Trust Gaps in Refrigerant Leak Detection, HVAC, and Refrigeration

Table of Contents

ToggleReversing 5 Trust Gaps in HVAC/R Leak Detection for Enhanced Compliance and Confidence

Eighteen months ago, I set out to better understand refrigerant leak detection.

I thought I would find some breakthrough technology to finally solve ac refrigerant leaks and refrigerant leaks, an issue that, depressingly, has remained stagnant for over 30 years.

AC/Refrigeration system refrigerant leaks remain a common and ongoing challenge in the industry. It was hard to believe that with so many advancements across industries, and more than a generation of innovation, all the new technology deployed, money invested, and time committed have amounted to almost no meaningful progress.

The HVAC/R industry is at a critical juncture regarding refrigerant leak detection. Beyond regulatory mandates, the escalating costs of lost refrigerant, equipment damage, and environmental impact necessitate a sophisticated, integrated approach.

Regular maintenance and professional service are essential to maintaining HVAC systems, AC systems, refrigeration, and AC units, preventing leaks, and ensuring reliability.

Early detection and professional intervention can significantly reduce repair costs by preventing major system failures.

Instead, I found owners and operators continuing to invest in new technology, yet getting little in return. Some people trusted these solutions momentarily, and then the trust collapsed.

My original thesis was that new tech was evolving and would finally solve the refrigerant leak problem.

I thought all I had to do was find the right solution, help deploy it across the U.S., and then move on to the next big issue: the massive, persistent labor shortage dragging the industry down for over 30 years (more on that later).

The first problem was that my original thesis wasn’t entirely correct.

📌 It turns out refrigerant leaks aren’t just a technology problem

They’re a far more nuanced challenge.

Leaking refrigerant, aka leaking Freon, can undermine the system’s efficiency and lead to trust gaps between stakeholders.

I still believe this problem is solvable and within reach.

But to make progress, we first need to understand why 30 years of effort, regulation, and investment have failed to fix the issue—and what it’s really going to take for new technology to overcome that legacy of failure.

While working at Trakref, we identified a pattern called phantom emissions—emissions that may or may not have occurred but are incorrectly recorded.

For example, a technician says he added 30 lbs of R-22 to your system, but only 24 lbs went in.

Still, you’re billed for the whole bottle because that’s how the pricing works. One story gets told, but the data reflects something else entirely.

This disconnect highlights one of the core trust gaps between owners, operators, and service providers—gaps fueled by missed signals, inaccurate records, and workflow breakdowns.

Another kind of phantom emission is the small leak no one can find—until it becomes catastrophic. A few ounces lost here and there may seem minor, but over time, they compound, stressing the system until it shuts down.

By then, it’s too late to be proactive.

The tools and data are too isolated, with siloed tools and isolated fixes, to truly reverse these trust gaps.

Preventive measures, such as regular visual inspection, electronic leak detection, and electronic leak detector tools, are critical for early leak identification and prevention. Most techs have a leak detector and are familiar with the routine.

But that’s not the problem; the issue is much more nuanced, and it turns out that we need to embrace the multifaceted realities of leak detection across diverse, complex, and often aging systems.

🚨 Webinar Alert

How to Reverse 5 Trust Gaps in HVAC/R Leak Detection? With Ted Atwood, Co-Founder of Carbon Connector

Only then can we build durable trust that leads to measurable results.

For decades, we have been using all kinds of tools called sniffers. These are technically advanced manual methods, such as electronic, ultrasonic, and fluorescent leak detection.

The challenge is that these HVAC/R systems run without supervision when we are not leak checking, so we need to make sure we are checking the right things at the right time and documenting what we do well.

The intermittent checks are usually limited to one day or even a few hours, and the leak might not be prevalent at that time; it might be a leak that happens only when specific criteria, activities, or weather are present.

Compare this to the hundreds and thousands of fittings that comprise the typical system in Data Centers, Grocery, and throughout the Cold supply Chain.

Success in modern leak detection is an art supported by science, technology, and a deep understanding of system behavior. Licensed technicians play a crucial role in ensuring that leak detection and repairs are performed safely and in accordance with regulations.

Let’s delve into the essential components needed to bridge these trust gaps.

The Playing Field: Understanding Refrigerant Leaks and Their Causes

When refrigerant escapes from the system, it reduces the cooling capacity, leads to increased energy bills, and, if left unchecked, can result in costly repairs or even system failure.

