Earth Day 2025: From the Field to the Frontline. A Year of Real-World Progress in Leak Detection, Tagging, and Operational Accountability

Earth Day has been celebrated annually since 1970, marking a day dedicated to environmental protection and awareness. In 2015, a pivotal year for the environmental movement, the global theme of Earth Day focused on leadership in environmental advocacy, which was the kick-off of the year for Trakref, one of my recent commitments to that stewardship. Major initiatives were launched in preparation for critical climate negotiations in Paris, setting a context where the actions taken during this time were seen as essential for the future trajectory of environmental policies.

In the 1990s, Earth Week played a crucial role in mobilizing people for environmental actions leading up to Earth Day, showcasing grassroots organizing efforts and various events that raised awareness globally, such as tree plantings, park and river cleanups, and real grassroots engagements.

The significance of Earth Day has only grown over the decades, with more people and organizations participating in activities aimed at promoting sustainability and protecting our planet. The alarming state of environmental issues, such as climate change and pollution, underscores the urgency of these efforts. During Earth Day’s early days, decisions about its organization and branding significantly influenced the environmental movement, reflecting a broader vision for environmental awareness and activism.

One year ago, I wasn’t in a boardroom. I was in Australia.

I was not attending a keynote or giving a talk. I was on the ground, inside mechanical rooms, reviewing equipment logs and meeting with the people responsible for keeping buildings running. I was there to see how teams effectively operate their building’s systems to achieve carbon goals and translate them into actual operational outcomes.

In Australia, I saw how teams linked building automation systems with fault detection and diagnostics (FDD) to find refrigerant issues early, reduce service costs, and relieve pressure on overextended technicians. They integrated systems with analog outputs to connect to central control systems, enhancing detection functionalities and providing versatility and redundancy for different sensor configurations or as backups. Their priority wasn’t innovation for its own sake—it was effectiveness.

Later, I traveled to Spain, where grocers had directly embedded refrigerant leak detection systems into their maintenance workflows. They weren’t running pilot programs—they were running stores, confident that their systems would alert them to leaks before they became emergencies.

Detecting leaks is crucial for maintaining operational efficiency. It ensures that issues are identified and addressed promptly, preventing costly downtime and repairs.

🛠️ Less Downtime. More Earth Time.

At every turn, the message was the same:

This wasn’t an aspirational journey. It was a utility-driven one. Because the real work of Earth Day doesn’t happen in annual reports—it happens in daily decisions.

Table of Contents

Toggle🌱 Why We Took This Journey: A Search for What’s Already Working

We didn’t go looking for the next big idea. We went looking for grounded answers to practical questions:

- How do we reduce refrigerant emissions without adding unnecessary complexity?

- How do we meet EPA and state requirements without creating another burden for already stretched teams?

- How do we make building automation and refrigerant data work automatically and at a lower cost?

These solutions often include advanced gas detection systems that ensure compliance with safety regulations and provide effective monitoring solutions tailored to specific environments.

These solutions were all working in their markets, and it was common for the user bases to customize for specific applications in different industries, such as optimizing HVAC systems in commercial buildings or ensuring compliance in industrial refrigeration. For example, an FDD system in HVAC operations can identify inefficiencies, demonstrating the practical application of the technology in improving system performance. We believed there was a core of prescriptive (well-defined) insights with universal applicability. Our thesis was that by improving efficiency, these solutions help save money while maintaining high standards.

This wasn’t about blue-sky thinking. It was about translating real problems into working solutions. This led to the platforms and approaches we now support, each based on the idea that

Operational systems should serve people, not overwhelm them.

Future-Proof Your Facilities, Protect the Planet

📜 History and Background – not what you’re thinking

Earth Day, an annual event, is rooted in the 1960s and 1970s environmental movement. The first Earth Day was held on April 22, 1970, and was organized by Senator Gaylord Nelson. Since then, Earth Day has become a global event, with millions participating in activities promoting environmental literacy, sustainability, and climate change awareness. The Earth Day Network has played a crucial role in promoting environmental issues and providing solutions to address them. Building automation and management systems have also become essential in reducing energy consumption and promoting energy efficiency in buildings.

