Essential Leak Detector HVAC Tools: Find Every Refrigerant Leak Fast

Finding refrigerant leaks in HVAC systems is crucial for maintaining efficiency and preventing environmental harm.

A leak detector HVAC can make this task easy and effective.

This article will guide you through the types of detectors available, their key features, and how to use them properly.

Additionally, ensuring compliance in leak detection is essential for adhering to regulations and standards.

Table of Contents

ToggleThe Art (and Science) of Finding Refrigerant Leaks

I’ve been finding refrigerant leaks in refrigeration and AC systems for 32 years. Even as I take on less front-line work, I still try to get out there because, for as long as I’ve been doing this work, leak detection has felt more like an art than a science.

For those who have never done it, leak checking a refrigeration system is like searching for a needle in a haystack—except the haystack has miles of tubing, some overhead, some underground, some in machine rooms, and some tucked away in cabinets. Joints, valves, and fittings can leak for days, sometimes at a rate so small that you wouldn’t notice until it’s too late.

When your handheld leak detector picks up a reading, that’s when the real work begins.

Big leaks can trigger alarms 10 feet away from the source, leaving you staring at 50 potential fittings. You go one by one, methodically testing each connection, and when you finally find it—that moment is unbeatable.

Even now, when techs call me from the field, walking through piping layouts over the phone, I still get a thrill when I hear them say, “I got it.”

Why Leak Detection Became My Mission?

Last year, when my old company took a new direction, I never hesitated in choosing what mattered to me: finding refrigerant leaks.

It’s not the most glamorous job in HVAC/R. Many techs prefer controls, design, or system optimization. Leak detection is fundamental—it’s the backbone of system reliability—but it’s also one of the most frustrating tasks in the industry.

Some techs are incredible at it. Others avoid it at all costs.

So, when I had the chance to forge a new path, I made finding the best leak detection solutions my top priority. Effective refrigerant leak detection helps avoid compliance issues, ensuring that systems operate within regulatory standards.

I hit the road, went to trade shows, rode in trucks with service techs, walked store aisles, and visited the toughest leak-prone areas. That’s when I realized: there’s a better way.

I was fortunate to connect with a dedicated group from Spain who shared my commitment.

They understood the problem inside and out. That’s the day when I knew I had found my people.

We are on a mission to redefine refrigerant leak detection.

Fixed Leak Detection: The Future of Finding Refrigerant Leaks

There are two types of leak detection:

- Handheld Leak Detectors

The tools every tech carries in their bag. We’ll tackle this challenge another day. - Fixed Leak Detection

The game-changer in preventing refrigerant loss, compliance issues, and unnecessary costs. Fixed leak detection systems offer continuous monitoring, ensuring that leaks are detected and addressed promptly.

Today, I want to focus on mobile leak detection—specifically hand held devices that are commonly used in the field, but next week I will revisit the companion technology of fixed leak detection and NDIR (Non-Dispersive Infrared) sensors and the latest evolution: indirect leak detection.

These technologies are transforming how we detect, track, and prevent refrigerant leaks, making leak detection less of an art and more of a science.

Stay tuned. We’re just getting started.

📌 Key Takeaways

HVAC leak detectors are essential tools for identifying refrigerant leaks, crucial for maintaining system efficiency and environmental protection.

- Various types of leak detectors, including electronic, ultrasonic, dye-based, and halide detectors, offer distinct features and capabilities suited for specific leak detection needs.

- Proper maintenance and usage of leak detectors improve their effectiveness, ensuring accurate readings and prolonging their operational life.

- Compliance with industry standards and regulations is a key reason for using HVAC leak detectors, ensuring safety and adherence to legal requirements.

Understanding HVAC Leak Detectors

HVAC leak detectors are indispensable tools for identifying refrigerant leaks, which, if undetected, can severely impair system efficiency and harm the environment. In commercial settings, robust leak detection is vital for maintaining comfort and operational safety.

These detectors sense refrigerant gases in the atmosphere and alert users to potential leaks, safeguarding the system and the environment. Robust leak detection also helps avoid compliance issues, ensuring that systems meet regulatory standards.

The functionality of HVAC leak detectors is rooted in their ability to spot specific gases. Automated leak detection systems, which offer continuous monitoring, have revolutionized the industry by enhancing the reliability and effectiveness of leak detection efforts.