The root causes of refrigerant leaks are varied, but they most often stem from the natural wear and tear of AC components, including low refrigerant corrosion of parts, physical damage to refrigerant lines, and poor installation practices that leave joints and connections vulnerable.

Corrosion is a particularly frustrating culprit, as it can eat away at coils and other metal components over time, creating small holes that allow refrigerant to escape – pinholes that are not visible to the human eye. Physical damage—whether from accidental impacts, vibration, or environmental factors—can also compromise the integrity of refrigerant lines and frozen evaporator coils.

Even something as simple as improper cleaning or maintenance can inadvertently cause or conceal leaks.

Why the Old Fixes Aren’t Working?

Visual checks, sniffers, sensors—they’re not enough. Learn how to rethink leak detection and rebuild stakeholder trust.

The Playing Field

Advanced Automatic Leak Detector Technologies (The Sentinels of Detection)

Effective leak detection hinges on the capabilities of the tools at hand. While older methods like soap bubbles still have their place for large, obvious leaks, modern HVAC/R demands precision and sensitivity.

The bubble test can also help identify smaller leaks by producing microbubbles.

Advanced diagnostic tools such as UV dye are also used to locate refrigerant leaks accurately. In addition, electronic leak detection and the use of an electronic leak detector are essential for pinpointing the exact location of refrigerant leaks, especially when troubleshooting small or hidden leaks within the system.

The core distinction lies between continuous, fixed monitoring systems and portable, handheld devices, each serving a vital, distinct purpose.

Continuous Leak Detection: Automated Leak Detection Systems (ALDS) / NDIR Style

ALDS, like those made and deployed by AKO, employ Non-Dispersive Infrared (NDIR) technology and act as silent sentinels.

These stationary, permanently installed systems are designed to monitor large areas like machinery rooms, cold rooms, or supermarket display aisles 24/7.

How NDIR Works

NDIR sensors emit an infrared (IR) light beam through a gas sample chamber. Refrigerant gases absorb specific wavelengths of this IR light. By measuring the reduction in light intensity at that specific wavelength, the sensor can precisely determine the concentration of the refrigerant in the air.

Advantages

NDIR offers high selectivity (detecting only the target gas, significantly reducing false alarms from other ambient gases), excellent stability with minimal drift over time, and a broad detection range from very low parts per million (PPM) to higher concentrations.

These systems are invaluable for continuous monitoring, providing early warning signals of general refrigerant presence, supporting compliance reporting, and alerting personnel to potential safety hazards.

They also contribute to maintaining the system’s efficiency by enabling early detection and repair of leaks.

Application

Prominent manufacturers like AKO provide NDIR-based gas transmitters designed for continuous monitoring in critical areas within supermarkets, cold rooms, and compressor rooms.

Their systems often integrate seamlessly with building management systems (BMS), offering real-time alerts and comprehensive data logging crucial for proactive maintenance, trend analysis, and regulatory compliance.

📢 A New Framework for Solving Refrigerant Leaks

Leaks aren’t just technical failures—they’re trust failures. This webinar breaks down five key gaps and how to address them system-wide.