Understanding the Roots of Earth Day and Its Evolution Over Time

Earth Day began with urgency, not branding. In 1970, it launched as a protest, a direct response to oil spills, smog, and toxic waste. Spearheaded by Senator Gaylord Nelson and propelled by student-led teach-ins, it marked the beginning of the modern environmental movement. It wasn’t polished. It wasn’t orchestrated. It was a demand for accountability – it was truly a grassroots effort, but the secular movement was not attracting a broad audience at the time.

But over time, Earth Day evolved from a call to action into a calendar event.

Now, it often looks more like a press release than a platform for change.

And while history matters, understanding the roots of Earth Day has nothing to do with building a movement capable of solving today’s problems.

Because this isn’t about awareness anymore.

This is about resiliency.

“The polish is off the shine.”

That’s how one operator put it to us this year after watching yet another Fortune 500 company quietly walk back its environmental goals. And he’s not wrong.

In 2024 and early 2025, we saw dozens of high-profile rollbacks—delayed net-zero targets, paused Scope 3 initiatives, and slashed ESG budgets. The message is clear: when pressure builds, the aspirational fades.

But there’s one thing companies aren’t walking back:

Operational resiliency

Because resiliency—the ability to withstand disruptions, prevent failure, and respond quickly when conditions change—isn’t a climate issue. It’s a business one.

And the companies that get that? They’re not waiting for policy wins.

They’re investing in tools that:

- Support the workforce, not just compliance departments

Because at its core, resiliency isn’t abstract. It’s practical.

It’s what happens when a technician gets an early warning before a coil freezes.

It’s when a store stays online through a heatwave because a leak was caught early.

It’s when the person in the field has the information and the authority to act without delay.

We don’t build that resiliency in conference rooms.

We build it:

- In mechanical rooms

- On rooftops

- In truck cabs at 6 a.m., reviewing service logs

- In back-of-house spaces, no one visits until something breaks

“We don’t need more goals. We need systems that hold up under pressure.

That’s what resiliency really means.”

If Earth Day is to matter in the years ahead, it must stop reaching for inspiration and start reinforcing infrastructure.

Let’s focus on the people already holding the line, despite labor shortages, rising costs, and systems stretched beyond their limits.

Because they’re not here for slogans.

They’re here to solve problems.

And if we give them the right tools—tools that prioritize resiliency, usefulness, and accountability—we won’t just keep our promises.

We’ll build a workforce, a market, and a movement that can’t be rolled back.

🌍 Environmental Challenges

The Real Work of Earth Day Doesn’t Happen in Boardrooms

It happens in the back of a truck, a basement, or a rooftop

Let’s be honest about where we are.

Earth Day has been used for too long as a stage for high-level pledges, glossy infographics, and global declarations. While the original vision, launched in 1970 as a grassroots environmental protest, was rooted in urgency, action, and grassroots, today, it’s often reduced to recycled slogans and abstract goals.

But understanding the history of Earth Day does nothing to solve the problem we face now.

We must get past the aspirational narratives and get grounded if we want real progress. The people who are positioned to solve refrigerant leaks, reduce emissions, and keep critical systems running aren’t asking how to align with a global movement. They’re thinking about:

- Mortgage payments / Car insurance / their kid’s sports / getting home in time for dinner

These people keep the industry running—they’re more essential now than ever. They ensure the building’s systems and technologies function efficiently, from fault detection and diagnostics (FDD) to utilizing its data network for automation. Maintenance staff are crucial in implementing these proactive measures, ensuring that potential issues are addressed before they cause significant downtime or damage.

We will miss the moment if we keep designing systems and strategies to appeal only to those with lofty climate goals or white-collar job descriptions. Because the solutions don’t come from PowerPoints or webinars. They’re being built:

- In the front seats of trucks

- In mechanical rooms buried in basements

- On rooftops in 90+ degree heat

- In conversations between a technician and a store manager at 7 am before the first customer walks through the door

Proper controls in energy management systems are crucial for optimizing building performance and reducing energy waste. And that’s where the real Earth Day needs to live.

