Refrigerant Leak Detection as a Service

Table of Contents

ToggleEvolving Refrigerant Leak Detection

Carbon Connector’s LDaaS Pioneers a Smarter, Collaborative, and Insight-Driven Approach

A Learning Moment for the Industry

Let’s face it: The world of refrigerant leak detection has long been riddled with failure points, not because of the technology itself but because of how it was introduced, misunderstood, and often ignored. Sensors were installed with the best intentions but left unmonitored.

Technicians grew weary of false alarms. Facilities teams stopped trusting the tools meant to help them.

We’ve all heard the stories: the walk-in freezer that went down on a Saturday night, the technician who called in during their kid’s baseball game, or the holiday dinner interrupted by a refrigeration failure at a grocery store.

🚧 Behind every leak is not just a system failure

it’s a human moment disrupted. And that’s what we set out to change.

When we began this journey, we didn’t start with a product. We started with questions. We sat across from exhausted technicians, listened to contractors juggling compliance logs, and met with corporate leaders who wanted to align operations with ESG goals but didn’t know where to begin. We crossed the Atlantic, learning from European cold-chain operators who had already pioneered smarter detection approaches. Each step revealed a shared frustration and a deep desire for something better.

LDaaS – Leak Detection as a Service – is the outcome of that journey. It’s a story of collaboration, insight, and persistence. It’s not just a new tool. It’s a new chapter.

But LDaaS is also a mirror—and a test.

Jack Welch, the legendary CEO of GE, believed that leadership wasn’t about managing processes. It was about identifying and developing A players — people with vision, energy, courage, and the will to execute. In his world, if a leader didn’t elevate talent, they were failing.

So, let’s ask ourselves: What is refrigerant leak detection really revealing about the state of facility leadership today?

Billions are being spent on ESG, sustainability, and operations. The world is screaming for help. Yet one of the clearest, most solvable threats to environmental performance — refrigerant emissions — continues to go unnoticed or unmanaged.

The tools for detecting leaks exist. The money is there. But too often, the leadership to act with urgency is missing.

Tired of Refrigerant Leak Emergencies?

LDaaS isn’t just a technological leap forward. It’s a rallying point for leaders who choose to see. It’s a system that identifies the problems, supports the people closest to them, and empowers better decisions at every level. It’s what happens when you stop blaming the tools and start building the system.

The Problem: A System Ripe for Disruption

We’re not here to blame the hardware. The problem isn’t the sensor – it’s the system around it: Integrated monitoring solutions, such as a central control system, can enhance safety and regulatory compliance by streamlining management and alerting for hazardous environments.

Neglected Devices

Leak detectors often go unmaintained, degrading accuracy.

Untrusted Results

Years of false alarms have conditioned teams to ignore real issues.

Alert Fatigue

Constant pings drain attention and morale.

Reactive Operations

Leaks are addressed only after they’ve become expensive problems.

Lack of Context

Data without human insight leads to confusion instead of clarity.

Every facility manager we met had a story to tell. A crisis narrowly avoided. Or one that wasn’t.

These were systems designed to support operations, but in practice, they added noise instead of value.

And every technician we spoke to wanted the same thing: tools they could trust and leaders who would back them up.

Our Journey to a Solution

LDaaS emerged from dozens of interviews, long nights in server rooms, and field testing in real facilities where failure wasn’t hypothetical. We built this system alongside people who were ready to stop apologizing for leaks and start preventing them. Commercial refrigeration systems are complex and prone to leaks, making regular monitoring essential to ensure efficiency and prevent costly issues.

When we discovered AKO – a Spanish engineering firm with over a decade of success in European cold-chain compliance – the model took shape. Their NDIR sensor technology delivered not just precision but stability. It held up in the elements. It earned trust.

We saw an opportunity to pair their proven tools with something that had long been missing in North America: a system built around people, insights, and proactive service.

LDaaS: A Strategic Shift in Refrigerant Leak Detection Services, A True Partnership

LDaaS is not a product drop-off. It’s a collaborative, service-first model that blends AKO’s precision sensor platform with Carbon Connector’s operational intelligence and field-level support.

What we’ve built is:

Collaborative Monitoring

AKO’s and our teams validate anomalies and remove noise.

Direct Tech Communication

Our analysts work side by side with your field technicians.

Proactive Problem Solving

Subtle leaks are detected before they escalate.

Contextual Reporting

Alerts come with recommended actions, not question marks.

Lifecycle Support

From installation to documentation, we stay involved.

Outcome-Oriented

We measure success by leaks solved, not devices sold.

This is the system A players have been waiting for. Our refrigerant leak detection services emphasize the importance of regular testing and utilize advanced detection technology to ensure that both residential and commercial systems operate efficiently and safely.