This continuous vigilance ensures that even the smallest leaks are identified and addressed promptly, thus maintaining optimal system performance and promoting environmental health.

Understanding how these tools operate and their significance in HVAC maintenance allows for deeper exploration into the varieties of refrigerant leak detectors and their features.

Effective leak detection leads to better performance and a healthier environment, making these tools an essential part of any HVAC professional’s toolkit.

What are the types of Leak Detectors for HVAC Systems?

There is a diverse range of refrigerant leak detectors available for HVAC systems, each designed with specific detection methods to cater to different needs.

Electronic detectors, for instance, include infrared, heated diode, and corona discharge detectors, known for their accuracy and sensitivity to various refrigerants.

These detectors are particularly useful in environments where precise detection of small leaks is critical.

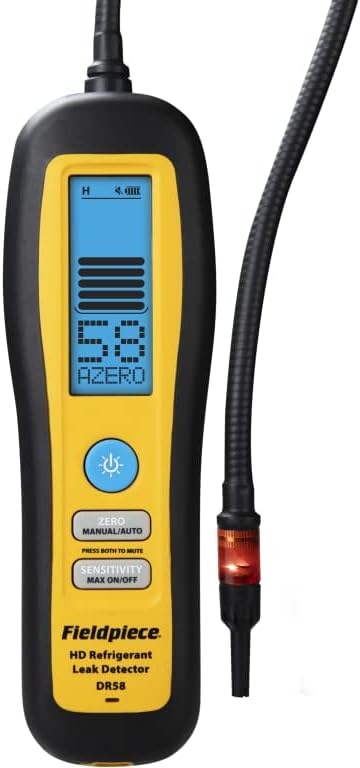

Here are two examples of Handheld Portable leak detectors:

Ultrasonic detectors work by amplifying sound waves generated by gas leaks, enabling detection at a distance and in pressurized systems. This makes them ideal for identifying leaks in hard-to-reach areas where other detectors might struggle to spot them.

Dye-based detectors, on the other hand, involve adding oil additives to the system, with leaks identified by detecting UV light. Although effective, these detectors can sometimes pose safety risks if not designed or handled properly. Halide detectors, which indicate leaks through changes in flame color, also fall under this category but come with their own set of risks.

Each type of refrigerant leak detector has its strengths and weaknesses, and understanding these can help you choose the right tool for your specific HVAC maintenance needs.

From electronic to dye-based methods, each refrigerant leak detector and type plays a crucial role in maintaining the integrity of HVAC systems.

Top HVAC Leak Detectors on the Market

When selecting a leak detector, certain key features can significantly enhance its effectiveness.

Sensitivity is paramount; a highly sensitive leak detector can identify even the smallest leaks, preventing minor issues from escalating.

The Fieldpiece DR58 Refrigerant Leak Detector, for example, can spot leaks as minute as 0.03 oz/year, while the Elitech ILD-200 detects leaks as low as 0.014 ounces per year.

The speed and time at which a refrigerant leak detector identifies a leak also affects overall efficiency. Technicians often work under time constraints, and a fast-acting detector can save valuable time.

Ease of use is also important.

Devices like the Klein Tools ET160 spot refrigerants at levels as low as 100 ppm, making them accessible even for those with minimal training.

We are on a mission to redefine refrigerant leak detection.

Advanced display technologies can enhance user experience.

The Robinair LD7, for example, features a color graphic display system that visually represents leak sizes, giving quicker and more accurate assessments.

These features collectively make refrigerant leak detectors not only effective but also efficient and easy to use, ensuring technicians can perform their tasks swiftly and accurately.

The FLIR Camera: The Pinnacle of Leak Detection

The fanciest, most advanced leak detection tool out there is without a doubt the FLIR (Forward-Looking Infrared) camera found here. This thing is amazing. Unlike handheld electronic sniffers or fixed sensors that rely on detecting refrigerant concentration in the air, the FLIR camera sees refrigerant leaks in real-time—literally making the invisible, visible. FLIR cameras are particularly effective in pressurized systems, where they can quickly identify leaks that might otherwise go unnoticed.

How It Works?

FLIR cameras use optical gas imaging (OGI) technology to detect refrigerants by picking up on the infrared absorption characteristics of gas molecules. Since refrigerants absorb infrared light differently than the surrounding air, the camera creates a thermal contrast, allowing you to see the leak as a cloud or plume escaping from valves, fittings, or tubing.