🛠️ Less Downtime. More Earth Time.

Environmental Literacy and Awareness

Bridging the Gap Between Knowledge and Action

The challenge today isn’t a lack of information. It’s a lack of translation—getting information out of white papers and into work orders. And that’s where environmental literacy needs a reboot. It’s hard for any of us to identify with something so lofty as saving the world when mortgage and car payments are due.

We’ve seen firsthand that most people already care. They want to do the right thing. But what they’re lacking isn’t motivation—it’s tools that align with how they work. Innovative building technologies can enhance our environmental work lives and yield real, meaningful results in climate action, but one without the other is a failure.

That’s why we’ve launched what we call the Refrigerant Leak Project.

This isn’t a symbolic campaign. It’s a hands-on initiative focused on:

- Delivering real-time leak detection through proven sensor technology (getting beyond the 4% effectiveness of existing leak tracking)

- Simplify EPA and state regulations so they are not so complicated

- Empowering teams to use building automation systems and fault detection and diagnostics (FDD) not just for reporting but for operational decision-making

“The goal isn’t just to understand what’s wrong. It’s to build the capacity to fix it before it breaks something bigger.” We believe that environmental literacy must evolve from knowing what’s wrong to knowing what to do about it, right now, with the systems in place.

That’s why the tools we’ve built—BARLO, Watchguard, and Tag Wizard—are designed for the realities of the job:

- Minimal friction

- Instant visibility

- Outcomes that matter to both compliance and performance

No training seminar competes with a leak caught early or a night truck roll avoided. No infographic that offsets the cost of a failed compressor. No Earth Day statement that reduces overtime for a technician who got a late-night call because a system went down.

If we want to promote real environmental awareness in this industry, we have to build literacy through action:

- Let technicians see the impact of their decisions

- Let operators trust the data they’re using

- Let compliance managers stop chasing paperwork and start driving prevention

⚡ Where Sustainability Meets Smart Efficiency

The Refrigerant Leak Project is built on this premise: Better literacy comes from better tools, not more slogans.

So, let’s stop educating people about awareness and start enabling them to be effective. That’s how we build operational sustainability—on the ground, in real time, with systems that help people do their jobs better. The most sustainable systems are the ones that actually work.

The Role of the Private Sector

Re-centering the Conversation Around People, Not Logos

When we discuss the role of the private sector in environmental progress, the conversation too often drifts toward corporate climate goals, ESG reports, and executive statements. But the real impact doesn’t come from boardrooms. It comes from the people in the field—those who maintain systems, respond to failures, and make hundreds of small daily decisions that determine whether a building runs cleanly, efficiently, or at all.

The private sector doesn’t reduce emissions—its people do.

They do it by:

- Catching refrigerant leaks before they escalate

- Profiling assets in the middle of tight service windows

- Reviewing BMS data to identify faults before they cause downtime

- Working nights and weekends to keep cold chains intact and buildings comfortable

It’s not the policy—it’s the practice.

And the people doing the practice are the ones driving real change.

That’s why our focus is on them.

The frontline workforce—the service technicians, facility operators, and energy managers—isn’t looking for applause. They’re looking for clarity, systems that don’t make their jobs harder, and tools that respect their time, knowledge, and pressure to perform.

💼 Business as a Force for Environmental Change

Only When It Prioritizes Its People

If business is going to be a force for environmental change, it has to start by investing in its people, not just its public image.

Because the biggest carbon savings don’t come from a press release.

They come from:

- A leak occurred three days earlier than usual

- A truck that never rolled because the data told the truth

- A technician who could skip a second visit because the first one was better informed

Yes, building automation systems, leak detection platforms, and fault diagnostics matter—but only when they are implemented in ways that serve the workforce, not just the compliance office.

Resiliency doesn’t begin in software. It begins in trust.

When we give workers tools that help, not hinder, the result is more than just efficiency.

It’s retention. It’s safety. It’s pride.

That’s where environmental progress becomes sustainable—not just in a planetary sense but also in an operational one.

