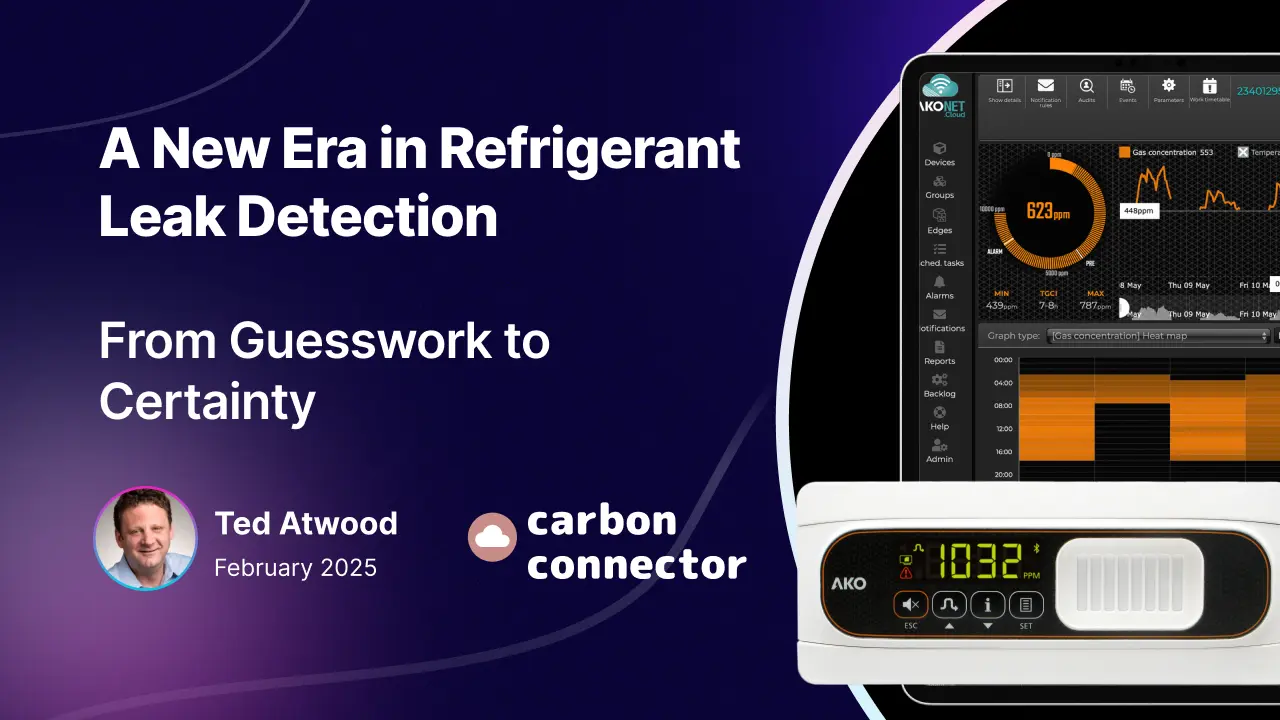

A New Era in Refrigerant Leak Detection: From Guesswork to Certainty

A Commitment to Stopping Refrigerant Leaks and Transforming Early Detection

Every year, 99.9% of refrigerants are vented into the atmosphere, fueling the climate crisis and creating operational and financial challenges for businesses worldwide.

This isn’t just an environmental problem—it’s a costly reality for grocery retailers, food manufacturers, and industrial operators who struggle to maintain compliance, prevent downtime, and manage rising refrigerant costs.

And in an industry already under pressure, the workforce shortage only worsens the problem.

Today, there are over 37,000 open jobs in the HVAC/R industry, with just 350,000 technicians trying to keep more than 200 million cooling appliances running.

Training new talent takes time, and many companies are stretched thin. As a result, technicians are forced to operate in a reactive cycle, responding to problems instead of preventing them.

Effective leak detection is critical for safety and optimal system performance, especially with the transition to low GWP refrigerants and the use of mildly more flammable refrigerant types like propane and A2L.

Be part of the movement to reduce leak rates, simplify compliance, and revolutionize refrigerant management.

Meet us at Booth 1286 during the 2025 AHR Expo in Orlando, February 10-12.

Table of Contents

TogglePartnerships drive Ako.

AKO has been committed to solving this problem for years, partnering with incredible U.S. and European grocers and cold supply chain companies to create smarter, more effective refrigerant leak detection solutions. At Carbon Connector, Effective Leak Detection has been one of our core missions since early 2011.

But this isn’t just a recent idea—it’s been a year-long journey of collaboration, learning, and proof of performance.

