatory requirements, and implementation of industry best practices.

By prioritizing these elements, HVAC system owners and operators can effectively manage risks, demonstrate their climate commitments, and achieve sustainable business growth.

California: The Pioneer of Precision and Policy Depth

California has long been at the forefront of environmental regulation, and its approach to refrigerant management is no exception.

The state’s proactive stance is driven by a commitment to reducing greenhouse gas emissions and promoting sustainable practices in the HVAC sector.

By setting stringent standards and providing a clear framework for compliance, California is setting a clear and identifiable business environment for the cold supply chain to both invest and deploy solutions.

The Refrigerant Management Program (RMP), overseen by the California Air Resources Board (CARB), is a testament to California’s dedication to precision and policy depth in addressing climate change challenges.

California’s efforts to reduce greenhouse gas emissions must continue to evolve as new climate-related products and regulations emerge.

Program Overview

- Registration Portal

CARB R3 - Regulation

Refrigerant Management Program (RMP) - Governing Body

California Air Resources Board (CARB) - Launch

2011 (updated through 2021 and beyond) - Applies to

Stationary refrigeration systems using > 50 lbs of high-GWP refrigerant (GWP > 150)

California’s leadership in refrigerant management is not just about setting rules; it’s about creating a culture of responsibility and innovation.

By encouraging the development of new technologies and practices, the state fosters an environment where businesses can thrive while meeting environmental goals.

This approach benefits the environment and enhances California’s businesses’ competitiveness on a global scale. As the state continues to refine its policies, businesses need to stay informed and engaged with the latest developments, ensuring they can adapt and comply with the evolving regulatory landscape.

Technical Requirements

Leak Inspection Frequency

| System Size | Inspection Frequency |

|---|---|

| ≥ 2,000 lbs | Monthly |

| 200 – 1,999 lbs | Quarterly |

| 50 – 199 lbs | Annually |

Leak Repair Deadline

- 14 days

Reporting Due

- March 1 annually (company-wide GWP report for retail food)

GWP Reduction Mandates

| By Date | Requirement |

|---|---|

| December 31, 2026 | Weighted average < 2,500 or ≥ 25% GHG reduction from 2019 |

| December 31, 2030 | Weighted average < 1,400 or ≥ 55% GHG reduction from 2019 |

The technical requirements under California’s RMP ensure that businesses remain accountable for their refrigerant usage and emissions.

Companies must accurately measure their refrigerant usage and emissions to comply with California’s stringent GWP reduction mandates.

By mandating regular leak inspections and setting ambitious GWP reduction targets, California is encouraging companies to adopt best practices and invest in more sustainable technologies.

These measures not only help reduce the state’s carbon footprint but also drive innovation within the firm as companies seek to meet these rigorous standards.

🚨 Don’t leave compliance to chance

Get in touch to learn how we can support your HVAC operations

In addition to the technical requirements, California’s approach strongly emphasizes education and training. By equipping HVAC professionals with the necessary knowledge and skills, the state ensures that they are capable of implementing the best practices in refrigerant management.

This educational focus helps to create a workforce that is not only compliant but also proactive in seeking out new solutions to environmental challenges. As the state continues to lead in this area, it serves as a model for other regions looking to enhance their refrigerant management practices.

Recent Legislative Layering (SB 253, SB 261, SB 219)

- SB 253 (2023) mandates Scope 1, 2, and 3 emissions disclosures starting in 2026 for companies with $1B+ in revenue.

- SB 261 adds climate-related risk reporting requirements aligned with TCFD.

- SB 219 harmonizes deadlines and eliminates duplicative reporting across agencies.

The recent legislative layering in California, through bills like SB 253, SB 261, and SB 219, reflects a comprehensive approach to climate governance. These laws are designed to enhance transparency and accountability, ensuring that companies are not only aware of their environmental impact but are also taking concrete steps to mitigate it.

By aligning with TCFD and harmonizing reporting requirements, California is fostering a culture of responsibility and foresight among businesses, encouraging them to integrate climate risk management into their core operations.

Compliance teams must ensure that their strategies align with the best interests of stakeholders, particularly in managing climate-related risks.

Compliance teams must actively engage with the firm’s climate strategies to ensure they are monitoring the progress of regulatory challenges and assessing whether sufficient advancements are being made towards commitments like net-zero pledges.

📌 In conclusion

California’s pioneering efforts in refrigerant management highlight the importance of precision and policy depth in tackling climate change.

