Incorporating ASHRAE 36 into FDD Solutions: Limitations and Potential

In one of my many conversations

ASHRAE 36, titled High-Performance Sequences of Operation for HVAC Systems, is a new guideline that provides standardized control sequences to optimize HVAC system performance and building automation systems. It aims to maximize energy efficiency, improve indoor air quality, and provide control stability. ASHRAE is traditionally a leader in establishing industry standards, and ASHRAE 36 offers useful sequences of operation that help ensure better control of HVAC systems.

However, regarding cutting-edge technology like Fault Detection and Diagnostics (FDD), ASHRAE 36 falls short in fully capturing the power and potential of modern, data-driven solutions. While ASHRAE 36 is an important document that provides a solid foundation for HVAC operations, it is limited in its scope and approach to leveraging real-time data analytics, where FDD truly excels.

Table of Contents

ToggleUnderstanding ASHRAE 36 and Its Significance in HVAC Systems

ASHRAE Guideline 36 is a crucial document that provides uniform operation sequences for HVAC systems, focusing on energy efficiency, performance, control stability, and real-time fault detection.

Developed by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), this guideline addresses common issues in designing, installing, and testing building automation systems (BAS). By providing standardized advanced control sequences, Guideline 36 helps reduce engineering time, programming and commissioning time, and energy consumption, ultimately leading to improved indoor air quality (IAQ) and enhanced communication among specifiers, contractors, and operators.

The significance of ASHRAE 36 lies in its framework for designing high-performance sequences of operations, which can lead to improved control stability and real-time fault detection.

This guideline is essential for maintaining and publishing high-performance control sequences, ensuring that HVAC systems meet or exceed published ASHRAE standards. By adopting Guideline 36, facility owners and control manufacturers can participate in the programming and testing of these sequences, leading to improved energy efficiency and performance.

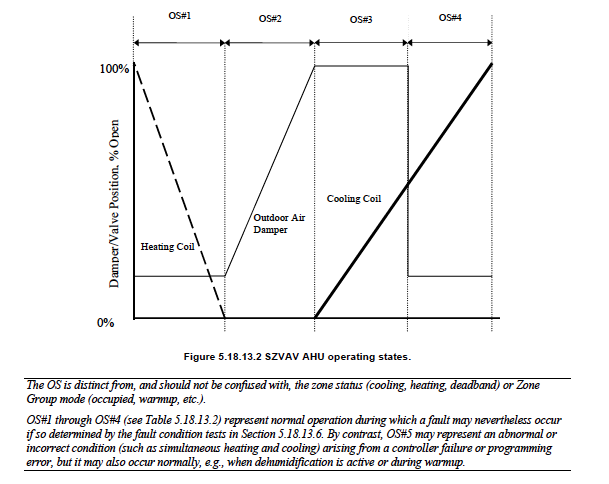

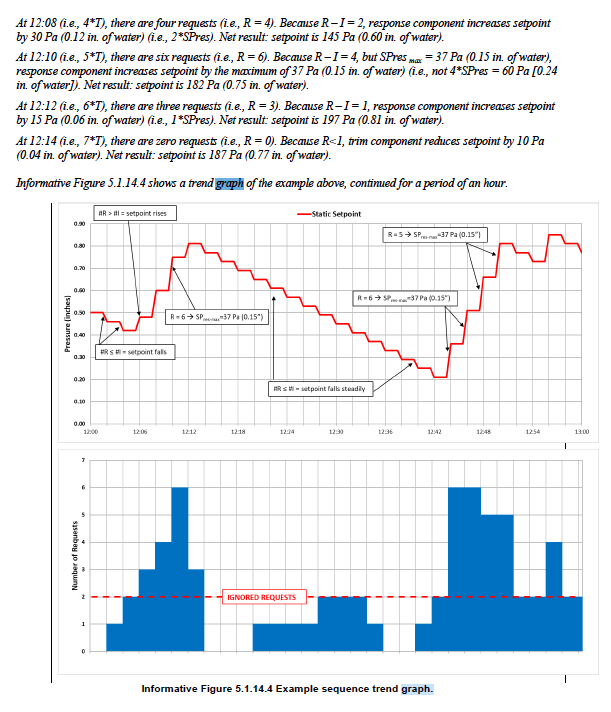

ASHRAE 36: An Overview of Control Stability

ASHRAE 36 lays out standardized operation sequences for HVAC systems, guiding HVAC designers, contractors, and building operators.

The ASHRAE Research Project, including initiatives like RP-1711 and RP-1865, plays a crucial role in developing these guidelines by creating advanced control sequences that optimize energy efficiency and performance.