AKO also plays a crucial role in transitioning from older refrigerant technologies like R404A to newer, more environmentally friendly options such as R134a, driven by various regulatory pressures and environmental concerns. Our devices are configurable and easy to install, move, and keep using, even when transitioning to newer refrigerants.

A Year of Collaboration & Discovery

This journey began a year ago when I met Jordi and Javier from AKO at the Chicago AHR show. From that first conversation, it was clear that we shared a vision: leak detection had to improve—not just with better technology but with real-world solutions that our partners could trust.

For 12 months, we worked with their team—Jose Luis and Rodion—testing devices across the U.S., refining market knowledge, and putting detectors in the hands of businesses that desperately needed them.

And what we found was shocking.

Most businesses had lost confidence that leak detection could improve. Years of poor-performing detectors and high costs had made them skeptical.

They assumed that improving leak detection would be expensive. A device that was a fraction of the price of their current systems couldn’t possibly work better—right?

State-by-state testing proved otherwise. No matter the regulatory environment, businesses were surprised, then amazed, at how well AKO’s leak detectors performed.

What started as cynicism quickly turned into belief—because when you see a problem before it becomes a costly crisis, early detection proves critical to the technology’s effectiveness.

Effective leak detection is critical for safety and optimal system performance, especially with the transition to low GWP refrigerants and the use of mildly more flammable refrigerant types like propane and A2L.

Be part of the movement to reduce leak rates, simplify compliance, and revolutionize refrigerant management.

Meet us at Booth 1286 during the 2025 AHR Expo in Orlando, February 10-12.

Leak Detection That Drives Operational Performance

Leak detection is about more than just regulatory mandates—it’s about proactive maintenance, cost reduction, and ensuring refrigeration systems perform at their best.

The industry standard for leak detection has been ineffective for years—only 4% of refrigerant leaks are detected before they impact system performance.

Even worse, less than 1% of leak sensors and detectors are properly calibrated and maintained, making them unreliable when businesses need them most. Without calibration, sensors degrade, leading to false alarms, missed leaks, and wasted service calls.

With AKO Sentry, we’ve changed that.

Our solution detects and targets leaks before they lead to equipment strain, emergency service calls, or regulatory violations. But we looked beyond the devices (regardless of how proud we are of the technology) and how we could close the gaps between effective detection and time to roll a truck.

So, we pivoted from being device-centric to being results-oriented by leveraging our team of experts committed to supporting our partners in the field. That required us to look at three key aspects of the leak detector performance: calibration, report generation, and escalation notifications.

Every interaction had the same result: The devices were necessary, but here are the three hurdles that business as usual had not been solving:

- Outdated tech – they had plenty of devices, but they lacked any confidence in the results they provided. Most units had never been calibrated, and even fewer had been serviced; the old tubing-style detectors were damaged, the tubes were moved, or the pumps that moved the samples were broken, so the source material never made it to the detector.

- Data fatigue – some of these programs had 200 detectors and 1000 data points a day coming in, and no one could make the diagnosis, so they turned off the alarms, ignored alerts, and we saw ppm thresholds that never went to 0.

- Skills gap – review of every leak notification takes time. You have to review logs, compressor operations, and system function before you can accurately diagnose a leak and that involves about 30-40 data points if you own the unit that’s one thing, but if you are the service provider, you might have 300 of these to look at and there not enough hours in the day

Universally, everyone knows that effective leak detection is essential for optimal performance and enhancing safety by preventing potential fire hazards and health risks associated with flammable refrigerants like A2L and natural refrigerants like CO2. One partner said it best,

” We need a 24-hour sentry to watch over our equipment and let us know when we have to get back here; we need these devices to be an extra set of eyes so we don’t get caught off guard by a leak.”

Making a difference

Target Leaks Early — Be a team player

That partner’s need became our North Star mission, and we started to look beyond our technology and see where we could provide value in the chain between detecting leaks and asking the techs to go investigate.

Our entire priority ranking system changed, and rather than just selling devices that detect leaks, we were now using our own equipment and instead designing a solution to detect and address 85% of refrigerant leaks before they impact system performance—a game-changing improvement over the industry standard of just 4%. Early detection is crucial for safety and efficiency, especially in residential settings, where it can protect against fire hazards and health risks.

Our partners asked us to look at 5 key things:

Eliminate Faulty Sensors & False Alarm

Help them know when service is needed, establish trust and confidence, and keep detectors accurate and compliant. This will ensure real leak detection instead of unreliable alerts.

Help reduce false alarms – and, in turn, Reduce Unnecessary Truck Rolls.