Think of each unit as a Little Chemical Reactor

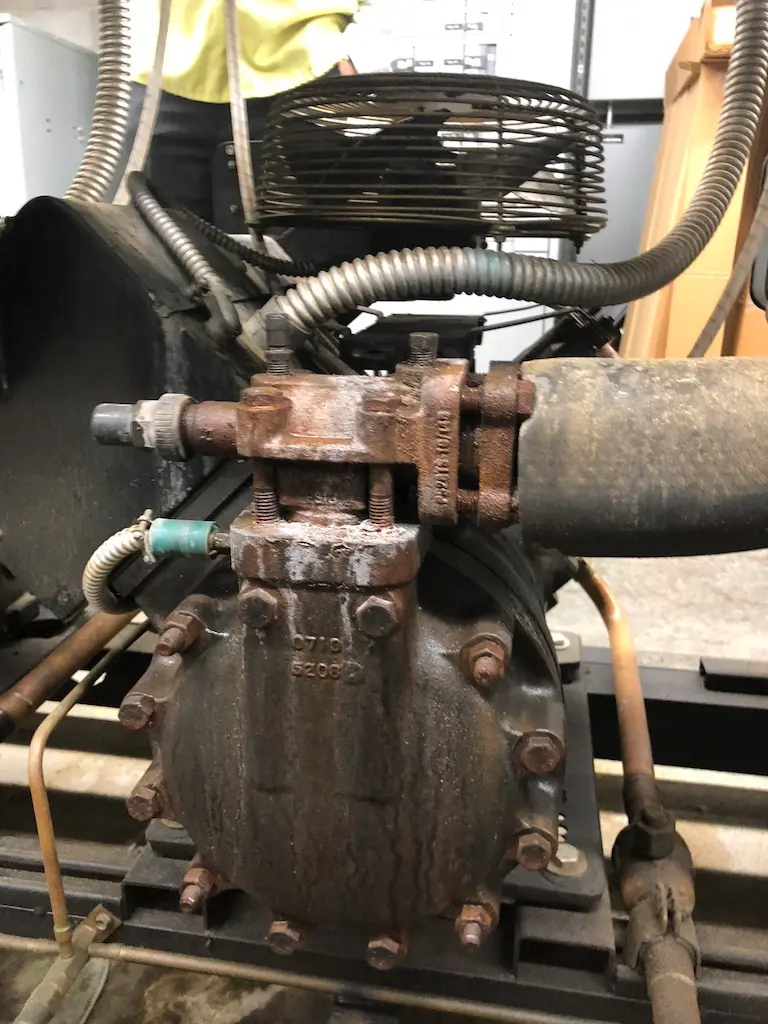

HVAC/R systems function like miniature chemical reactors—enclosed environments where copper, brass, aluminum, oils, plastics, polymer seals, extreme temperatures, and complex refrigerants interact constantly.

Even under normal operation, these conditions can generate acids and cause corrosion.

Leaks often begin as microscopic breaches in the evaporator coil, condenser coil, or refrigerant lines—critical components where pressure and materials meet.

These small leaks, including small refrigerant leaks, commonly cause refrigerant loss and can be difficult to detect without the right tools. That’s why detailed, methodical inspections are essential.

A thorough visual inspection should be performed to identify obvious signs of leaks, such as oil spots or damaged components.

Additionally, pressure test procedures can be used to pressurize the system and monitor for a pressure drop, helping to pinpoint hidden leaks and ensure system integrity.

1. The Foundational Challenge: Identifying Phantom Emissions and Missed Signals

The first two trust gaps are deeply intertwined:

- Phantom emissions (small, persistent, often invisible leaks)

- Missed signals (overlooked indicators of these leaks).

These gaps persist due to limitations in traditional methods, human error, and the sheer complexity of modern HVAC/R systems.

To reverse these, we must rely on a variety of technologies and rigorous practices.

Common signs of refrigerant leaks include:

- Oil spots on or around AC or refrigeration components,

- Bubbling sounds from the refrigerant line,

- Ice buildup on coils or lines,

- Your butter and ice cream are melting,

- The C-suite is getting uncomfortable,

- Unexplained increases in energy bills

Monitoring refrigerant levels during routine checks is also crucial for early detection of leaks.

These indicators help technicians and homeowners identify potential leaks early, preventing further damage and increased energy consumption.

Refrigerant leaks can also lead to poor indoor air quality, a sudden spike in energy bills, and reduced system efficiency.

When diagnosing leaks, technicians often use pressure test procedures and monitor for a pressure drop to identify hidden leaks. Some newer techs will target the liquid level.

However, these indicators are not always accurate; they can be misleading, and their root cause can be misunderstood.

Missed signals can occur if a thorough visual inspection is not performed or if preventive measures are neglected. This allows leaking refrigerant to go undetected and cause ongoing problems.

The problem never solves itself, unless it loses its entire charge, and then there is nothing left to leak – mission accomplished?

Ready to stop refrigerant leaks before they cause downtime?

See how next-level efficiency is just one integration away.

2. Portable but Not Perfect: The Realities of Handheld Refrigerant Leak Detectors

Handheld Portable Leak Detectors: The Unsung (and Often Mishandled) Heroes of HVAC/R

While Automatic Leak Detection Systems (ALDs) offer continuous monitoring, it’s the handheld portable leak detector that technicians wield to pinpoint the precise location of a leak.

These are specialized, mobile tools, not permanently installed like ALDs, designed for focused, on-site inspection.

Electronic leak detectors and advanced methods of electronic leak detection technologies are essential for accurately identifying the exact location of refrigerant leaks, especially in complex systems.

However, despite their critical role, their accuracy and reliability often face significant challenges.