The guidelines focus on improving energy efficiency and operational stability through tested sequences of control that reduce engineering and programming time, minimize commissioning challenges, and improve overall system reliability.

ASHRAE 36 helps to ensure that HVAC systems are less dependent on perfect installation or control system design, as it simplifies the sequences of operation that need to be implemented. This guideline has been instrumental in advancing best practices for control and efficiency in the HVAC industry(ASHRAE 36 -D-86870 (1)).

Limitations of Current FDD Solutions

While advanced, Current Fault Detection and Diagnostics (FDD) solutions face several limitations that can hinder their effectiveness in improving control stability and energy efficiency in HVAC systems. One significant challenge is the absence of standardized operation sequences, which can lead to inconsistent and inefficient control strategies across different systems.

This lack of uniformity often results in varied performance outcomes, making achieving optimal energy efficiency and control stability difficult.

Moreover, many FDD solutions rely heavily on manual data analysis and interpretation. This process can be time-consuming and prone to human error, reducing the overall effectiveness of the diagnostics. Many existing FDD solutions focus primarily on detecting faults rather than preventing them.

This reactive approach can lead to increased energy consumption and decreased control stability, as issues are addressed only after they have already impacted system performance.

To overcome these limitations, a new approach is needed—one that incorporates standardized sequences of operation and leverages advanced technologies and data analytics to provide real-time fault detection and diagnostics.

By integrating these elements, FDD solutions can move from reactive to proactive, enhancing energy efficiency and control stability in HVAC systems.

FDD vs. ASHRAE 36: Gaps in Guidance

While ASHRAE 36 provides uniform sequences that help improve HVAC performance, it is more of a tactical guide that stops short of addressing the potential of advanced technologies like FDD.

FDD technology, as implemented through platforms such as Bueno, goes beyond the standardized sequences provided by ASHRAE 36. It harnesses real-time data analytics, machine learning, and automated diagnostics to detect faults before they cause performance degradation or failures.

ASHRAE 36 may standardize control sequences for optimized operations, but it doesn’t fully account for the dynamic nature of equipment performance or the ability to predict and prevent faults through data-driven insights.

For instance, while ASHRAE 36 emphasizes reducing energy consumption and improving operational efficiency through standardized sequences, it doesn’t integrate an FDD system’s advanced fault detection capabilities.

FDD solutions identify and rectify inefficiencies, system anomalies, and emerging faults in real time, which ASHRAE 36 sequences alone cannot accomplish.

Bueno’s FDD platform, for example, surpasses the guidelines set by ASHRAE 36 by using machine learning and big data analytics to optimize performance and predict issues before they escalate (ASHRAE 36 -D-86870 (1)).

Improving Control Stability with ASHRAE 36

ASHRAE Guideline 36 offers a standardized approach to designing and implementing high-performance operation sequences for HVAC systems. By adhering to this guideline, building owners and operators can significantly improve control stability, reduce energy consumption, and enhance indoor air quality. The guideline provides a comprehensive framework for designing operation sequences optimized for energy efficiency and control stability, ensuring that HVAC systems operate at peak performance.

One of the key features of ASHRAE Guideline 36 is its inclusion of Automated Fault Detection and Diagnostics (AFDD). This technology enables quick identification and diagnosis of system faults, allowing for timely interventions that prevent minor issues from escalating into major problems. By implementing ASHRAE Guideline 36, building owners and operators can ensure that their HVAC systems are efficient and reliable, providing a comfortable and healthy indoor environment while minimizing energy waste.

Technical Considerations for Implementation

Implementing ASHRAE Guideline 36 requires careful consideration of several technical factors to ensure successful integration and operation. One primary consideration is the selection of control systems and devices compatible with the guideline’s requirements. Building owners and operators must ensure that their HVAC systems are designed and installed to support the implementation of high-performance operation sequences.

Additionally, the guideline mandates using Automated Fault Detection and Diagnostics (AFDD), which must be properly configured and integrated with the control system. Although a professional can apply some settings with experience, the Bueno team has learned that collecting data for some time and creating a baseline will enable you to calibrate your settings as your data journey progresses. Ashrae is often referred to as AFDD, and as such, this integration is crucial for the AFDD to function effectively, providing real-time fault detection and diagnostics that enhance system performance.

To ensure a smooth and successful implementation, ASHRAE advises building owners and operators to work with experienced designers and contractors familiar with Guideline 36 and its requirements. Companies like Bueno, with a decade of experience, These professionals can provide the expertise needed to navigate the technical complexities and ensure that the HVAC systems are optimized for performance and efficiency.