Because when you center the people on the roof, in the mechanical room, or rolling between sites, you don’t just move the needle on emissions.

You move the needle on everything.

So if a business wants to lead, it has to listen first to the workforce that already knows what’s broken and how to fix it, if only we’d give them the tools to act.

That’s not just good for the environment.

That’s good business.

🧱 The Workforce Is the Movement

We don’t need another campaign. We need a foundation.

If we want to cut emissions and keep systems running efficiently, we need to start designing for the people responsible for the work. And that means:

- Simplify compliance so it doesn’t add stress

- Delivering tools that integrate with real workflows, not imaginary ones

- Telling stories that reflect the realities of the job, not the ideals of the boardroom

Because if we only speak to the aspirational crowd—the sustainability officers, the ESG strategists, the policymakers—we’ll never address the technicians, mechanics, and operators already trying to hold this thing together.

After doing this for so long, it is clear that they don’t need inspiration; they need clarity, support, tools for effectively detecting issues in building systems, and the assurance that someone is designing for them.

Thesis: Imagine prioritizing the workforce in every decision you make—where tools don’t replace people, they empower them.

At the heart of our work lies a simple but transformative idea: people come first. Our approach rejects the trend of automating for automation’s sake. Instead, we integrate technology to amplify human capability, not to displace it. Whether it’s through proactive leak detection, simplified compliance workflows, or AI-enhanced diagnostics, we’re building systems that are intuitive, supportive, and designed to relieve pressure, not create it.

By putting the workforce at the center, we unlock smarter maintenance, stronger compliance, and a more resilient, engaged operational culture. The result isn’t just better performance—it’s a workforce that’s seen, supported, and prepared for the future.

🛠️ Less Downtime. More Earth Time.

How We’re Building Differently—and How You Can Join Us

This is why we’ve spent the past year investigating solutions and working closely with partners to prioritize usefulness over hype:

- AKO – leak detection as a service – hardware backed up by people

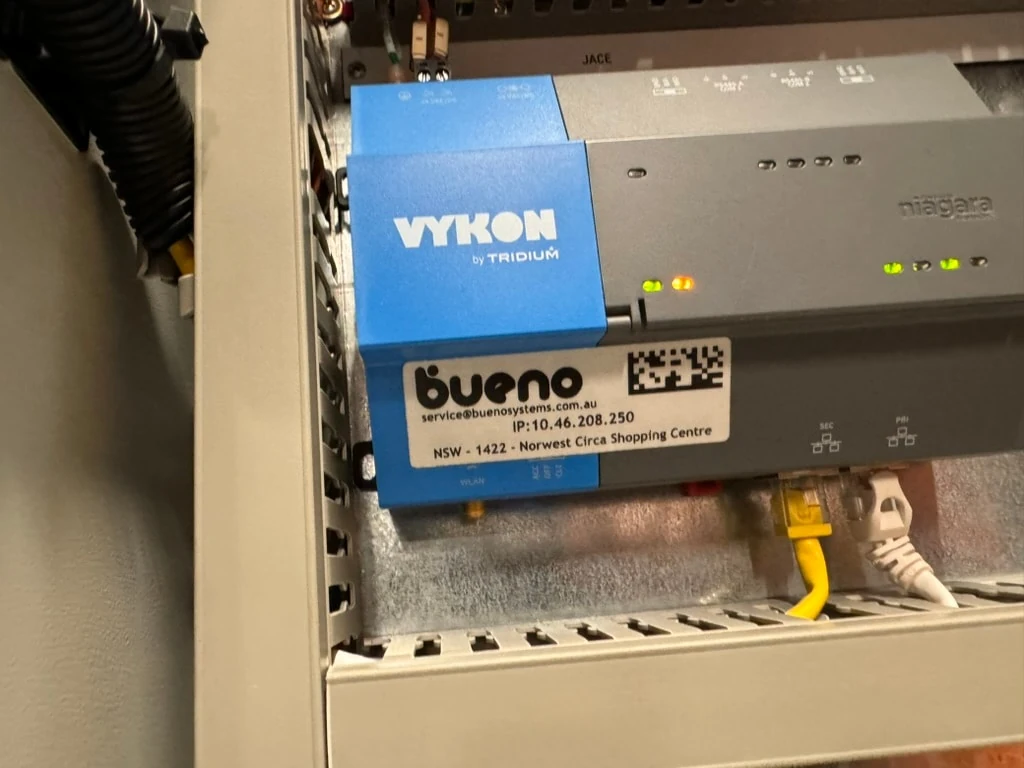

- Bueno’s logic engine isn’t just analytics. It helps operators make real-time decisions with the data they already have.