What LDaaS Actually Is

LDaaS is not a device. It’s a co-pilot.

At the core: AKO’s NDIR (Non-Dispersive Infrared) sensor platform:

- Detects minor refrigerant losses at < 1% thresholds

- Stable in all environments

- Configurable for various refrigerants and asset types

- Refrigerants accurately detected to enhance refrigerant management and ensure compliance with safety and emissions regulations

Overlaid with Carbon Connector’s proprietary service framework:

- Smart Signal Logic to reduce false alarms

- Real-time triage and contextual alerting

- Human Interpretation to turn data into action

Without software, this would be just another sensor. With it, LDaaS becomes a living system—filtering signals, prioritizing responses, and closing the loop between insight and action.

There’s software to this hardware

Although AKO is not a software company at its core, it understood something that many in the industry overlooked: the future of leak detection doesn’t stop at the sensor. It starts with connection.

That’s why they built AKOCloud — a purpose-built application designed not to show off software skills but to solve a real problem: making sure the right people stay informed in real-time without adding noise.

AKOCloud was born out of necessity. Their engineering teams saw how fragmented systems were in the field. They listened to technicians who struggled with multiple interfaces, disconnected tools, and reports that didn’t reflect the full story.

They recognized that even the most accurate sensor was useless without an intelligent, accessible platform to interpret and act on the data.

Perhaps most importantly, they understood the complexity of building software that could safely and reliably integrate with Building Management Systems (BMS) without compromising security. In a world where cyber threats are real, and operational technology must be safeguarded, AKOCloud was built to be dependable, secure, and easy to connect.

This isn’t a flashy SaaS product looking for a problem. It’s a working platform created by a team that lives in the trenches of refrigeration and knows exactly what’s at stake.

AKOCloud brings LDaaS to life by:

- Delivering real-time visualization of sensor activity and system health

- Offering role-based dashboards so techs, managers, and compliance officers each see what matters

- Sending triaged alerts with actionable insights instead of raw data dumps

- Storing historical event logs for audit readiness and leak pattern learning

- Enabling secure, API-based integration with existing enterprise systems, from CMMS to ESG platforms

With AKOCloud, data doesn’t sit idle. It moves, informs, and enables decisions. It transforms LDaaS into a true operational partner, connecting people, insights, and actions seamlessly across your organization.

AKOCloud isn’t about showing off software.

It’s about showing up for the people who keep systems running.

Ready to Improve Your ESG Performance?

Tariff Resilience Through Domestic Assembly and Support Strategy

As global supply chains tighten and tariffs on refrigerant components and sensing technologies continue to rise, many vendors are scrambling to protect their margins. But at Carbon Connector, we’ve already accounted for this.

In early 2024, we strategically decided to localize key aspects of our manufacturing and assembly. By establishing U.S.-based operations in Chatham, Massachusetts, and Southern Florida, we positioned ourselves ahead of the curve, ensuring that new rounds of import tariffs have no material impact on our pricing or delivery timelines.

This move wasn’t just about cost protection. It was about control, accountability, and long-term support. Our domestic facilities allow us to rapidly prototype, configure, and scale sensor assemblies to meet the diverse needs of our partners. It also ensures overseas logistics or volatile trade policies don’t slow down compliance-driven innovation.

Our U.S.-based team is fully equipped to interpret, scale, and periodically analyze detection results. This means clients receive not only real-time alerts but regular intelligence reports grounded in field data and operational context without added cost or tariff-driven delays.

Leak detection isn’t just about sensors. It’s about strategy. And we’ve built ours to last.

The LDaaS Difference

1. Intelligent Monitoring

LDaaS doesn’t create noise. It creates meaning. LED indicators deliver quick visibility. Dashboards show the whole picture.

2. Empowering Technicians

When Welch talked about A players, he meant people who step up. Our system equips them with the context, insight, and credibility to lead.

3. Prevention Over Reaction

Detecting refrigerant loss at 1% means less downtime, less spoilage, and fewer late-night calls. Effective leak detection not only contributes to cost savings but also ensures compliance with legal regulations, showcasing the dual benefits of maintaining high system efficiency.

4. True Service Model

We stay engaged long after installation. The system evolves. Leak profiles improve. People learn.

5. Actionable Insights

Every alert becomes a learning moment. Every log becomes a compliance asset.

It’s a Poor Craftsman That Blames His Tools

Welch would have seen the lesson here.

The tool isn’t the problem. The system is.

LDaaS restores trust between the technician and technology. It creates a feedback loop that supports performance. It gives teams the visibility, support, and recognition they deserve.

We don’t blame the craftsman. We build systems that make the craft visible.