By setting ambitious targets and fostering a culture of accountability, the state is not only leading the charge in refrigerant compliance but also paving the way for a more sustainable future.

As other states look to California for guidance, it is clear that a proactive and comprehensive approach is essential for achieving meaningful progress in the fight against climate change.

Federal Comparison

| Feature | EPA Section 608 | California RMP | SB Layer 219 |

|---|---|---|---|

| Leak Inspection Frequency | Only for ODS | Required for HFCs based on charge size | Not Applicable |

| Registration | No national registration | Mandatory via CARB R3 | Assurance required by 2028 |

| GWP Tracking | Not required | Central to policy | inside and outside the building |

| Emissions Disclosure | Not mandatory | 50 Lbs and Over | 100% regardless of size |

Washington: HVAC and Refrigeration Unified Under Rulemaking

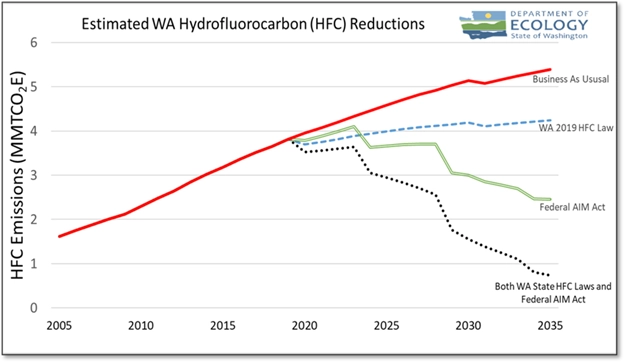

Washington’s proactive approach towards refrigerant management indicates a broader commitment to environmental stewardship.

The state is addressing a critical area of environmental stewardship by phasing out high-GWP refrigerants and incorporating HVAC systems into the regulatory framework.

The Department of Ecology’s ongoing rulemaking process under CR-101 aims to establish a robust structure for compliance, ensuring that businesses are well-equipped to meet the new standards.

This will likely involve collaborating with various stakeholders, including financial institutions, to secure the necessary investments to transition to more sustainable technologies.

The emphasis on mandatory leak inspections and repair tracking underscores the importance of maintaining system integrity to prevent harmful emissions. By expanding the scope to include comfort cooling systems, Washington is acknowledging the significant role these systems play in overall emissions. The anticipated compliance timeline provides businesses with a clear roadmap for adapting to the new requirements, encouraging early adoption of best practices and innovative solutions.

Program Overview

Regulation

HFC Prohibition (2020), Refrigerant Management via CR-101 (Rulemaking Underway)

Governing Body

Department of Ecology

Launch

2020 (phase-out); Rulemaking ongoing from late 2023 (CR-101)

Applies to

Refrigeration and HVAC/comfort cooling systems ≥50 lbs

Strategic investments in sustainable initiatives provide opportunities for businesses to innovate and lead in climate action.

📜 Stay ahead of Washington’s evolving regulations

Contact us to learn how we can help you navigate refrigerant compliance.

Technical Requirements

GWP Bans

The following refrigerants are being phased out in new equipment:

- R-134a

- R-404A

- R-410A

CR-101 Provisions (Proposed)

- Registration portal for large systems

- Mandatory leak inspections and repair tracking

- Comfort cooling systems included in the scope:

- Split systems

- RTUs (Rooftop Units)

- VRFs (Variable Refrigerant Flow)

Compliance Timeline: Rule expected mid-2025

Registration Deadlines

| System Size | Deadline | Fee |

|---|---|---|

| ≥ 1,500 lbs | March 15, 2024 | $150 one-time + $370 annual |

| 200 – 1,499 lbs | March 15, 2026 | $170 annual |

| 50 – 199 lbs | March 15, 2028 | No fee |

Leak Inspection Requirements

| System Size | Frequency | Start Date |

|---|---|---|

| ≥ 1,500 lbs | Monthly | January 1, 2024 |

| 200 – 1,499 lbs | Quarterly | January 1, 2026 |

| 50 – 199 lbs | Annually | January 1, 2028 |

Leak Repair

Within 14 days, with post-repair verification.