Why It’s a Game-Changer?

- No More Guesswork

You can scan an entire system from a distance instead of waving a handheld detector around every single fitting. - Instant Leak Visualization

You don’t have to rely on indirect readings or air concentration levels. You see the refrigerant escaping in real-time. - Faster Inspections

In a large supermarket, warehouse, or industrial setting, a single FLIR scan can detect leaks that would take hours with traditional methods. - Safe & Non-Intrusive

No need to get up on ladders, climb into racks, or disassemble equipment. FLIR lets you find leaks from a safe distance. - Compliance & Documentation

With video and image capture capabilities, it provides proof of leak sources for compliance reporting and internal documentation.

Where It Shines?

FLIR cameras excel in large-scale commercial refrigeration, industrial facilities, and hard-to-access leak points. They’re especially valuable for systems with:

- Miles of piping (like distribution centers)

- Overhead or underground refrigerant lines

- Multi-rack systems with hundreds of connections

- Pressurized systems where leaks are intermittent

The Catch

FLIR technology is not cheap—these cameras can cost upwards of $40,000 depending on the model.

But for large facilities, contractors, and leak detection specialists, the investment pays off in faster diagnostics, reduced refrigerant losses, and compliance with EPA and F-Gas regulations.

The Future of Refrigerant Leak Detection

While FLIR is the top-tier option, it’s not a replacement for fixed leak detection or handheld tools—instead, it’s an elite tool for pinpointing leaks that other methods might miss. As regulations tighten and refrigerant costs rise, technologies like FLIR help companies stay ahead of compliance and operational efficiency.

Would I recommend every service tech to carry one? Not necessarily. But for companies managing hundreds or thousands of refrigeration assets, FLIR cameras can save time, money, and refrigerant in a way no other tool can.

If you haven’t seen one in action, trust me—it’s worth a demo

How to Use a Refrigerant Leak Detector Properly?

Correct use of a refrigerant leak detector is essential for obtaining accurate readings and effective leak detection.

Start by allowing your refrigerant leak detector to self-zero outside before entering a confined space. This step ensures that the detector is not influenced by residual refrigerant in the air, providing a clean baseline for accurate detection.

Continuous monitoring plays a crucial role in ensuring accurate leak detection. After shutting off the HVAC system, wait for about ten minutes to let the refrigerant settle before beginning your leak search. This waiting period helps in getting a more precise reading.

Check the flow indicator in the probe before use to ensure the detector is functioning correctly. Knowing how your specific refrigerant leak detector reacts to different refrigerant concentrations can also enhance accuracy.

Using a calibrated leak reference is generally more accurate than using refrigerant from a tank. Effective detectors often feature visual or audible alarms that quickly alert users to the presence of a leak. While searching, continuously move the probe to avoid false readings, as electronic detectors may auto-adjust to high concentrations if left in one spot for too long.

For infrared detectors, positioning the sensor outside the refrigerant stream prevents rapid degradation and allows for longer operational life. Finally, after detecting potential leaks indoors, return outside to let the meter self-zero again if it indicates refrigerant presence.

Additionally, the soap and water method remains a practical technique for revealing leaks, as escaping gas will form bubbles.

📌 In summary

Proper techniques ensure your refrigerant leak detector performs at its best, offering reliable and accurate results every time.

What are the common challenges in detecting HVAC Leaks?

Detecting HVAC leaks comes with difficult challenges. One primary issue is accessing certain parts of the HVAC system due to their placement or design.

These hard-to-reach areas often become havens for undetected leaks, complicating maintenance efforts.

Detecting HVAC leaks is one of the most difficult tasks in refrigeration and air conditioning maintenance. Leaks are unpredictable, often occurring under specific conditions that make them difficult to detect, requiring timing, experience, and the right tools.