- Tag Wizard isn’t a compliance wrapper. It’s a tool built for people who scan tags with one hand while holding a clipboard in the other.

As we move forward, we’re inviting people into this mission, not as buyers, but as partners:

- If you’re a technician who wants to test our asset tagging app, you’re welcome – no charge.

- Let’s talk when you’re a grocer bringing insights to your operations and using BMS data to guide your workforce.

- If you need leak detection and are tired of running HVAC/R systems without reliable oversight, we can help. We have a small loaner fleet you can try.

- If you believe this industry should be a better place to work, we agree.

These tools help save money by improving efficiency and simplifying maintenance.

Because this isn’t about becoming “smarter.” It’s about being more effective together.

🛠️ Earth Day Still Means Something

Let’s stop chasing symbols and start delivering systems that work.

Let’s build careers people can be proud of. Let’s tell our stories from rooftops and truck cabs, not press releases. Let’s make the next generation want to join this industry, not because it looks good on a resume, but because it feels like a future. The environmental movement won’t succeed through awareness alone. It will succeed when the people who fix things are the ones driving the change. Environmental issues directly impact human health, with harmful substances like microplastics in the human body raising concerns about public health. And that’s the story we’ll keep telling. From the field. For the field. Because in the end, it’s not the global order that’s going to solve this. It’s the people keeping the air-conditioned and monitoring the temperature to ensure optimal operation and energy savings.

🔧 What We Learned Is in What We Build

We consider our work a community initiative that provides valuable insights into the collective action’s power. By working together, the stakeholders in this industry are also members of this community. Together, we address local issues more effectively and create a stronger sense of community. The initiative also highlighted the importance of communication and collaboration in achieving common goals.

1️⃣ Repurpose Existing Data—Don’t Rebuild the Infrastructure

In Australia, I saw facilities using fault detection and diagnostics to extract real insights from their building automation systems. They weren’t replacing what worked—they were making the most of what was already installed.

Platforms like Bueno didn’t just monitor—they analyzed. They identified patterns, flagged emerging issues, and helped prioritize technician responses—whether the problem was a refrigerant loss, system inefficiency, or a failed setpoint. Fault detection and diagnostics are typically used to diagnose equipment failures and optimize system performance.

We adapted that model for the U.S., tailoring AFDD for HVAC/R and refrigeration teams working across grocery, retail, and commercial portfolios. Effective leak detection starts with understanding what your system is already telling you.

2️⃣ Build Systems That Lighten the Load—Not Add to It

In Spain, I met grocers who didn’t treat refrigerant leaks as surprises. Their stores were equipped with refrigerant leak detection sensors that required no calibration, minimal maintenance, and very little interpretation. These sensors didn’t just detect—they alerted, triggered workflows, and helped protect inventory and equipment.

These ultra-sensitive sensors effectively detect various halogen-based refrigerants, ensuring precision in challenging detection scenarios. But the real success is in how the AKO team profiles the leaks and contacts the affected locations.

Combined with AKO’s field-proven sensor hardware, BARLO gives teams early visibility into issues before parts fail, food spoils, or overtime gets called in. Effective control systems are crucial in managing building operations, optimizing energy efficiency, and integrating multiple operational functions through advanced technology. When your systems reduce the noise and raise the right flag at the right time, everyone gets to work smarter, not harder.

Treat Compliance as Infrastructure, Not Interruption

Regulations like California’s ALD mandates and New York’s Rule 494 have made refrigerant tagging and tracking unavoidable. But the best teams aren’t resisting these changes—they’re using them to build better systems.