Why Refrigerant Leak Detection Matters

Leaks impact more than equipment:

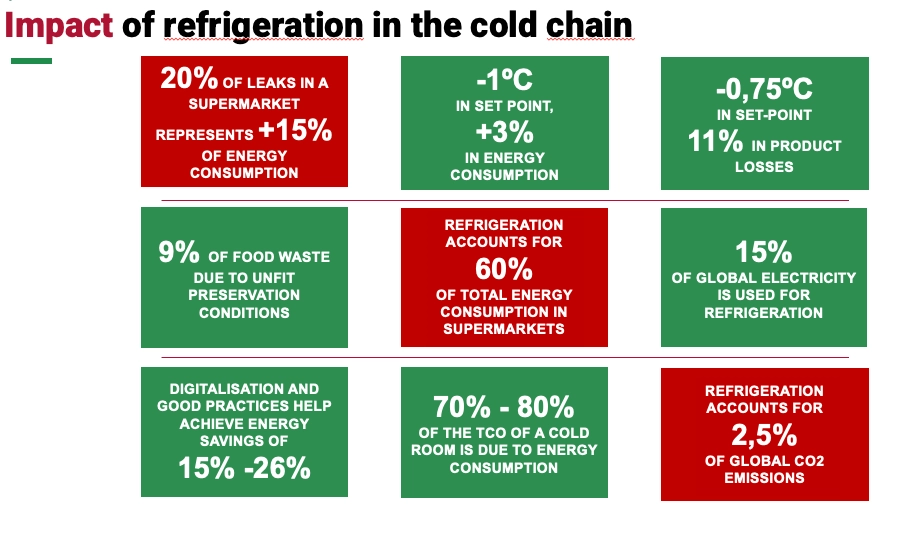

- Wasted energy = higher bills

- Lost product = revenue loss

- Environmental damage = GHG emissions

- Regulatory fines = non-compliance risk

HVAC and refrigeration systems are crucial in this context, as leaks in these systems not only reduce efficiency but also contribute significantly to environmental issues due to the release of HFC refrigerants.

You can’t manage what you can’t see. LDaaS changes that.

Prevent Equipment Breakdowns and support your workforce.

Preventing equipment breakdowns and saving labor are key bottom-line issues and are two significant benefits of regular refrigerant leak detection. Refrigerant leaks can cause equipment to work harder, leading to increased energy consumption and higher utility bills and shortening the equipment components’ life. So, by detecting and repairing leaks promptly, you can prevent equipment breakdowns, reduce waste, and lower costly truck rolls.

In commercial settings, refrigerant leaks can have a significant impact on equipment performance and energy efficiency. A single leak can cause a system to consume up to 25% more energy, leading to increased costs and a larger carbon footprint. Regular refrigerant leak detection can help identify and address leaks, ensuring that your equipment operates efficiently and effectively.

To prevent equipment breakdowns and save energy, it’s essential to implement a regular refrigerant leak detection program. This can include:

- Regular inspections of refrigerant lines and equipment

- Use of advanced leak detection technology, such as electronic sensors and thermal imaging cameras

- Prompt repair of detected leaks

- Regular maintenance of refrigeration equipment to prevent leaks and ensure optimal performance

By prioritizing refrigerant leak detection and repair, you can prevent equipment breakdowns, save energy, and reduce your environmental impact.

Methods of Detection

Method |

Use Case |

Limitations |

|

Electronic

|

General Purpose

|

Prone to noise

|

|

Ultrasonic

|

Detects escaping gas

|

Needs quiet environment

|

|

Infrared (NDIR)

|

More precise

|

Higher initial cost

|

|

Acoustic

|

Tuned to system sounds

|

Niche use

|

|

Soap Bubbles

|

Spot-checks

|

Manual, not scalable

|

|

Versatile Leak Detection Device

|

Detects refrigerants and combustible gases

|

Higher initial cost

|

AKO chose NDIR for its precision, consistency, and field readiness.

The Human Factor: Why It Still Matters

One truth remains for all the talk of automation, AI, and sensor technology: humans still anchor the system. The success of any leak detection program — no matter how advanced — hinges on the clarity, communication, and confidence of the people involved.

In today’s facilities, machine rooms are often unmanned. Technicians cover vast areas, sometimes responsible for multiple sites. Emergencies don’t wait for shift changes, and problems don’t announce themselves. But this is exactly where LDaaS steps in.

LDaaS was designed with this human reality in mind.

It becomes a shared language, powered by software but spoken through every technician, analyst, and executive who relies on timely, intelligent insights.

Our detectors act as an extra set of eyes and ears in the field. They sit quietly, listening, watching, learning — sentinels ready to speak up only when it matters. And when they do, the system doesn’t just shout; it delivers context, prioritizes response, and connects people to action.