Leak Rate Notification Thresholds

| System Type | Leak Rate Threshold |

|---|---|

| Commercial refrigeration | 16% |

| Air conditioning | 8% |

| Industrial process systems | 24% (Notification to Ecology within 30 days) |

Additional Requirements

Recordkeeping

Retain all records for 5 years

ALDS Requirement

Systems ≥ 1,500 lbs by January 1, 2025

Annual Reporting

Required for systems ≥ 200 lbs

As Washington continues to develop its refrigerant management strategy, it remains crucial for companies to engage with the evolving regulatory landscape actively and work towards compliance.

This involves not only adhering to the new rules but also leveraging the opportunity to innovate and lead in sustainable practices.

By doing so, businesses can position themselves as responsible entities committed to mitigating climate change impacts, ultimately benefiting from the long-term sustainability of their operations.

📢 A New Framework for Solving Refrigerant Leaks

Leaks aren’t just technical failures—they’re trust failures. This webinar breaks down five key gaps and how to address them system-wide.

Federal Comparison

| Feature | EPA Section 608 | Washington CR-101 | Aim Act |

|---|---|---|---|

| Comfort Cooling Coverage + Refrigeration | Yes, but limited to ODS | Explicitly includes HVAC systems | Yes – for HFC phased |

| Leak Inspection | Yes, for ODS >50 lbs | Yes – but size differed from EPA; see above | Yes – by size |

| Registration/Reporting | None | Active | Digital platform pending |

| Equipment Sale Bans | Under the AIM Act by GWP | Mirrors and expands SNAP bans | GWP-based phased down |

Colorado: Threshold-Based Registration with Climate Accountability

Program Overview

State Regulations

Regulation 22 (5 CCR 1001-26), HFC Phase-Down Laws (HB19-1231, SB20-047)

Governing Body

Colorado Department of Public Health and Environment (CDPHE)

Launch

HFC bans phased in starting 2021; Regulation 22 fully effective in 2022

Applies To

Refrigeration and HVAC systems at facilities emitting ≥1,000 metric tons CO₂e annually

📌 Training programs are essential

to ensure that people involved in refrigerant management are knowledgeable and skilled.

Key Technical Requirements

System Threshold

Annual registration and reporting are required for facilities with ≥1,000 MT CO₂e emissions. This encompasses many commercial refrigeration and HVAC systems, particularly comfort cooling systems with large refrigerant charges.

Registration and Reporting

- Required under Regulation 22 for both emissions and inventory tracking.

- The first reports were due March 31, 2022 (calendar year 2021).

- Annual reports must be submitted by March 31 each year.

- Additional data from electric utilities is due by June 30 annually.

Leak Management

- Though Regulation 22 does not prescribe fixed leak inspection cycles, leak detection and emissions mitigation are mandatory for systems exceeding the threshold.

- CDPHE bases emissions calculations on the federal GHG Reporting Program (GHGRP) framework (40 CFR Part 98).

Sale and Installation Bans

- Colorado follows SNAP Rules 20 and 21, restricting high-GWP refrigerants in new equipment categories.

- Effective January 1, 2021, the use of certain refrigerants like R-404A and R-134a is banned in new supermarket systems, chillers, and vending machines.

GHG Inventory Integration

- Data submitted under Regulation 22 feeds into the state’s annual GHG Inventory.

- These inventories are used to track progress toward Colorado’s statutory climate goals under HB19-1261.

Sectoral Integration

- Comfort cooling systems, such as RTUs and split systems, are captured if the aggregate charge exceeds the 1,000 MT CO₂e threshold.

- The roadmap includes electrification, leak mitigation, and technician training programs to support decarbonization.

- The use of specific diagnostic and compliance tools is essential for meeting Colorado’s regulatory standards and effectively assessing system performance.

🧠 Understanding the principles of refrigerant management is crucial for compliance and environmental protection.

Regulatory Evolution & Timeline

| Year | Milestone |

|---|---|

| 2019–2020 | Adoption of HB19-1261 and Regulation 22; formal rulemaking initiated. |

| 2021 | Emission thresholds and reporting mechanisms finalized. |

| 2022 | Mandatory reporting began for calendar year 2021 emissions. |

| 2023–2025 | Roadmap reviews and policy updates will align Regulation 22 with Colorado’s broader GHG goals, including HVAC systems and refrigerant handling. |