By catching leaks early and accurately, we help businesses avoid emergency service calls, reduce technician workloads, and ensure repairs happen on schedule.

Find leaks early and confidently – So they can Optimize Refrigeration System Performance

Leaks that are detected yet go unrecognized force refrigeration systems to work harder, increasing energy consumption, wear and tear, and long-term costs. AKO Sentry ensures systems run at peak efficiency by preventing leaks before they cause operational disruptions.

Empower an Overworked Workforce

With 37,000 open jobs and not enough skilled technicians, businesses need solutions that lighten the load. AKO Sentry acts as an extra set of eyes and ears, ensuring leaks don’t go unnoticed, helping teams prioritize repairs, and making every technician more effective.

Help them develop an affordable, manageable calibration regimen.

Without proper maintenance, calibration, and proactive monitoring, leak detection becomes another unreliable mechanical device. AKO Sentry is different. We combine innovative technology with expert oversight to ensure daily accurate, actionable leak detection.

Effective leak detection is critical for safety and optimal system performance, especially with the transition to low GWP refrigerants and the use of mildly more flammable refrigerant types like propane and A2L.

Be part of the movement to reduce leak rates, simplify compliance, and revolutionize refrigerant management.

Meet us at Booth 1286 during the 2025 AHR Expo in Orlando, February 10-12.

While EPA regulations require leak detection, most owners and operators are more focused on preventing equipment failure before it disrupts operations.

In an industry where there aren’t enough technicians to cover all the necessary work, businesses need solutions that help them stay ahead of problems rather than constantly reacting to emergencies.

With limited time during the workweek and a growing labor shortage, early leak detection isn’t just about compliance—it’s about keeping systems running efficiently with the workforce available.

The AKO 5 Points of Service: Built from Real-World Feedback

Over the past year, we’ve listened to people like Bryan Williams from Harris Teeter’s professionals who rely on leak detection but have been frustrated by unreliable sensors, false alarms, and compliance challenges.

Their input has shaped how we deliver not just a product but a full-service solution that simplifies operations and enhances compliance.

Here’s how AKO’s 5 Points of Service are designed to ensure that leak detection works better, smarter, and faster for our customers:

1. Managed Service: Real People Reviewing Real Data

- Our team actively monitors reports, reads alerts, and notifies you of real concerns before they escalate.

- We help service providers prioritize leaks, ensuring that technician resources are used efficiently. Monitoring air quality is crucial in detecting refrigerant leaks, and ensuring efficient operation and safety.

- We are not just a device—we’re a trusted partner in proactive leak detection and compliance.

2. Annual Calibration Support — No More Unreliable Sensors

- We provide full calibration support, ensuring sensors stay accurate and compliant. Maintaining sensor accuracy is critical for optimal performance and safety.

- Need hands-on assistance? We coordinate services, connect customers with experts, and ensure compliance-ready calibration every year.

3. Compliance Monitoring & Leak Profiling

- We track leak events against regulatory thresholds to help businesses avoid violations before they happen. Early detection of refrigerant leaks is crucial in this process, as it allows for timely identification and resolution, thereby preventing potential regulatory violations.

- We provide detailed reporting and compliance guidance tailored to evolving regulations.

4. Nationwide Connectivity with T-Mobile for Always-On Monitoring

- Devices securely connect to a nationwide Wi-Fi infrastructure, ensuring seamless, real-time monitoring.

- No need for manual network setups — connect and monitor effortlessly from anywhere.

5. Field-Ready Devices Pre-Registered Before Shipping

- No complicated configurations — just install and connect.

- Devices arrive fully linked to the AKO monitoring system, ensuring immediate activation.

- Adapting to new refrigerant standards, such as the transition from R12 to R134a, is crucial for both efficiency and compliance.

This has been a transformative year for all of us—the AKO team, our team at Carbon Connector, and the many partners who have helped drive this massive shift in the way we think, act, and innovate. Together, we’ve reshaped an industry, moving beyond the outdated, business-as-usual approach of “hoping to find leaks” and instead building a high-confidence, trust-based partnership model that delivers real, measurable improvements in leak detection and compliance.

The shift from low-confidence, reactive leak detection to a proactive, trusted solution that delivers results has already made a huge impact—and it’s just the beginning.

We can’t wait to see you all at AHR, share our journey, and continue working together to reduce leaks and build a more effective, efficient future.

Join Us in Stopping Refrigerant Leaks

- Meet Us at Booth 1286 at the AHR Expo (Feb 10-12) to learn more.

- Scan the App to see real-time leak detection in action.

- Register for the Blog to stay ahead of compliance and industry trends.

We are on a mission to redefine refrigerant leak detection – join us.