This allows:

- Unmanned spaces to remain protected

- Technicians to focus on solving, not searching

- Supervisors to trust the data without second-guessing

- Leadership to understand where and why issues are emerging

By honoring the human role, not replacing it, LDaaS becomes more than just detection. It becomes a bridge between the physical world and the people managing it.

Technology enables the insight. But it’s still people who turn that insight into progress.

In the end, the human factor isn’t a vulnerability.

It’s the value.

Indoor Air Quality and Refrigerant Leaks

Refrigerant leaks can have a significant impact on indoor air quality. When refrigerants leak, they can release harmful gases into the air, which can pose health risks to occupants. Refrigerant leaks can also contribute to the growth of mold and bacteria, which can exacerbate respiratory issues and other health problems.

To maintain good indoor air quality, it’s essential to detect and repair refrigerant leaks promptly. Regular refrigerant leak detection can help identify leaks and prevent the release of harmful gases into the air. Additionally, ensuring that your refrigeration equipment is properly maintained and serviced can help prevent leaks and minimize the risk of indoor air quality issues.

To maintain good indoor air quality, you can:

- Regularly inspect refrigerant lines and equipment for signs of leaks

- Use advanced leak detection technology, such as electronic sensors and thermal imaging cameras

- Ensure that your refrigeration equipment is properly maintained and serviced

- Use air purification systems to remove harmful gases and particles from the air

By prioritizing refrigerant leak detection and repair, you can help maintain good indoor air quality and promote a healthy and safe environment for occupants.

Where LDaaS Thrives

|

Grocery

CARB compliance, protect perishables, reduce callouts

|

Real Estate

Open system, works with any label vendor

|

Data Centers

Prevent thermal drift, maintain uptime, audit-ready.

|

Regulatory & Boardroom Alignment

Federal |

State |

Executive Value |

|

EPA 608

Tracking, logging, repair verification

|

CARB (CA)

Inspection and monitoring requirements

|

Track ESG performance

|

|

AIM Act

Emissions reduction support

|

CCA (WA)

HFC compliance

|

Surface capital risks early

|

|

SEC Disclosure

Prepares for Scope 1 reporting

|

CLCPA (NY)

Emissions tracking and reduction

|

Empower facilities with real-time data

|

Gas detection systems facilitate compliance with refrigeration safety codes simple, making it easier to meet safety regulations in mechanical equipment rooms.

Leak detection isn’t just an operations challenge anymore. It’s a C-suite priority.

Leak detection isn’t just an operations challenge anymore. It’s a C-suite priority. Through AKOCloud, LDaaS becomes a verifiable source of truth—automatically recording compliance events, surfacing emissions trends, and equipping leadership with the data needed to report, respond, and plan.

Factors to Consider When Selecting a Service Provider

When selecting a service provider for refrigerant leak detection and repair, there are several factors to consider. These include:

- Experience and expertise in refrigerant leak detection and repair

- Use of advanced leak detection technology, such as electronic sensors and thermal imaging cameras

- Compliance with refrigeration safety codes and regulations

- Ability to provide prompt and efficient service

- Competitive pricing and cost savings

- Reputation and customer reviews

- Certification and training of personnel

- Availability of remote monitoring solutions and emergency response plans

By considering these factors, you can ensure that you select a service provider that meets your needs and provides effective refrigerant leak detection and repair services.

In addition to these factors, you should also consider the following:

- The service provider’s ability to detect refrigerants accurately and enable cost savings

- Their experience with refrigeration systems and equipment

- Their knowledge of refrigeration safety codes and regulations

- Their ability to provide effective refrigerant management and leak detection solutions

- Their use of combustible gas detectors and other safety equipment

- Their ability to provide LED status indicators and other visual alerts

- Their experience with control systems and refrigeration equipment

By considering these factors, you can ensure that you select a service provider that provides effective refrigerant leak detection and repair services and promotes a safe and healthy environment for occupants.

Pilot Program: Try Before You Buy

We offer a no-risk trial:

- Pay a small deposit

- Get a configured sensor

- Validate in the field

- If satisfied, complete the purchase

- If not, return it for credit

No fine print. Just results.

Powered by Carbon Connector

This isn’t a sensor. It’s a system of action.

Built on trust. Grounded in insight. Refined by people who care. LED status indicators provide users with a clear, at-a-glance overview of the system’s performance and status, enhancing monitoring and management capabilities.

LDaaS is the result of a journey—one that began with listening, learning, and the simple belief that leak detection could be something better. And now, it is.

The world doesn’t need more tools. It needs more leaders. LDaaS is where both come together.

Join the conversation! What’s your biggest challenge with compliance in HVAC/R right now?

Prevent Leaks, Reduce Costs, Improve Performance

Your Facilities Deserve Reliable Leak Detection