The Unseen Flaws of Portable Detectors

Generic, Not Precision

Unlike the fixed, precise nature of ALDs, handhelds offer a more generic leak detection, scanning for the presence of many leaks rather than pinpointing tiny, specific refrigerant anomalies in a controlled environment.

Maintenance Matters (and is Often Missed)

Like their ALD counterparts, these tools are highly sensitive instruments that require regular maintenance. Their sensor tips, in particular, need filters to prevent contamination, a crucial step often overlooked.

The “Toolbox Tumble” Effect

Designed for portability, these devices frequently endure rough handling. They are often put into a toolbox, swung around, and banged, significantly impacting their performance and accuracy, contributing to false alarms and untrusted results.

Wrong Gas

Leak detectors are good at a few things, but not all things. Recently, I was working with a tech who insisted he checked and the leak was not present, but we looked at the detector he was using; it was 13 years old and not set for the refrigerant he was testing

How They (Should) Work

A Look at Sensing Technologies

Handheld detectors utilize various sensing technologies, each with its own strengths and sensitivities:

Heated Diode Detectors

Common and highly sensitive to halogenated refrigerant gases. While excellent for detecting small refrigerant leaks, their sensors demand frequent replacement and are prone to sensor fouling and false positives if not maintained.

Infrared (IR) Detectors

Similar to NDIR ALDs, these draw air samples and use IR light absorption. They are generally accurate, less prone to false positives from other gases (like cleaning solvents), and boast longer-lasting sensors.

Ultrasonic Detectors

They ”listen” to the high-frequency sounds of gas escape from pressurized systems and are useful in noisy environments but may miss very small or low-pressure leaks.

Corona Discharge Detectors

They identify gas presence by changes in an electrical field and offer sensitivity but are susceptible to false alarms from non-refrigerant gases.

Their Indispensable, Yet Challenged, Role:

Pinpointing Leaks

It is crucial for precisely locating the source. ALDs of any type will tell you have a leak, and then the real work begins: pinpointing the exact location, and that’s when these tools are required.

Safety & Compliance

Essential for prompt repair, minimizing harmful refrigerant release, and meeting regulatory requirements.

Reversing Trust Gaps

They are vital for technicians to confirm continuous monitoring alerts, conduct routine maintenance checks, and perform thorough post-repair verification.

They bridge the gap between identifying a potential problem (ALDs) and resolving it definitively, but only when properly maintained and their limitations are understood.

3. Beyond the Obvious: Why Leak Detection Isn’t Just Leak Repair

Unraveling the Diagnostic Labyrinth

The overfill dilemma often mimics leaks; technicians might top off systems based on readings, but it could be a seasonal load change.

New systems, especially those commissioned in cold months, may appear low on charge in warmer weather, leading owners to misinterpret normal adjustments as leaks and trigger unnecessary warranty claims.

Precise recharging and meticulous monitoring are crucial to avoid misdiagnosis.

Then there’s the insidious “many leaks” problem, where one repair leaves others undiscovered.

This includes conditional leaks, which only emerge during specific cycles like defrost or under peak pressure, eluding detection without deep system understanding.

The “straw-and-camel” issue refers to small, chronic leaks across miles of tubing and joints in older commercial systems that, while individually minor, accumulate into significant emissions and performance failures.

Thoroughly addressing all sources is essential for efficiency.

Confronting Structural Complexity and Detection Limits

Compounding these issues is the structural complexity of the installed base, with facilities housing diverse, decades-old equipment. This creates vast systems with unpredictable leak behaviors and countless failure points.

Even detection tools have limits: outdoor AC/Refrigeration leaks dilute rapidly, becoming nearly invisible to ambient monitors.

At the same time, handheld detectors are directional tools prone to missing slow leaks without proper profiling. Pressure tests and diligent monitoring can help identify hidden leaks.

Ultimately, effective leak management demands more than just tools—it requires situational awareness, technical patience, and cross-seasonal insight.

📌 It’s about understanding the system as a whole to earn back confidence

One verified fix at a time.

4. When Precision Slips: Addressing Sensor Drift and Calibration in Leak Detection

Leak detection systems need to be more than just installed—they need to be trusted. Over time, even high-end sensors can drift. If a system is only 80% accurate, that’s not coverage—it’s a liability.

Periodic check-ins aren’t just maintenance—they’re how your system says, “I’ve got your six.”

Spot issues early, verify performance, and stay mission-ready.