Federal Comparison Table

| Feature | EPA Section 608 | AIM Act (Federal) | Colorado Regulation 22 |

|---|---|---|---|

| System Threshold | >50 lbs (ODS only) | No facility-level threshold; focuses on producers/importers | ≥1,000 metric tons CO₂e/year |

| Comfort Cooling Included | Yes (ODS only) | Yes | Yes, if emissions exceed the threshold |

| Registration Requirement | No | Pending for end users (except producers/importers) | Yes—for high-emission facilities |

| Leak Inspection Required | Yes (ODS only) | Yes | Required via emissions verification approach |

| Leak Repair Timelines | 30 days | Proposed under AIM updates | No fixed timeline; mitigation protocols required |

| GHG Reporting | No | Chronically leaky and annual reports proposed | Yes—annual GHG inventory aligned |

| Sale/Install Bans | Not enforced post-2017 | Yes—based on SNAP reinstatement + new bans | Required via the emissions verification approach |

Colorado’s Regulation 22 has matured into one of the most robust refrigerant policies in the U.S., integrating leak emissions, registration, GHG tracking, and enforcement mechanisms. Its inclusion of comfort cooling and its alignment with federal SNAP bans and GHG accounting protocols places Colorado in the vanguard of state-level refrigerant climate strategies.

New Jersey: Integrating Legacy Safety Standards with Modern Climate Governance

From Boiler Rooms to Carbon Accounting: A Dual-System Legacy

New Jersey’s refrigerant regulations are the result of an uncommon convergence: the layering of early 20th-century safety law with 21st-century climate policy.

While most states start from scratch when developing HFC rules, New Jersey expanded from an existing structure: the Boiler, Pressure Vessel, and Refrigeration Act (N.J.S.A. 34:7).

That law, originally passed in 1913, set annual inspection, licensing, and safety standards for refrigerant-containing systems, especially those operating under pressure or using flammable or toxic substances.

Understanding how the refrigeration cycle works is crucial for compliance and environmental protection.

The reality of climate change necessitates a robust regulatory framework that provides critical information and evolves with emerging challenges.

The modern regulations—N.J.A.C. 7:27E, formally adopted in June 2022—build on this foundation by incorporating greenhouse gas (GHG) emissions tracking and facility-level oversight under the state’s Global Warming Response Act (GWRA).

This fusion of safety-first infrastructure with climate-first governance created one of the most robust, multi-layered refrigerant management programs in the country.

Regulatory Milestones and Timelines

| Milestone | Date or Detail |

|---|---|

| 7:27E Rule Published | June 21, 2021 |

| Effective Date | July 2022 |

| Initial Registration Deadline | November 1, 2022 |

| First Reporting Period | July 1–Dec 31, 2022 |

| Annual Reports Due | April 1 for the prior calendar year |

Compliance with these regulations demonstrates respect for environmental standards and ethical business practices.

Each facility that meets the 50 lbs threshold must register its systems within 90 days of installation or by the November 2022 deadline if systems were already in place.

Registration lasts 5 years, while GHG emissions reports are submitted annually by April 1.

Refrigeration System Coverage and Definitions

The 7:27E rule applies to:

- Stationary, non-residential equipment (commercial, industrial, and cold storage systems).

- Systems containing ≥ 50 lbs of high-GWP refrigerants.

- Refrigerants are classified based on 100-year GWP values per IPCC AR4 and AR5 tables.

The rest of the systems not covered by these regulations must still adhere to general safety and environmental standards.

Commonly regulated refrigerants include:

- R-134a, R-404A, R-507A, and any blend with GWP >150.

Registration and Reporting Obligations

Registration

- Facility information: address, NAICS, tax ID, and contacts.

- System data: type, model, charge capacity, refrigerant type.

A dedicated compliance team is essential for managing registration and reporting obligations effectively.

Fee

- $400 per facility (valid for 5 years).

Annual Reporting

Due each April 1, facilities must report:

- Refrigerant additions, recoveries, purchases, and charges.

- System leaks, repairs, and full charge data.

- Inventory held or transferred for reclamation or destruction.

Facilities must maintain records for five years onsite, ready for inspection by NJDEP staff.

The Expanded Boiler Program

N.J.S.A. 34:7 + N.J.A.C. 12:90

Before 7:27E, refrigerant systems were already regulated, but strictly for engineering safety:

| System Type | Threshold |

|---|---|

| Toxic/flammable refrigerants | > 3 tons or > 6 HP |

| Non-toxic/non-flammable refrigerants | > 18 tons or > 36 HP |

| Systems with pressure-relief valves | Over 15 psig |

These systems must be:

- Registered with the Bureau of Boiler and Pressure Vessel Compliance.