The integration of heating systems with other utilities, such as electricity and air conditioning, in building management systems (BMS) enhances operational efficiency and occupant comfort.

The private sector’s involvement in environmental initiatives, such as the Climate Rally, highlights the importance of collaboration between governmental and private entities in advancing sustainability and climate action.

We created Tag Wizard—a flexible, adaptable refrigerant asset tagging solution for field deployment, EPA compliance, and internal alignment.

Stop Guessing, Start Tagging

Whether tagging cylinders, labeling fixed systems, or marking assets under repair, Tag Wizard was built to track and identify equipment. If you need to document service events, there is always Trakref. You can also stay ahead of state and federal enforcement. Compliance shouldn’t be a fire drill—it should be a foundation.

🚚 Earth Day Isn’t Just About Emissions. It’s About What Gets Done

It’s easy to talk about goals, but real progress shows up in the details: Our goal is to flip the script to a more effective environmental performance, which should be matched with:

- One less truck roll

- One more technician will be home on time

- One more system was fixed before it failed

- One more early alert that avoided a costly response

Alarms are crucial in monitoring systems, providing early alerts to hazardous conditions and integrating with building management systems for enhanced safety.

These operational moments prevent emissions, preserve margins, and protect teams. That’s what effective refrigerant management looks like.

🌐 Building Automation and Energy Efficiency

Innovations in Energy Management and Their Impact

Building automation systems (BAS) are revolutionizing how we manage energy efficiency in commercial and industrial buildings. These innovative building technologies, including energy management systems, significantly reduce energy consumption and costs and are intrinsically connected and impacted by operations. This last year has proven that the tech to solve our problems is out there, and our goal is a unified and efficient building automation solution that delivers better outcomes across the board.

Earth Day themes have championed sustainability and energy efficiency in buildings, promoting practices beyond symbolism to deliver measurable outcomes. By embracing innovation and forward-thinking design, owners and operators can improve their environmental impact while cutting energy costs and providing a better work environment. These aren’t just green initiatives—they’re operational upgrades. The result is a win-win: enhanced system performance, long-term savings, and a direct contribution to a more sustainable future.

Looking Ahead: Join the Mission—And Help Shape What’s Next

This past year wasn’t about product launches but learning from the field and aligning with what works. We didn’t chase innovation for its own sake. We listened to what technicians, operators, and compliance leaders needed and built around that.

Building systems present an opportunity to enhance energy efficiency and operational performance by integrating various utilities and sensors through Building Energy Management Systems (BEMS) and Building Automation Systems (BAS). There are not enough workers to handle all the tasks, and buildings that wish to leverage the technology in which they have already invested to connect and power essential systems like lighting, heating, cooling, and safety features can improve operational performance, but cannot deliver on efficiency, flexibility, and resilience.

Now, heading into the next 12 months, our focus is expanding, but our principles remain the same: operational clarity, real accountability, and systems that support people.

Here’s what the year ahead looks like—and how you can engage:

🔄 Apply Grocery Lessons to Other Critical Sectors

The challenges we are solving with grocers—refrigerant tracking, leak detection, and technician support—aren’t unique to grocery.

- Data centers face the same high-stakes cooling issues, often without visibility until a failure occurs.

- Hospitality venues juggle multiple HVAC/R systems across scattered properties, with thin staffing and tight margins.

- Cold storage, pharma, and retail chains all share the same regulatory pressures and operational blind spots.

Monitoring temperatures is crucial across various sectors, from ensuring optimal conditions in data centers to maintaining comfort in hospitality venues and preserving products in cold storage and pharma.

Automation using AI, insights gained, and special recipes for projecting possibilities before they become issues are applicable at every location.

If you’ve built your expertise in one sector, now’s the time to repurpose those insights across industries. We’re working with partners who see the bigger opportunity: refrigerant management is a cross-sector challenge that requires sector-specific answers.

We’re here to help you translate experience into outcomes, no matter the vertical.

🏷️ Participate in Our Tag Wizard Rollout

As we launch our Tag Wizard asset tagging platform, we invite industry leaders, contractors, and compliance teams to join our early access program.