Why ASHRAE 36 Is Still Relevant for High-Performance Sequences

Despite its limitations, ASHRAE 36 remains a valuable guide for establishing a foundational operational standard for HVAC systems. ASHRAE 36 plays a crucial role in optimizing air conditioning systems by outlining best practices for their operation. Its standardized sequences reduce the engineering and commissioning time required to implement efficient control systems, ensuring that HVAC systems operate according to best practices.

The relevance of ASHRAE 36 is seen in how it streamlines the implementation of high-performance control sequences, making it easier for contractors and engineers to ensure HVAC systems perform to a minimum standard. Moreover, ASHRAE 36 includes fault detection elements, such as diagnostic software, that helps building operators be aware of issues before they impact performance. This is a useful step towards modern FDD solutions’ more comprehensive and robust fault detection capabilities.

Platforms like Bueno fully comply with ASHRAE 36, incorporating its high-performance operation sequences. However, they take the next step by offering enhanced fault detection capabilities that surpass ASHRAE’s basic control sequences. Bueno’s system meets all ASHRAE 36 qualifications. Still, it goes beyond delivering predictive maintenance, real-time insights, and energy optimization that allow businesses to achieve far greater efficiency and sustainability outcomes than what ASHRAE 36 alone can provide(ASHRAE 36 -D-86870 (1)).

FDD and Its Advantages Over Traditional Guidelines: Real-Time Fault Detection

FDD solutions like Bueno’s offer far more than just implementing high-performance sequences. While ASHRAE 36 is focused on control stability and achieving set operational standards, the new guideline enhances the design, installation, and commissioning processes of HVAC systems. FDD systems are designed to continuously monitor, diagnose, and provide real-time recommendations for improving system performance. With Bueno’s FDD platform, businesses can ensure that their HVAC systems follow the best sequences laid out by ASHRAE and perform optimally at all times. This difference is crucial, as it enables businesses to move beyond the static compliance of ASHRAE 36 and into dynamic, real-time system optimization.

Moreover, FDD solutions enhance sustainability by proactively preventing system inefficiencies, helping businesses reduce energy consumption and meet their sustainability goals more effectively. ASHRAE 36 focuses on achieving operational efficiency, but it lacks the tools to actively monitor system health, predict equipment failures, and prevent downtime like FDD solutions do.

Case Studies and Real-world Applications

Several case studies and real-world applications have demonstrated the effectiveness of ASHRAE Guideline 36 in improving control stability and energy efficiency in HVAC systems. For instance, a recent study conducted in a commercial office building revealed a 25% reduction in energy consumption and a 30% improvement in control stability after implementing the guideline. This significant improvement underscores the potential of ASHRAE Guideline 36 to enhance HVAC system performance.

Another compelling case study involved a hospital that adopted ASHRAE Guideline 36. The results were impressive, with a 15% reduction in energy consumption and a 20% improvement in indoor air quality. These outcomes highlight the guideline’s practical benefits, demonstrating its ability to create a comfortable and healthy indoor environment while minimizing energy waste.

These case studies provide concrete evidence of ASHRAE Guideline 36’s potential to improve HVAC systems’ performance. By following the guidelines, building owners and operators can achieve substantial energy savings and enhance their HVAC systems’ overall stability and efficiency.

Future Directions for FDD Solutions

Fault Detection and Diagnostics (FDD) solutions are critical in ensuring the optimal performance of HVAC systems. As the industry continues to evolve, FDD solutions must adapt to meet the changing needs of building owners and operators. Future directions for FDD solutions include:

Integration with ASHRAE Guideline 36

FDD solutions should be designed to work seamlessly with Guideline 36, providing real-time fault detection and diagnostics to ensure that HVAC systems operate at optimal levels.

Meeting EPA 608 Leak Requirements

FDD solutions should be capable of detecting refrigerant leaks and providing alerts to facility managers, ensuring compliance with EPA 608 regulations.

Advanced Analytics

FDD solutions should incorporate advanced analytics to provide insights into HVAC system performance, energy consumption, and maintenance needs.

Cloud-Based Platforms

FDD solutions should be cloud-based, allowing for remote monitoring, access to real-time data, and collaboration among stakeholders.

Artificial Intelligence and Machine Learning

FDD solutions should leverage AI and ML to improve fault detection and diagnostics, predict maintenance needs, and optimize HVAC system performance.

By embracing these future directions, FDD solutions can play a critical role in ensuring the optimal performance of HVAC systems, reducing energy consumption, and meeting regulatory requirements.