Additionally, compliance issues add to the challenges of leak detection. Below are some of the most common challenges:

1. Leaks Don’t Always Happen When You’re Looking for Them

One of the biggest frustrations in refrigerant leak detection is that some leaks are not constant—they may only appear under certain operating conditions:

- Nighttime Leaks

Refrigeration systems operate differently at night when doors aren’t opening and closing, case loads are lighter, and pressures fluctuate. Some leaks only show up when the store is empty and conditions are stable. - Defrost Cycle Leaks

Many leaks occur during defrost cycles, when coils heat up, causing thermal expansion in tubing and fittings. - Door Closure & Air Pressure Changes

Closing walk-in doors or case doors creates pressure shifts that can temporarily reveal or conceal a leak. - Environmental Exposure (e.g., Bread Proofing)

In bakeries and food production areas, processes like bread proofing release moisture and heat, changing the refrigerant’s behavior and making detection more complex.

📌 Because leaks don’t always happen when it’s convenient

they often require inspections at off-hours or during specific operating conditions. Having a history of pressure trends, temperature shifts, and past leak locations improves detection accuracy.

2. Shutting Down Systems & Coordinating Detection Efforts

Finding a leak often means shutting down a system, which is rarely an easy task in a 24/7 environment like grocery stores, food production, or data centers.

When a system is warmed up, leaks become more apparent because pressure rises, expanding the refrigerant lines and making leaks easier to detect.

However, scanning an entire location requires a coordinated effort:

- Enough personnel to systematically check aisles, racks, and walk-ins

- Moving through a store or facility methodically to avoid missing leaks

- Carefully balancing downtime against the need for accurate detection

In contrast, leaks in cold environments or areas with high-velocity airflow (such as mechanical rooms with large exhaust fans) are nearly impossible to pinpoint.

Refrigerant quickly disperses, making standard handheld leak detectors unreliable in these conditions.

3. Digital Data & Historical Trends Improve Detection

📌 With experience, one of the biggest lessons learned

is that the more digital data and history you have, the better armed you are to find refrigerant leaks.

Refrigerant loss doesn’t always follow a predictable pattern, so relying on past detection data, pressure trends, and historical maintenance logs can guide technicians on:

- When to check for leaks (time of day, system state, temperature conditions)

- Where leaks have historically occurred and what conditions triggered them

- How the system responds to different operating parameters

Leak detection doesn’t always accommodate our circadian clock or lifestyle—sometimes, it has to happen at night, during off-peak hours, or in less-than-ideal conditions. Technology-driven leak detection solutions, remote monitoring, and fixed sensors help reduce the need for middle-of-the-night inspections and provide better predictive maintenance insights.

By understanding these challenges, we can develop better strategies, use advanced leak detection methods, and ensure HVAC/R systems operate efficiently with minimal refrigerant loss.

Environmental factors significantly affect leak detection.

Humidity and temperature variations can influence refrigerant behavior, complicating accurate leak detection. For instance, high humidity levels can cause refrigerants to dissipate more quickly, reducing the chances of detecting a leak using standard methods.

Physical damage or wear over time can further complicate leak detection. Components that have suffered from prolonged use or accidental damage may mask the signs of a leak, making it harder for technicians to pinpoint the exact location.

Knowing these common challenges helps in preparing strategies to overcome them, ensuring thorough and accurate leak detection.

The forgotten requirement of maintaining your HVAC leak detector

Proper maintenance of your refrigerant leak detector is crucial for its longevity and accuracy. Regularly checking it against a calibrated reference leak ensures it remains functional and reliable.

This practice helps in maintaining the sensitivity and accuracy of the detector, which are essential for effective leak detection.

Keeping the leak detector dry and clean is another important aspect of maintenance. Moisture and dirt can significantly hinder the performance of leak detectors, leading to false readings or complete failure of the device.

Storing the refrigerant leak detector carefully to avoid damage to sensitive components, such as pumps and sensors, further extends its operational life.

Regular inspection and maintenance of hoses are important.

Worn or damaged hoses can lead to leaks themselves, compromising your detection efforts. By ensuring all components are in good working condition, you can rely on your refrigerant leak detector to provide accurate and timely results.

Is there a role of hoses in leak detection?

Hoses play a pivotal role in the leak detection process, serving as the conduit between the leak detectors and the HVAC systems.

They enable the flow of tracer gases necessary for identifying leaks, making them an integral part of the detection system.

The choice of hose material is crucial, as certain materials can withstand higher pressures and resist chemical degradation, ensuring accurate leak detection.

How to choose the appropriate hose material?

Choosing the appropriate hose material significantly influences leak detection effectiveness. Materials that resist chemical degradation provide more reliable performance over time.