- Inspected annually by a licensed insurance or state inspector.

- Inspected per ASHRAE 15, IIAR 2, IIAR 5, and IIAR 7 standards.

📌 New Jersey’s refrigerant regulations are the result of an uncommon convergence.

The layering of early 20th-century safety law with 21st-century climate policy.

Inspection Fees:

| Capacity | Fee (State Inspector) |

|---|---|

| 3–25 tons | $200 |

| 25–300 tons | $300 |

| 300+ tons | $400 |

Operators must also carry state licenses (fireman or engineer classifications) and display certificates on-site.

Federal Comparison Table

| Feature | EPA Section 608 | AIM Act (Federal) | NJ 7:27E + Boiler Act |

|---|---|---|---|

| System Threshold | >50 lbs (ODS only) | No end-user threshold | ≥50 lbs (7:27E), or >18 tons / 36 HP (Boiler) |

| Comfort Cooling Coverage | Yes (ODS) | Yes | Yes |

| Registration | No | Pending | Yes (5-yr, $400/facility) |

| GHG Emissions Reporting | No | Proposed | Yes (Annual, April 1) |

| Leak Repair Requirement | 30 days | Yes (for chronic leak systems) | Yes (via annual boiler inspections) |

| Recordkeeping | 3 years | Proposed | 5 years onsite (7:27E); via inspection logs (Boiler) |

| Sale/Install Bans | Not enforced post-2017 | Yes (GWP-based) | Yes (mirrors SNAP rules) |

Strategic Impact and Policy Rationale

New Jersey’s hybrid model does more than enforce—it educates, incentivizes compliance, and ensures operational continuity.

By embedding climate oversight within existing inspection regimes, the state reduces implementation friction, enhances enforcement, and prepares for a long-term policy arc independent of federal reversals.

Facilities that fail to comply face enforcement:

- Penalties up to $15,000 per violation per day.

- Non-renewal of boiler operation licenses.

- State-led inspections and repair mandates.

New Jersey’s approach demonstrates that legacy safety infrastructure, combined with climate-forward legislation, can result in one of North America’s most resilient refrigerant oversight regimes.

New York: A SNAP-Back Into Regulatory Leadership

Policy Context & Regulatory Leadership

New York’s 6 NYCRR Part 494 marks a defining shift in refrigerant governance—not merely a copy of EPA’s Section 608 or California’s RMP, but an integrated, forward-facing regulatory model built on enforcement, climate policy, and lifecycle management.

After years of regulatory drift at the federal level post-2017 SNAP rollback, New York snapped back with a sweeping rule that:

- Embeds refrigerants within the state climate law (CLCPA)

- Builds a full-lifecycle program from supply to service to system retirement

- Introduces corporate-level mandates on supermarkets and food retail operators

This is no longer about individual system compliance but operational climate accountability.

Program Overview

Regulation

6 NYCRR Part 494 – HFC Prohibitions and Reporting

Effective

January 9, 2025

Governing Body

NYS Department of Environmental Conservation (NYSDEC)

Applies To

Refrigeration, chillers, HVAC, and heat pump systems ≥ 50 lbs; reclaimers, suppliers, and supermarkets.

Scope and Coverage

System Threshold

≥50 lbs

Includes

Commercial refrigeration, AC systems, chillers, VRFs, heat pumps.

Residential Exemption

Applies only if installed in commercial operations.

Implementing these regulations requires coordinated work across various departments.

Technical Requirements & Timeline

| Application | GWP Limit | Effective Date |

|---|---|---|

| New retail refrigeration systems | >150 (100-yr) | Jan 9, 2025 |

| New chillers and VRFs | >700 (100-yr) | Jan 1, 2026 |

| Virgin bulk refrigerants | >2,200 (100-yr) | April 9, 2025 |

| Virgin R-404A and R-507A | — | Banned after Dec 31, 2025 |

| Virgin supply phase 2 | >1,500 (100-yr) | Jan 1, 2030 |

| Virgin supply phase 3 | >750 (100-yr) | Jan 1, 2033 |

| Final phase (all new systems) | >10 (20-yr) | Jan 1, 2034 |

Reducing GWP means lowering the environmental impact of refrigerants.