Understanding Sensor Drift and Calibration Concerns

These sophisticated detection devices, particularly continuous monitoring systems operating 24/7, are precision instruments.

However, like any precision tool, their accuracy can drift over time due to environmental factors, sensor degradation, or continuous operation.

If these devices aren’t consistently accurate, their readings can become unreliable, leading to false positives or, more dangerously, missed leaks, eroding confidence in the technology itself.

Rigorous Calibration Protocols

Implement strict, scheduled calibration procedures for all leak detection equipment – both handheld and fixed. This includes “zeroing” devices regularly and ensuring they are calibrated against known refrigerant concentrations. Understand that continuous operation means these devices are constantly exposed to varying conditions, making regular calibration even more critical.

Understand Calibration Effectiveness

Don’t just calibrate; understand how effective the calibration is.

Verify the device’s response after calibration using test gases or controlled leaks to ensure it’s performing within specified tolerances.

Document calibration results to track performance over time.

Automated Diagnostics for Fixed Systems

Leverage the internal diagnostic capabilities of permanent refrigerant monitoring systems.

Many modern systems can self-check sensor health and alert technicians to potential drift or malfunction, prompting a proactive service call before accuracy is compromised.

Consider routine sensor replacement schedules as part of preventative maintenance for continuous monitors.

5. It’s a Poor Craftsman Who Blames His Tools—Leak Detection Requires a Tiered Team Effort

True leak detection doesn’t start with a sensor and doesn’t end with a tech on-site. It begins with coordination—with people—with a system of subject matter experts reviewing data, spotting patterns, running diagnostics, and using technology as a multiplier, not a crutch.

The most effective operations I’ve seen aren’t just reactive but layered. A first tier of experts works behind the scenes, interpreting data streams and system trends. They catch the early signals, validate them, and decide whether a dispatch is necessary. That triage prevents wasted time, repeat visits, and the kind of guesswork that turns minor issues into significant costs.

Then comes the field response: qualified technicians who show up with tools and context.

They know the site history, the last charge, and the failure patterns.

They’re part of a feedback loop that connects real-world conditions to performance analytics, closing the gap between data and decisions.

Yes, tech matters.

However, the people behind the platform, the SMEs who verify alerts and flag anomalies before they trigger service calls, drive real results. This is a layered defense against system failure—and it works.

Leak detection, done right, is not a single action. It’s a coordinated operation—a mix of planning, insight, and accountability. The best HVAC/R partners don’t just bring equipment; they deliver effective orchestration.

Close the Trust Gaps in HVAC/R

Decades of tools, tech, and investment—yet refrigerant leaks persist. Join us to uncover why, and what it really takes to move forward.

Maintenance Matters—But So Does Communication

Routine tasks like cleaning coils are critical to HVAC/R performance, but they can inadvertently cause or conceal damage if not properly communicated. For instance, if a refrigerant leak appears after a coil cleaning, was the technician aware of the recent service? That context can significantly impact inspection accuracy.

When done thoughtfully and with full visibility across service teams, preventive maintenance reduces repair costs and helps prevent leaks. A well-maintained system performs more efficiently, especially during high temperatures, when stress on components increases. Neglecting these practices leads to higher energy consumption, elevated bills, and reduced indoor comfort.

By integrating advanced technology, deep operational understanding, and a proactive management philosophy to reverse these five trust gaps, considering environmental conditions, the HVAC/R industry can significantly enhance compliance, improve operational efficiency, and build greater confidence among all stakeholders.

📌 This shift is not just about avoiding penalties

It’s about fostering a more sustainable, reliable, and profitable future for HVAC/R.

Trust Is the Critical Leak

We have sensors that detect in parts per billion, dashboards, alerts, and AI. But we still don’t know where the refrigerant went—or how it got out.

Eighteen months ago, I set out to find the breakthrough that would finally solve the air conditioning system refrigerant leaks. With decades of innovation behind us, surely the problem had been solved by now. But what I discovered wasn’t a technology issue—it was far messier.

We don’t have a leak detection problem. We have a trust problem that leaks from every joint in the system.

“A new hammer won’t build you a better house – but it might lead to less fatigue”

At Carbon Connector, we are coming to the conclusion that Leak detection isn’t a one-person job—it’s not even a tool-driven job. It’s a trust-driven operation, and trust isn’t built by technology—it’s built by behavior.

Webinar: From Reactive to Reliable

Stop chasing leaks. Start preventing them. Discover smarter strategies for detection, documentation, and durable outcomes.