Why FDD Is the Future of Energy Efficiency, a Powerful Maintenance Tool, and Key to Meeting EPA Refrigerant Leak Detection Requirements

While ASHRAE 36 provides a solid foundation for designing and operating HVAC systems, it falls short for modern businesses seeking full system optimization through advanced technology. ASHRAE 36 offers standardized operational sequences that improve control and energy efficiency, but companies today need more than just operational guidelines. Fault Detection and Diagnostics (FDD) platforms, like Bueno’s system, elevate HVAC management to new levels by using real-time data analytics, predictive maintenance, and advanced fault detection capabilities that far surpass the traditional scope of ASHRAE 36.

FDD is reshaping the future of HVAC system optimization, allowing businesses to increase energy efficiency, improve maintenance outcomes, and comply with regulatory standards, including the EPA’s refrigerant leak detection requirements under Section 608. While ASHRAE 36 provides a good starting point, FDD technology empowers businesses to move from a static, reactive model to a dynamic, predictive framework that leads to continuous system improvement.

One of the standout features of FDD, particularly with Bueno’s platform, is its ability to enhance energy efficiency beyond what ASHRAE 36 guidelines alone can achieve. ASHRAE 36 sets out control sequences that help manage energy use. Still, FDD takes this a step further by continuously monitoring system performance in real-time and identifying inefficiencies as they emerge. Bueno’s FDD platform uses machine learning and advanced algorithms to detect even the smallest system deviations, allowing HVAC systems to operate at peak efficiency. This real-time, data-driven approach to energy management results in more significant savings than can be realized by following fixed operational guidelines.

Regarding maintenance, FDD revolutionizes the traditional reactive maintenance model, where issues are addressed after they occur, or preventive maintenance, which relies on periodic inspections. ASHRAE 36 can guide system operation, but it doesn’t provide the predictive insights that an FDD system does. Bueno’s FDD platform enables predictive maintenance by identifying potential issues before they become failures, allowing businesses to avoid costly emergency repairs and unplanned downtime. Predictive maintenance reduces system downtime and extends the overall lifespan of HVAC equipment, minimizing capital expenditures over time. The EPA has prioritized one form of predictive maintenance called leak inspections. The earlier we find refrigerant leaks, the less gas will leak – and for that reason, FDD offers an entry point not included in Guideline 36

FDD’s contribution to regulatory compliance is especially significant in meeting EPA refrigerant leak detection requirements under Section 608. The EPA mandates that businesses track refrigerant use closely and detect leaks promptly to reduce environmental impact. ASHRAE 36 focuses on general operational efficiency, but it doesn’t provide the sophisticated leak detection capabilities that FDD systems like Bueno’s can offer. Bueno’s platform, mainly through its Barlo (Bueno Advanced Refrigerant Leak Optimization) system, is designed to meet these regulatory requirements more efficiently and precisely.

Barlo is an indirect leak detection system, meaning it doesn’t rely on traditional physical leak detectors that require extensive tubing or placement in multiple locations.

Instead, Barlo leverages data from existing systems, such as liquid-level controllers, using Bueno’s cloud-based analytics to detect leaks digitally. One key advantage of this approach is that no physical calibration is required, a significant cost-saving measure compared to traditional leak detection systems that need regular manual calibration. The digital nature of Barlo’s FDD capabilities ensures that leaks can be predicted well in advance, saving businesses from costly emergency labor related to system breakdowns and failures.

Moreover, indirect leak detection with Barlo eliminates the need for physical leak detectors in multiple locations, which are often expensive, cumbersome to install, and challenging to maintain. The system’s ability to detect leaks through data analytics reduces the number of physical leak inspections required during the year, cutting labor costs and minimizing disruptions to operations. Businesses using Bueno’s Barlo system have drastically reduced the number of mandated leak inspections from several per year to zero while remaining compliant with EPA regulations.

By predicting leaks before they occur, Barlo enables businesses to take proactive measures to prevent refrigerant loss. Thus, they avoid costly and poorly timed emergency repairs and reduce the need for reactive, break-fix solutions. This protects the environment by minimizing refrigerant emissions and significantly lowers operational costs associated with emergency labor, downtime, and refrigerant replacement.

FDD technology represents the future of HVAC management, and BaRLO represents the first step on that journey. While ASHRAE 36 provides a valuable framework for operational efficiency, it lacks the advanced capabilities to optimize system performance and fully ensure regulatory compliance. Bueno’s FDD platform enhances energy efficiency, improves maintenance outcomes, and provides a comprehensive solution for meeting EPA refrigerant leak detection requirements. For businesses looking to reduce costs, improve system reliability, and meet sustainability goals, FDD is a critical tool that goes beyond the foundational standards of ASHRAE 36 to deliver continuous improvement and long-term success.