Leak Inspections, Registration & Reporting

| System Class | Charge | Frequency | Register By | Report By |

|---|---|---|---|---|

| Large | ≥1,500 lbs | Monthly or ALDS | June 1, 2025 | March 31, 2026 |

| Medium | 200–1,499 lbs | Quarterly or ALDS | June 1, 2026 | March 31, 2027 |

| Small | 50–199 lbs | Annual or ALDS | June 1, 2028 | Not Required |

Businesses must learn the new compliance processes to ensure timely registration and reporting.

Leak Repair

Immediate repair and verification are required.

Labeling

All systems post-Jan 9, 2025, must list refrigerant type, GWP, and reclaim status.

Recordkeeping

Required under Section 494-2.7 starting Jan 9, 2025

Reclaimed Refrigerants: A Hard Shift in Supply Chain Strategy

- Sale of virgin refrigerants > 2,200 GWP prohibited beginning April 9, 2025

- R-404A and R-507A phaseout extended to December 31, 2025

- Reclaimed refrigerant is allowed, but:

- Must be sourced from registered reclaimers

- Must be clearly labeled

- Annual reports due March 31, 2026

- Reclaimer registration is due June 1, 2025

This is the first statewide program that effectively forces a market shift to reclaimed refrigerants through GWP-linked sales restrictions.

Supermarket Refrigerant Program (SRP)

Applies to:

- Using ≥200 lbs of refrigerant per system

- Chains with ≥20 stores in NY or ≥100 nationwide

| Requirement | Deadline | Section |

|---|---|---|

| Annual Emissions Report | June 1, 2025 | §494-2.8(b) |

| Transition Plan (opt-in) | January 1, 2027 | §494-2.8(d) |

Supermarkets must either:

- Transition to refrigerants with GWP ≤ 10 (20-year) by 2035, or

- Maintain emissions below a system-wide performance target

Compliance with the program can provide significant benefits in terms of reduced emissions and operational efficiency.

Federal Comparison Table

| Feature | EPA Section 608 | AIM Act (Federal) | New York Part 494 |

|---|---|---|---|

| System Threshold | >50 lbs (ODS only) | Yes — monthly, quarterly, or annual, based on charge | ≥50 lbs (all HFCs) |

| Comfort Cooling Coverage | Yes (ODS only) | Yes | Yes — includes HVAC, VRFs, chillers, heat pumps |

| Registration Requirement | No | Manufacturers/importers only- user portal pending | Yes — by June deadlines based on the charge |

| Leak Inspection Requirement | ODS only, no set frequency | Proposed in updates | Yes — by June deadlines based on the charge |

| Leak Repair Requirement | 30 days | Proposed | Immediate + verified |

| GHG Reporting | No | Proposed for large facilities | Yes — Annual March 31 reports for ≥200 lbs systems |

| Sale/Install Bans | Not enforced post-2017 | SNAP bans reinstated | Yes — GWP thresholds phased through 2034 |

| Reclaimed Refrigerant | Allowed | Allowed – defined and go live 2028 | Allowed — with registration, tracking, and labeling |

Understanding the principles behind these regulations is crucial for effective compliance.

Strategic Insights: Why This Matters

Full Lifecycle Governance

New York is the first state to regulate refrigerants from:

- To corporate emissions targets (SRP)

- Import and sale (GWP restrictions)

- To operation and maintenance (RMP)

Stakeholders must ask critical questions to understand the full impact of these regulations.

This is a shift away from system-focused rules toward supply chain carbon management.

Structural Differentiators

| Feature | New York Part 494 | California RMP | EPA Section 608 + AIM Act |

|---|---|---|---|

| Reclaimer registration | Yes | No | No |

| Sales bans by GWP tier | Multi-phase through 2034 | Limited to refrigeration | SNAP-based bans only |

| Supermarket program with/ emissions | Yes | No | No |

| Lifecycle refrigerant tracking | Yes | Partial | No |

| Corporate transition planning | Required for large chains | Not required | Not applicable |

The reality of these regulations is that they require significant changes in business operations.

📣 NEW: Proposed Mandatory GHG Reporting for All Large Emitters

In addition to Part 494, New York proposed a new regulation in March 2024 requiring mandatory annual GHG reporting for large emitters across all sectors, including refrigerants.

🔗 Source: ESG Today – March 2024

Compliance with these reporting requirements demonstrates respect for environmental standards and ethical business practices.

This further confirms the state’s move toward enterprise-wide climate accountability, expanding beyond refrigerants into total facility emissions.