Flexible hoses facilitate movement and access in tight spaces, making it easier to perform leak tests in various HVAC system configurations.

Hoses designed for leak detection must be both flexible and durable to maintain their structural integrity under pressure.

Using the correct hose diameter enhances the accuracy of leak detection by optimizing the flow rate of the refrigerant.

High-quality hoses are designed to minimize the risk of leaks themselves, which is vital for effective leak detection processes.

Ensuring your hoses are in good condition and suitable for the task greatly improves the reliability and accuracy of your leak detection efforts.

What are the benefits of Regular Leak Detection in HVAC Systems?

Regular use of leak detectors avoids energy losses and maintains HVAC system performance. Refrigerant leaks can lead to increased energy costs and environmental damage, making early detection critical for both economic and ecological reasons.

Implementing a leak detection system can result in significant cost reductions by minimizing refrigerant loss and improving energy efficiency.

Additionally, regular leak detection ensures compliance with environmental regulations, further protecting your business from potential fines and legal issues.

📌 By focusing on performance metrics

We can create healthier environments for humans, reducing the prevalence of health issues related to poor building performance.

Early Identification

Early identification of leaks enhances energy efficiency and lowers operational expenses, contributing to the overall sustainability of HVAC systems.

Continuous monitoring is a method for early identification of leaks, ensuring timely detection and resolution. Moreover, using leak detection systems improves safety for occupants by preventing the release of harmful refrigerants.

Conducting leak detection on your own offers flexibility, allowing you to address minor issues promptly and save on professional service costs.

Regular leak detection ensures HVAC systems operate at peak efficiency, providing comfort and safety while also protecting the environment.

The benefits of consistent monitoring and maintenance cannot be overstated, making it a vital practice for any HVAC professional or homeowner.

Summary

HVAC leak detectors are vital tools for maintaining system efficiency and environmental health. One key benefit of using leak detectors is ensuring compliance with environmental regulations.

Understanding the different types of refrigerant leak detectors, their key features, and how to use them properly ensures accurate and effective leak detection. Regular maintenance of these tools, along with proper hose selection, further enhances their reliability.

The benefits of consistent leak detection are manifold, from improved energy efficiency to cost savings and enhanced safety.

Whether through DIY methods or professional services, detecting and addressing refrigerant leaks promptly is essential for the longevity and performance of HVAC systems.

📌 Key Takeaway

Embrace the power of refrigerant leak detectors to keep your HVAC systems running smoothly and sustainably.

Frequently Asked Questions

Why are HVAC leak detectors important?

HVAC leak detectors are essential for promptly identifying refrigerant leaks, which can hinder system efficiency and pose environmental risks. By detecting these leaks early, they ensure optimal system performance and help reduce energy expenses. Additionally, HVAC leak detectors are crucial for home use, ensuring safety and efficiency in residential environments.

What types of leak detectors are available for HVAC systems?

Various leak detectors for HVAC systems include electronic detectors such as infrared, heated diode, and corona discharge, along with ultrasonic, dye-based, and halide detectors, and then there is the FLIR type cameras.

Each type offers unique advantages tailored to specific detection needs.

We are on a mission to redefine refrigerant leak detection.

Key Features of an Effective Refrigerant Leak Detector

A reliable refrigerant leak detector should be accurate, fast, and easy to use, helping technicians quickly locate leaks with minimal hassle. Here’s what to look for:

Data Logging & Connectivity (Premium Feature)

Some models offer Bluetooth/Wi-Fi integration for compliance tracking and proactive maintenance.

High Sensitivity & Accuracy

Detects leaks as small as 0.1 oz/year, with adjustable sensitivity for precision.

Fast Response & Recovery

Instant feedback ensures quick pinpointing without delays.

Multi-Gas Compatibility

Works with HFCs, HFOs, CO₂ (R-744), ammonia (R-717), and hydrocarbons using NDIR or Heated Diode sensors.

Clear Visual & Audio Alerts

Color-coded indicators, numeric readouts, and audible/vibration alarms enhance usability.

Durability & Ergonomics

Lightweight, rugged, with flexible probe tips for tight spaces.

Long Battery Life & Portability

Rechargeable batteries with auto-shutoff prevent downtime.

The right detector depends on system size, refrigerant type, and usage needs.

Choosing the best tool ensures faster leak detection, reduced refrigerant loss, and regulatory compliance.