- You’ll get to test the app in real-world conditions.

- You’ll help shape how tagging, labeling, and reporting are integrated into daily workflows.

- The platform will also contribute to significant energy savings in building operations by optimizing performance and reducing unnecessary energy consumption.

- The integration with the building’s systems will enhance fault detection and diagnostics (FDD), utilizing the building’s data network for better automation and management.

- Your feedback will directly influence how the next version supports field techs and back-office teams alike.

We’re keeping the barrier to entry low—use your own labels, scan with your phone, and track refrigerants anywhere. No long onboarding. No contracts. Just clarity. If you want to stay ahead of refrigerant regulations and help build the future of asset tracking, now’s the time to raise your hand.

🤝 Help Us Make the Industry a Better Place to Work

Behind every sensor, tag, and data point is a person, and our mission has always been to support those people.

We believe that refrigerant compliance isn’t just an environmental responsibility—it’s a workforce responsibility.

- When systems work well, technicians go home on time.

- When alerts are clear, stress drops and job satisfaction rises.

- When compliance tools are reliable, the next generation sees HVAC/R not as a fallback, but as a career with purpose.

- When tools work in enhancing operational efficiency, they reduce stress for technicians and improve overall system performance.

🔑 Key takeaway

Efficient systems, such as Building Energy Management Systems (BEMS), can significantly reduce energy costs by optimizing energy use through monitoring and controlling HVAC and lighting systems.

In the year ahead, we’re doubling down on our commitment to:

- Reduce burnout.

- Retain experienced talent.

- Attract new people to this industry with new tools, better workflows, and a culture of respect.

If that resonates with you—if you want to be part of shaping the next chapter in HVAC/R, refrigeration, or data center operations—we’re here. And we’re listening.

🎉 Earth Day Celebrations and Events

Engaging Communities and Celebrating Progress

Earth Day, celebrated annually on April 22, is more than just a day—it’s a reminder that more than just the balance sheet is at stake. Earth Week activities extend throughout the month and are organized by a broad, decentralized Network to promote environmental awareness and sustainability. Community engagement is at the heart of Earth Day celebrations, with local events and activities encouraging individuals to take action on environmental issues.

College campuses and universities significantly promote environmental literacy and sustainability through Earth Day events and initiatives. These celebrations focus on critical issues such as climate change, plastic pollution, and conservation, highlighting the importance of individual actions and collective efforts in addressing these challenges.

Today, Earth Day celebrations spotlight sustainability wins and future-forward innovations—but let’s also recognize the people who make it happen every day.

Behind every energy-efficient building, emissions reduction, and operational upgrade are the owners, operators, and support teams who show up—not for applause but because it’s their job, craft, and commitment to do things right.

These professionals aren’t just acting on Earth Day—they’re living out “think globally, act locally” daily. They fine-tune systems, respond to failures, and push for better performance because it’s what they’re trained to do. It’s their skill, livelihood, and contribution to something bigger.

So today, let’s celebrate the workforce behind the mission—the people who deliver sustainability not through slogans, but through action…

🌍 Earth Day Is a Starting Point

We’ve spent the past year watching, building, and refining. Now, we’re opening the door wider.

This isn’t a product pitch. It’s a mission. A mission is to reduce emissions, improve outcomes, and support the people doing the work. We are also committed to utilizing advanced tools like the H-10 PRO Refrigerant Leak Detector, which is specifically designed to detect all halogen-based, non-flammable refrigerants, including CFC, HFC, and HCFC types.

Harnessing the power of light through sustainable energy solutions like solar energy can illuminate homes and communities while contributing to environmental conservation.

So if you’re ready to:

- Trial the Tag Wizard platform

- Adapt Bueno’s analytics to your facilities

- Explore how AKO can support your leak detection goals

- Or start a conversation about how to make your operations easier to manage

We’d love to hear from you.

Because when systems work, leaks are caught early, and teams feel supported, the environment improves, efficiency returns, and people stay. And that’s what Earth Day should be about: Progress that lasts.