From Compliance to Climate Strategy

New York’s Part 494 doesn’t just regulate leaks—it redefines refrigerant governance as a climate imperative. It transforms leak detection into carbon accounting, reframes refrigerant sales as a regulatory gatekeeper, and elevates compliance to a strategic function across asset management, procurement, and sustainability.

The rest of the regulations must be understood in the context of broader climate strategies.

The result?

A state-led blueprint that could shape national refrigerant policy for years to come.

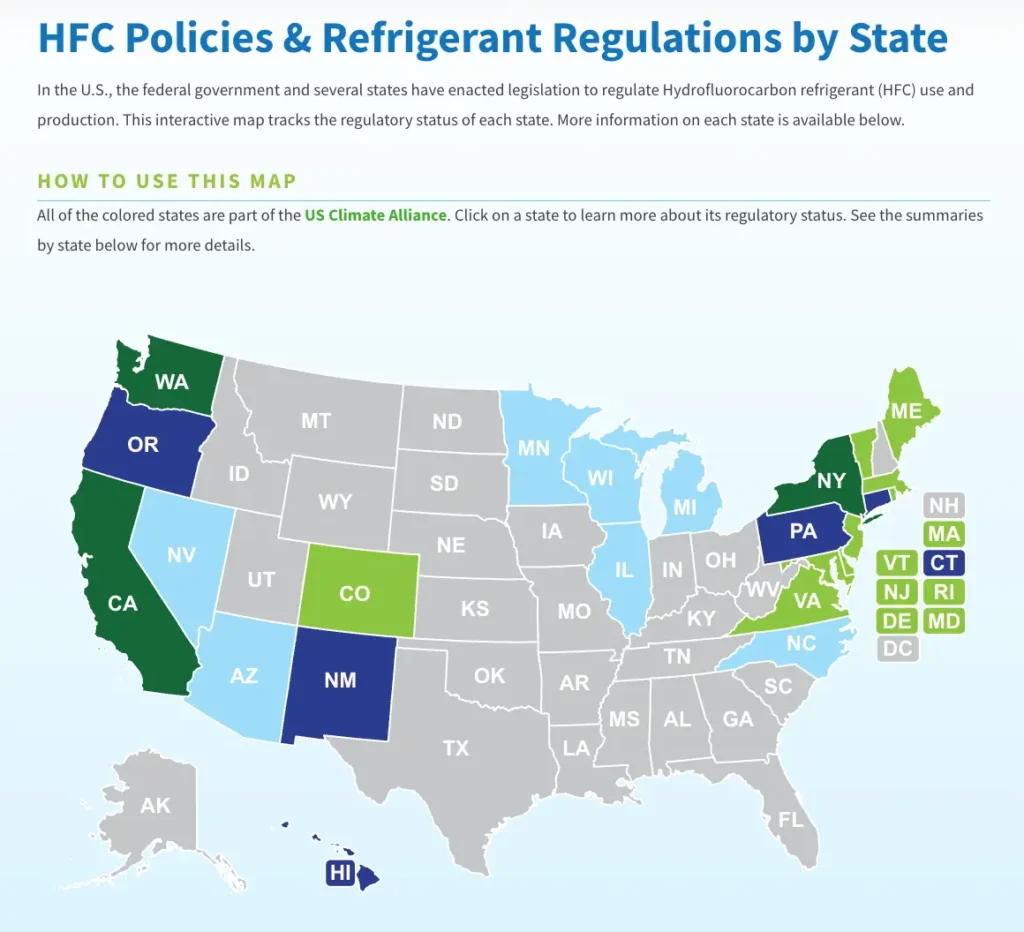

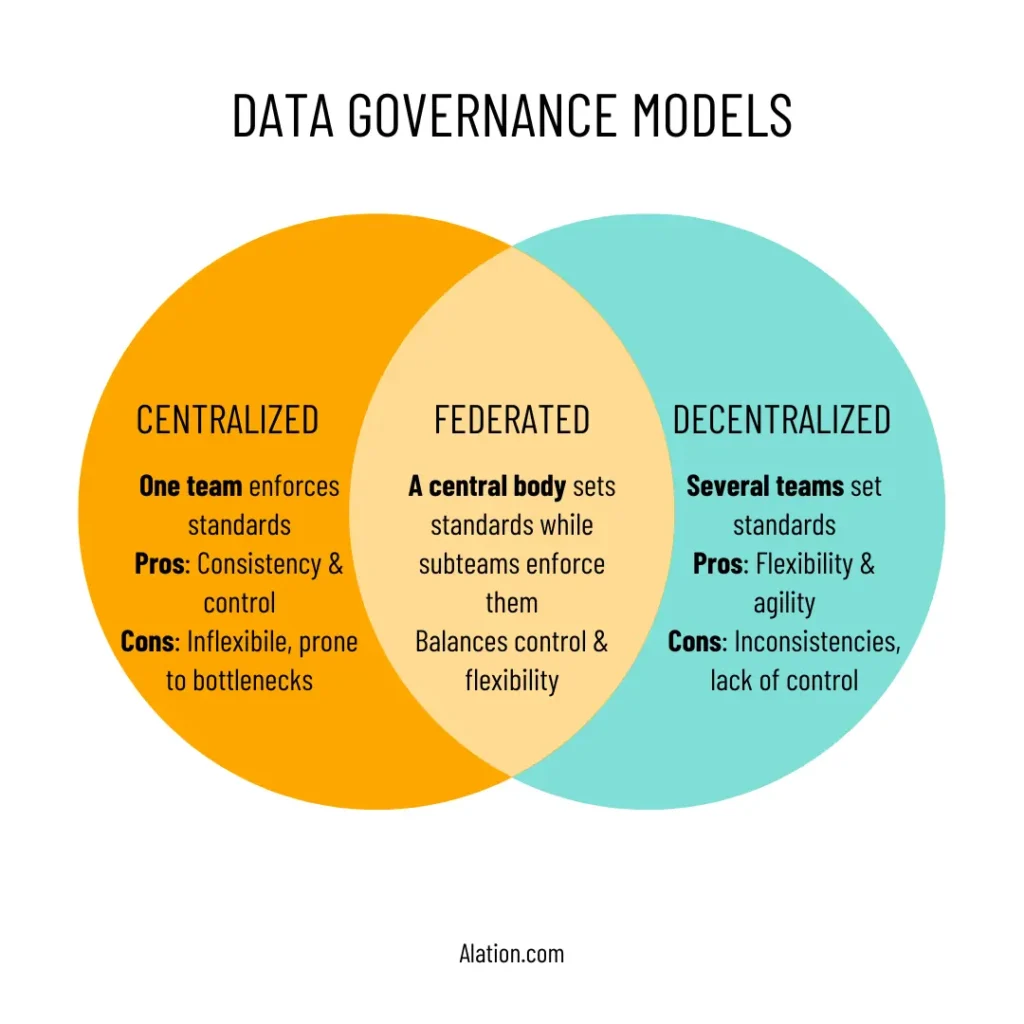

Final Takeaway: A Decentralized Future Demands Strategic Vigilance

What emerges from this evolving landscape is not a uniform national mandate but a decentralized, state-driven net of responsibilities that is growing more complex, not less.

While the federal EPA sets foundational rules under Section 608 and the AIM Act, the U.S. Climate Alliance states are increasingly writing the playbook for refrigerant compliance.

Each state—motivated by its own political will, environmental priorities, and regulatory capacity—has developed unique frameworks tailored to its electorate, economy, and enforcement infrastructure.

A dedicated compliance team is essential for managing the complexities of state-specific regulations, even if that team involves vendors.

This is not a temporary wave. These regulations are not in retreat.

Instead, they are expanding across refrigerant types, system categories, and reporting layers.

From California’s legislative depth (SB 253, 261, and 219) to Washington’s CR-101 inclusion of comfort cooling, and New Jersey’s state-wide portal mandates, local agencies are demonstrating both regulatory maturity and resilience.

Dedicated state budgets, emissions inventories, and legal independence from federal politics often support these programs.

The fragmented nature of this regulatory ecosystem presents operational challenges: refrigerant professionals and facilities managers must now navigate a disjointed, state-specific patchwork of bans, inspections, recordkeeping requirements, and emissions disclosures.

This demands more than routine compliance—continuous vigilance, proactive adaptation, and localized strategy.

But with that complexity also comes stability. Unlike federal programs that can be reversed with a change in administration, state-level policies are more insulated from political swings.

Local enforcement, stronger transparency mechanisms, and public pressure from regional climate goals all contribute to a growing permanence in these programs.

So while the road ahead may be bumpy and bureaucratic, it’s also where refrigerant policy is becoming most effective—and where innovation, accountability, and climate impact are converging.

Staying ahead of these decentralized mandates isn’t just smart business—it’s now a core competency for long-term operational and environmental performance.